Lightweight 6x4 Super

Page 56

Page 59

Page 60

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

Mastiff by Gibb Grace

New cabs and more robust engines for the Redlines from Bathgate

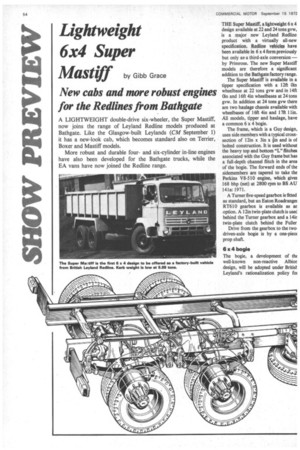

A LIGHTWEIGHT double-drive six-wheeler, the Super Mastiff, now joins the range of Leyland Redline models produced at Bathgate. Like the Glasgow-built Leylands (CM September 1) it has a new-look cab, which becomes standard also on Terrier, Boxer and Mastiff models.

More robust and durable fourand six-cylinder in-line engines have also been developed for the Bathgate trucks, while the EA vans have now joined the Redline range.

THE Super Mastiff, a lightweight 6 x 4 design available at 22 and 24 tons gvw, is a major new Leyland Redline product with a virtually all-new specification. Redline vehicles have been available in 6 x 4 form previously but only as. a third-axle conversion— by Primrose. The new Super Mastiff models are therefore a significant addition to the Bathgate factory range.

The Super Mastiff is available in a tipper specification with a 12ft Oin wheelbase at 22 tons gvw and in 14ft Oin and 16ft 4in wheelbases at 24 tons gvw. In addition at 24 tons gvw there are two haulage chassis available with wheelbases of 16ft 4in and 17ft 11in. All models, tipper and haulage, have a common 6 x 4 bogie.

The frame, which is a Guy design, uses side members with a typical crosssection of 12in x 3in x On and is of bolted construction. It is used without the heavy top and bottom "L" flitches associated with the Guy frame but has a full-depth channel flitch in the area of the bogie. The forward ends of the sidemembers are tapered to take the Perkins V8-510 engine, which gives 168 bhp (net) at 2800 rpm to BS AU 141a: 1971.

A Turner five-speed gearbox is fitted as standard, but an Eaton Roadrangei RT610 gearbox is available as an option. A 12in twin-plate clutch is usea behind the Turner gearbox and a 14in twin-plate clutch behind the Fuller Drive from the gearbox to the twodriven-axle bogie is by a one-piea prop shaft.

6 x 4 bogie

The bogie, a development of tilt well-known non-reactive , Albior design, will be adopted under Britist Leyland's rationalization policy fol -se on . all Glasgow, Bathgate and eyland 6 x 4 vehicles.

It is a fully compensating design i before but now uses compression ruts in place of the tension members sed previously. Articulation of the ogie is unchanged; it can cope with a Laximum 6in vertical step between des along the chassis and up to 10 ig articulation between axles across ie chassis.

Visually the biggest change is that 1 the bracketry and interconnecting vers are now outside the frame, aving the inside free apart from the ormal cross-members.

Simplified maintenance has been the Lain aim of the new bogie, and this has eon assured by improved detail design I the shackles and pins. The main aural bearing now has grease cups at rther end and extra cross-drillings i the shafts to ensure ample lubriation over their whole length. Shackle ins have had their phosphor bronze ushes replaced by Nylatron bushes bich do not require greasing.

The shackles themselves were made p from two separate parts but these re now replaced by one "H" shaped nzing. These give the springs and the ides much greater sideways stability rid further reduce wear on the spring ye bushes. Shackle brackets and the vet arms for the compensating techanism have been redesigned and inplifiecl but they still pick up through is frame with substantial tubular ross-members as before. A notable advantage of the new design is that because the compensating mechanism is now outside the frame, no large hole is needed in the frame. The smaller brackets have in fact enabled the top of the frame members to be lowered 2in.

Spares eased The rationalization programme has also spread to the springs and now the springs of Bear, Bison, Super Buffalo, Reiver and Super Mastiff are similar and will thus considerably ease the spare parts situation.

The Super Mastiff uses Maudslay single-reduction axles with the bogie at the moment, but it is likely that eventually Albion hub-reduction axles will be used. The Glasgow-built axles are exactly the same as the Leyland ones and it would make sense to have only the one type throughout.

Full air dual-circuit brakes are fitted. Diaphragms in conjunction with spring brake units on both rear axles are used for primary braking and the spring brake units only for parking. • Cam-operated brake shoes operate 151in x 6in drums at the front axle and 15-4-in x in drums on the rear axles.

Cheaply uprated Plated weight of the front axle is 6.0 tons but the beam is rated at 6.5 tons, as are the standard springs, so a useful plating increase can be achieved quite cheaply by specifying suitable tyres. Power-assisted steering is fitted as standard. The rear bogie, which has 4ft fin axle centres, has a rated capacity of 18.0 tons on 9.00 tyres: 10.00 tyres are available as an option and would increase the plated weight to 18.5 tons.

Driver comfort is well catered for in the facelifted Bathgate cab and the owner of a Super Mastiff will have the distinction of a new-look cab. A full description appears elsewhere in this supplement. The cab suits the Super Mastiff very well, as it has better approach angles than the Ergomatic type.

Kerb weight of the 12ft Oin-wheelbase 22-ton-gvw vehicle is 5.70 tons and that of the 24-ton-gvw vehicle is 5.85 tons, giving body payload allowances of 16.30 and 18.15 tons respectively. BRITISH LEYLAND engineers faced with the need to uprate the original fourand six-cylinder Austin engines for Redline vehicles have used the exercise as an opportunity to rationalize the bore and stroke dimensions of these two engines and at the same time eradicate the known in-service problem of cylinder block and head cracking. The problem was compounded by the fact that the engines are built on an existing transfer line at Bathgate, making fundamental changes impossible. However, by making the changes described here the original objectives have been achieved and the lighter Redline trucks now benefit from a muchimproved range of engines.

Externally the new 98 series engines do not show any marked alteration from the 3.8, 5.1 and 5.7 engines they replace, the only noticeable changes being to the injection pump, which is now a mechanically governed CAV DPA type, and to the waterpump housing.

The fuel-injection pump is driven '.from the gear train at the front of the block. An injection advance and retard control in the pump ensures the correct advance at all engine speeds and gives improved engine efficiency.

More metal Internally bore and stroke sizes have been rationalized to 98mm (hence 98 series) and 125mm respectively across both fourand sixcylinder engines. Previously these engines had 100 x 120mm and 95 x 120mm bore and stroke dimensions respectively. Both fourand sixcylinder engines are produced in a high and low rated form, the actual outputs being shown in graph form here. The low-rated version of the four-cylinder engine (designated 4/98) will not be used in trucks, but the high-rated versions will replace the previous 3.8-litre engine. The low-rated six-cylinder engine (6/98E) will take the place of the 5.1-litre engine and the high-rated six (6/98) that of the 5.7-litre engine.

The earlier 100mm bore engines suffered from cracking between the bores because there was insufficien metal in that area to withstanc thermal changes. By reducing tit bore from 100 to 98mm, castinl thickness has been increased b: 4mm (about 30 per cent) giving ; better heat flow in that critical are and a correspondingly improvec resistance to thermal cracking.

The cylinder head too has bee] modified to relieve local hot spots The injector bore has been /1101/C4 0.062in away from the valves b: altering its angle to the vertica from 22 deg to 21 deg; this amouni though seemingly small, has solvel the cracking problem in this area Inlet and outlet valves have beei enlarged and raised above the surfac

of the head instead of being flush as previously.

Longer life Exhaust valves are increased to 1.5in diameter and are now made from 21/4N material for improved life, they also now have replaceable alloyed-iron seats which improve engine life. Inlet valves are increased to 1.7in diameter and made from much harder EN 24 material. The cylinder gasket, often a problem area in diesels, has given no problems in service and remains unchanged in the new engines.

A paradox affecting the former engines, which suffered from overheating in cold climates and yet did not show this symptom in hot climates, posed a problem but this has now been identified and put right. During exhaustive tests it transpired that the single-element thermostat was closed or near closed for most of the time in low ambient temperatures and that the cross-sectional area of the by-pass duct was too low to allow proper coolant circulation. To solve the problem the by-pass from the thermostat housing to the water pump has been increased in cross-sectional area by 75 per cent. A larger bore pipe could not be located in the original position as it would have interferred with the alternator so it has been moved to the opposite side of the block.

Four-ringers

As a bonus the improved cooling has allowed the bottom scraper ring to be removed from the pistons. This is because the cylinder liner is now more evenly cooled and stays more circular. Four rings are now used; the top one is rectangular with a chrome insert, the second and third rings are unplated and have tapered faces for quick bedding in. The only scraper is positioned just above the gudgeon pin and is of conventional slotted design.

All these changes have been thoroughly tested before adoption and all the engines have satisfactorily passed the Leyland Group Standard Test which involves more than 1500 hours of duration and per-. formance testing. These engines are being built at Bathgate and will be available in all Bathgate-built trucks very shortly.