All-new Foden cab bristles with good points

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Sandbach company also produces an eight-speed gearbox for the Show and offers a torque converter

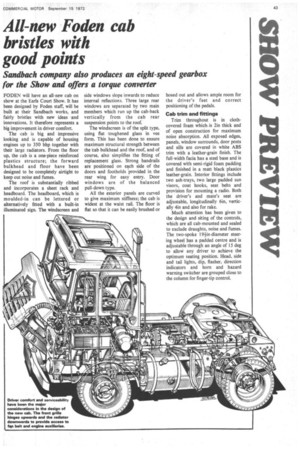

FODEN will have an all-new cab on show at the Earls Court Show. It has been designed by Foden staff, will be built at their Sandbach works, and fairly bristles with new ideas and innovations. It therefore represents a big improvement in driver comfort.

The cab is big and impressive looking and is capable of housing engines up to 350 bhp together with their large radiators. From the floor up, the cab is a one-piece reinforced plastics structure; the forward bulkhead and floor have been designed to be completely airtight to keep out noise and fumes.

The roof is substantially ribbed and incorporates a sheet rack and headboard. The headboard, which is moulded-in can be lettered or alternatively fitted with a built-in illuminated sign. The windscreen and side windows slope inwards to reduce internal reflections. Three large rear windows are separated by two main members which run up the cab-back vertically from the cab rear suspension points to the roof.

The windscreen is of the split type, using flat toughened glass in vee form. This has been done to ensure maximum structural strength between the cab bulkhead and the roof, and of course, also simplifies the fitting of replacement glass. Strong handrails are positioned on each side of the doors and footholds provided in the rear wing for easy entry. Door windows are of the balanced pull-down type.

All the exterior panels are curved to give maximum stiffness; the cab is widest at the waist rail. The floor is flat so that it can be easily brushed or

hosed out and allows ample room for the driver's feet and correct positioning of the pedals.

Cab trim and fittings Trim throughout is in clothcovered foam which, is 2in thick and of open construction for maximum noise absorption. All exposed edges, panels, window surrounds, door posts and sills are covered in white ABS trim with a leather-grain finish. The full-width facia has a steel base and is covered with semi-rigid foam padding and finished in a matt black plastics leather-grain. Interior fittings include two ash-trays, two large padded sun visors, coat hooks, seat belts and provision for mounting a radio. Both the driver's and mate's seat are adjustable, longitudinally 6in, vertically 4in and also for rake.

Much attention has been given to the design and siting of the controls, which are all cab-mounted and sealed to exclude draughts, noise and fumes. The two-spoke I 9i-in-diameter steering wheel has a padded centre and is adjustable through an angle of 15 deg to allow any driver to achieve the optimum seating position. Head, side and tail lights, dip, flasher, direction indicators and horn and hazard warning switcher are grouped close to the column for finger-tip control. Good dash layout The main instrument panel is divided into two areas. One is directly in front of the driver, viewed through the steering wheel. This provides only information which is essential to the driver while on the move — such instruments as speedometer, rev counter, air pressure gauges, water temperature and oil pressure gauges, and warning lights for turning indicators and main beam.

The other area of the panel is to the left and gives secondary information — its items include a battery condition gauge, switches for heater fan, panel, fog and spot lights. Both panels are cowled and both the padded facia and instrument bezels have a matt black finish to cut down reflections.

Two 6Kw fresh-air heater units are standard and give an infinitely variable distribution between screendemist and cab. Water flow to both heaters can be controlled from the same console to give any desired cab temperature. Heater vents are located at floor level. Swivelling eyeball vents are located at both ends of the facia which will demist quarter lights or provide hot or cold air directed as required.

Access for servicing and maintenance has been a key feature of the cab design. Two clips release the front lift-up grille which gives access to windscreen washer bottle; power steering pump reservoir, both heater units with attendant ducts and cables, air auxiliary feed block, electrical connections etc.

The radiator hinges forward after releasing the anchoring bolts. With the radiator lowered, access is given for fan removal or belt adjustment, and to the auxiliaries driven from the front end of the engine. Batteries are under the mate's floor and access for filling is through a removable panel.

For major work the cab can be tilted through 45 degrees. To do this two bolts must first be removed, then the cab can be tilted by hydraulic means. Before tilting it is necessary to lift the front cover and lower the radiator.

New eight-speed gearbox Foden has also announced an eight-speed version of its 12-speed gearbox which could eventually replace it altogether, as it has the same ratio spread and low first and reverse gear ratios.

The original 12-speed Foden box had a very wide ratio range but needed considerable driver experience to give the best results. At the Scottish Show last year, Foden announced a much simpler rangechange nine-speed version and while this box was popular with drivers because of its easier change sequence,, some operators complained because the very low first gear of 1225 to 1 had been dropped.

The new model 758 eight-speed box, although having one less gear, has the equivalent ratio range of the original 12-speed. The gear ratios provided are 12.25, 7.25, 4.90, 3.29, 2.20. 1.49, 1.00 and 0.77 to 1; reverse is again as the original box, 9.8 to 1.

The lower first gear does mean that the torque input rating is now limited to 7501b ft hut this will suit most engines up to 270 bhp. The gearbox is 38+in long and weighs 5701b.

Foden/Brockhouse torque converter

In another transmission development, Fadens, in close-co-operation with Brockhouse, have produced a torque converter designed for use with engines in the range of 270 to 350 bhp, which can be used in conjunction with the present Foden range of gearboxes. The converter has a stall torque of 2.4 times the engine torque and thus effectively doubles the overall gear ratio when starting from rest.

An oil-operated clutch is incorporated in the unit which locks out the converter when travelling at normal engine speed and thus improves efficiency. This clutch is electro-hydraulically controlled and is normally arranged to lock in at a speed of 1800 rpm when accelerating and unlock at a speed of 1600 rpm, when decelerating. It is also controlled so that during any gear-change the clutch is disengaged — and there is a delay before it locks up again after a gear change. This enables the converter to take up the drive immediately after gearchanging, andthus eliminate shocks to both engine and transmission line.

In, common with other torque converters, the excess heat generated when the converter is operating is dissipated by an oil to water heat exchanger and thence to the vehicle radiator, the radiator capacity being increased by approximately 30 per cent to cope with this condition. If, for any reason, the coolant temperature does become excessive, a temperature switch automatically locks out the converter and it will function purely as a mechanical drive until such time as the temperature falls to normal.

Immediately behind the torque converter is a normal Foden clutch suitably rated to deal with the increased torque, with an air-assisted clutch pedal in order to reduce the pedal load. • Gear-changing on the vehicle is carried out in exactly the same manner as for any other gearbox. so the driver does not have to learn any new techniques.

A torque converter has the advantage of protecting both engine and transmission line from the damaging effects of high torque fluctuations induced by misuse of the clutch. Further, since it acts as a slipping clutch, it is not necessary to declutch for temporary stops, but merely to apply the brakes. Stopping and starting on hills is also considerably easier and so lessens driver fatigue.

The converter provides an infinitely variable reduction ratio down to 2 to 1 (near stall) which means in practice that the driver does not need to change gear so often as usual.

At the moment the converter is available only with the current nine-speed gearbox, but as higher power to weight ratios become accepted it will probably be possible to eliminate the low-range epicyclic gears from the back of the box, so that a four-speed box with overdrive will be adequate.