WILL HOME-PRODUCED COME INTO ITS OWN?

Page 30

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

ALTHOUGH the writing has been on the wall for a considerable time past, no serious attempt has been made to develop schemes for the use of fuels alternative to petrol and oil. It is not to be concluded that, because a system of fuel rationing has been introduced at the outset, the maximum provision was not made to meet such an emergency as we now have to face, but, at the same time, had the alternativefuel problem been tackled in a manner which its importance certainly justifies, there would, to-day, be many thousands of vehicles running on home-produced fuel.

During the past two or three years we have published in these columns many informative articles on the subject of gas-producers, coal-gas propulsion, and the possibilities of the use of many vegetable products, whilst a complete description of the Sentinel H.S.G., the only vehicle in this country specifically designed and built to use producer gas, was given in our issue dated November 11, 1938.

So far as this machine is concerned it may be that, during the ensuing months, the enterprise shown by its sponsors will be suitably rewarded. It would, indeed, give a tremendous fillip to this side of the industry were the Government to place an order for a number of the type.

As an alternative to a machine designed to use producer gas, there are two possible solutions, both of • which are essentially practical, but which, nevertheless, are not so efficient from the power production standpoint.

The first of these is the use of coal gas and there are two means for employing this fuel. The cheapest and most readily adapted method is to carry the gas in some form of collapsable bag, but as, normally, the gas cannot, in this way, be stored under pressure, the operating radius of a vehicle so equipped is extremely small.

With the experience gained during the 1914-1018 war, and with the obvious possibilities which lie in the use of an improved form of collapsable gas container, it seems practical to suggest that an obvious development lies in the production of a container capable of withstanding a moderate pressure of, say, 30-50 lb. per 54 sq. in. This would, at dace, give a wider sphere of operation with a considerable reduction in the size of the bag to be carried.

The approved method of storing coal gas on a vehicle is by means of bottles made of high-tensile alloy steel. Following intensive and experimental research work, it is now possible to charge such bottles up to a pressure of 5,000 lb. per sq. in. Whilst such a pressure is not used in practice it is useful to know that such bottles have a high factor of safety.

As to the practicability of the system, there are three important factors to consider, and these concern weight, available space for storing the bottles, and the difficulty of replenishing them.

It is conceivable that, in the present circumstances, ay increase in the unladen weight of a vehicle, occaoned by the use of gas bottles or producer-gas ?paratus, will not bring the machine into a higher .xation class, but this is a matter for decision by the ithorities. Given such a concession, the operator is Len concerned only with the fact that the additional eight reduces the pay-load of the machine.

On the average vehicle some difficulty may be experiiced in finding accommodation for the bottles, because, r any reasonable mileage at least four bottles, each iuivalent to approximately one gallon of motor spirit, ould be necessary.

It should be possible to secure a bottle on each side the chassis-frame member, and, perhaps, another Insversely at the rear. As an example of such an arrangement in operation it may be mentioned that the Gas Light and Coke Co. has four of such machines in use—two Thorpycroft 4-tonners and two Albion 7-tormers. All these vehicles carry six bottles each, equivalent to six gallons of motor spirit. In the case of the Albions about 36 miles' running is obtained, and with the Thornycrofts a mileage of approximately 45 is secured on each charge.

Even if the storage problem can be overcome there still remains the difficulty of arranging for replenishment of the bottles. For the system to be universally applicable, it would be necessary for the gas undertakings to establish suitable compression plants right throughout the country.

• Whilst there is little likelihood of any definite step being taken in this direction during the early days of the war, it may be that we shall see developments of the kind should the fuel-supply problem become aggravated.

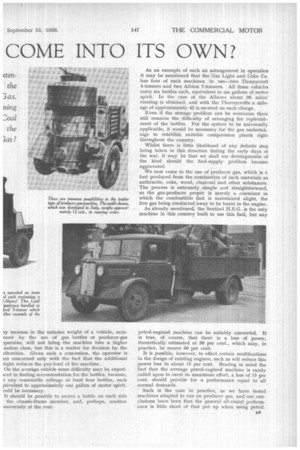

We now come to the use of producer gas, which is a fuel produced from the combustion of such materials as anthracite, coke, wood, charcoal and other substances. The process is extremely simple and straightforward, as the gas-producer proper is merely a container in which the combustible fuel is maintained alight, the free gas being conducted away to be burnt in the engine.

As already mentioned, the Sentinel H.S.G. is the only machine in this country built to use this fuel, but any petrol-engined machine can be suitably converted. It is true, of course, that there is a loss of power, theoretically estimated at 30 per cent., which may, in practice, be nearer 50 per cent.

It is possible, however, to effect certain modifications in the design of existing engines, such as will reduce this power loss to about 15 per cent. Bearing in mind the fact that the average petrol-engined machine is rarely called upon to exert its maximum effort, a loss of 15 per cent, should provide for a performance equal to all normal demands.

Such is the case in practice, as we have tested machines adapted to run on producer gas, and our conclusions have been that the general all-round performance is little short of that put up when using petrol. What modifications are necessary when using coal gas or producer-gas, and how can they be carried out? As is well known, the power output of an engine depends, mainly, upon its volumetric efficiency and compression ratio, and its fuel consumption principally upon the latter.

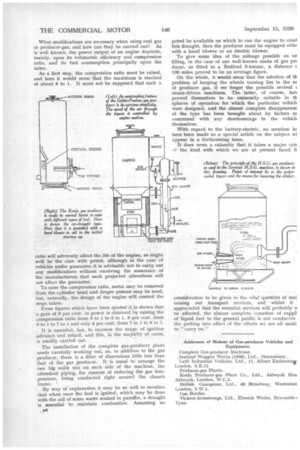

As a first step, the compression ratio must be raised, and here it would seem that the maximum is reached at about 9 to 1. It must not be supposed that such a

ratio will adversely affect the life of the engine, as might well be the case with petrol, although in the case of vehicles under guarantee it is advisable not to carry out any modifications without receiving the assurance of the manufacturers that such projected alterations will not affect the guarantee.

To raise the compression ratio, metal may be removed from the cylinder head and deeper pistons may be used, but, naturally, the design of the engine will control the steps taken.

From figures which have been quoted it is shown that a gain of 8 per cent. in power is obtained by raising the compression ratio from 5 to 1 to 6 to 1, 6 per cent. from 6 to 1 to 7 to 1 and only 4 per cent. from 7 to 1 to 8 to 1.

It is essential, too, to increase the range of ignition advance and retard, and this, in the majority of cases, is readily carried out.

The installation of the complete gas-producer plant needs carefully working out, as, in addition to the gas producer, there is a filter of dimensions little less than that of the gas producer. It is usual to arrange the two big .units one on each side of the machine, the attendant piping, for reasons of reducing the gas temperature, being conducted right around the chassis frame.'

By way of explanation it may be as well to mention that when once the fuel is ignited, which may be done with the aid of some waste soaked in paraffin, a draught is essential to maintain combustion. Assuming no petrol be available on which to run the engine to creat this draught, then the producer must be equipped eithe with a hand blower or an electric blower.

To give some idea of the mileage possible on on filling, in the case of one well-known make of gas prc duces, as fitted to a Bedford 3-tonner, a distance c 130 miles proved to be an average figure.

On the whole, it would seem that the solution of th problem of keeping the wheels turning lies in the 11E of producer gas, if we forget the possible revival steam-driven machines. The latter, of course, hay proved themselves to be eminently suitable in th spheres of operation for which the particular vehich were designed, and the almost complete disappearanc of the type has been brought about by factors nt concerned with any shortcomings in the vehich themselves.

With regard to the battery-electric, no mention ha here been made as a special article on the subject wi appear in a forthcoming issue.

It does seem a calamity that it takes a major cris of the kind with which we are at present faced ft

consideration to be given to the vital question of mai taming our transport services, and whilst it appreciated that the essential services will probably n be affected, the almost complete cessation of suppli of liquid fuel to the general public is not conducive the putting into effect of the efforts we are all maki to "carry on."

Addresses of Makers of Gas-producer Vehicles and Equipment.

Complete Gas-producer Machines.

.Sentinel Waggon Works (1936), Ltd., Shrewsbury. Latil Industrial Vehicles, Ltd., 11, Albert Embankirks London, S.E.11.

Producer-gas Plants.

Koela Producer-gas Plant Co., Ltd., Aklwych Hou Aldwych, London, W.C.2.

British Gazogenes, Ltd., 48 Broadway, Westminst London, S.W.1.

Gas Bottles.

Vickers-Armstrongs, Ltd., Elswick Works, Newcastle-4 Tyne.