BODYBUILDERS

Page 37

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

Solve Operators'

Problems H :YUTLER THE wide variety of goods bodywork shown at Earls Court indicated the diverse needs of operators and demonstrated the ingenuity of bodybuilders in meeting them_ There were platform and sided lorries, boxvans, containers, tippers and selfdischarging vehicles, mobile shops, horseboxes and cattle trucks. Trailers and semi-trailers were also much in evidence.

The exhibition clearly demonstrated the progress that has been made in the use of steel and light alloys for body construction. In many instances, an inspection of the interior of delivery vans and other enclosed types revealed many interesting details of loading equipment, thusshowing how users' experience influences design.

What is a " Pick-up " ?

This year a new term, " pick-up," has been added to vehicle nomenclature; the description is used by Austin, Ford, Standard and Vauxhall. Essentially, a "pick-up" is a small open truck or lorry with fixed sides and hinged tailboard. Mounted behind a standardized. cab, the metal-panelled body has a low floor and flared top boards. The Ford example had an insulated cab, and the body was provided with a tubular superstructure dropping into sockets. also a towing attachment.

The body of the Standard pick-up had lengthwise semovable seats for six persons. Extra seating was also a feature of the Bedford crew utility pick-up. Behind the insulated cab there was a detachable bench-type seat facing the rear and protected by roof and side panels, sliding windows being fitted at the sides and at the back of the cab.

Hitherto, the wood-bodied drop-sided lorry without wheel-arches has been regarded as the type suitable for general-utility work in this country. It will he interesting to see whether a fixed-sided lorry, chiefly of metal construction, with a low floor and wheelarches, will become as popular in this country as undoubtedly it will be for overseas use.

I noted that all-metal standardized cabs, mounted independently, had doors hinged on the forward pillars. Comfort has been much increased and in some instances adjustable seats are provided for drivers. In cabs built integrally with the loading portion, advantages of the sliding door have been fully recognized for the light, van and the large pantechnicon. The door usually slides inside the body, at floor or step level.

A sliding door may give access not only to the cab, but, with an opening in the partition, also to the loading portion. The sliding side doors fitted to the Bedford 30-cwt. three-way-loading van were designed so that they moved outside the body over the wheel-arch enclosure. Hitherto, the presence of a wheel-arch has been regarded as a limiting factor when setting out the travel of a sliding door.

Outsizes in sliding doors were those of the Fordson Thames mobile workshop shown by Garner Motors, Ltd., North Acton Road, London, N.W.10. The vans, which had been built for two leading biscuit manufacturers, each had a pair of rear doors sliding to the right and left respectively.

The roller shutter continues to be favoured for sideand end-loading vans. A new type of rear shutter was shown in a Commer laundry van by Normand, Ltd., Cumberland Avenue, London, N.W.10 It is a flexible door, rather than a roll-up shutter, because the wide wood-faced aluminium slats which are hinged together are upright and, as the door opens, it travels in an arc around the inside corner of the body behind a slatted guard to isolate it from the load. It is claimed that this type of door has high resistance to wear and tear and it ptovides a good surface for display writing.

Another novelty in door mounting was shgwn by Messrs. Reall, Popes Lane, London, W.5. The back and near-side doors of the Dodge Luton van were mounted on pivots at the floor and roof, the centres being set inwards several inches from the shut line, so that, when open, only three-fifths of the door projected, the hinge being concealed when the door was closed.

Luton vans should have a flexible connection between the loading portion

and cab. Sheet rubber or strong fabric material is usually employed for this purpose, for experience has proved that if the cab and body be rigidly connected, the leverage exerted by the sway of a body of maximum height is liable to cause fracture, particularly of the windscreen pillars.

Much ingenuity and careful attention to detail were displayed with regard to the interior equipment of vans. The articulated boxvan designed for carrying Peek Frean's biscuits in tins and shown by the Eagle Engineering Co., Ltd., Warwick, had sliding side and rear doors. The front elevated compartment for empty tins was separated from the lower main portion by a pair of lattice gates.

The main portion of the body was for full tins. Here there were rows of sockets on each side of the body, spaced the Width of a tin apart. By dropping cross-battens into corresponding pairs of near-side and off-side sockets at various levels, a barrier was provided which could be adjusted in relation to its distance from the end of the van, so that the tins were kept in position as the load diminished. The partition lattice gates could be folded against the sides of the body, so that the whole could be used for a bulk load. All dimensions of the body were based on the size of a standard tin. Curved Perspex roof lights provided extra natural lighting.

The 25-30-cwt. van built for J. Lyons and Co., Ltd., with Normand bodywork and shown by Morris-Commercial Cars. Ltd., Adderley Park, Birmingham, had canted and well-guarded side and front shelves of metal, a corrugated metal floor, an inside rear step-well and a Perspex roof light. The side shelves of the laundry van on view on the Karrier stand were of spaced wood slats.

Loading Made Easy

The laundry van with Normand bodywork, mentioned in connection with its flexible door, was fitted with shelves in three sections, which formed a continuous flush surface when all were in use. If the load which had been carried on the rearmost portion of the shelf had been delivered, that shelf could be slid under the other portions.

A baker's van, based on a Karrier Bantam chassis, and shown by the chassis maker, was an up-to-date example of arranging the load on trays and shelves for sideand end-loading. By this means any part of the load was easily accessible.

One of the 15-cwt. standard vans shown by Trojans, Ltd., Purley Way, Croydon, had been modified for the special requirements of the driversalesman of Brooke Bond's tea. There was a waist-high locker, some 14 ins. deep. immediately behind and accessible a4 from the driver's compartment. Below this locker was another of about thi same size lined with metal and reached through a pair of small doors on each side. The main portion of the body behind these upper and lower lockers had a shelf with a section partitioned off for posters. The off-side back door was fitted with a hinged flap which, when supported in a horizontal position, was for use when pasting posters.

As many of the vehicles were for export, cab insulation by means of a packing between the inner and outer panes was a fairly common feature.

In addition, foody-carrying vans, such as the Fordson Thames 5-ton meat vehicle with body work by Wilsdon and Co., Ltd., and the A.E.C. Matador meat van with Bonallack bodywork, were insulated. Another insulated body was the 5-ton container shown by the Duramin Engineering Co., Ltd., Standard Road, Park Royal Road, London, N.W.6.

There has been much development in the manufacture of insulating materials which are not only efficient but light in weight, easy to place in position and resistant to deterioration. Isoflex was used for the Bortallack body and lowdensity Onazote for the Duramin container.

Another insulated van was the Carrimore semi-trailer exhibited on the Vulcan stand. This outfit, for the transport of sausages, was equipped with a 2i-h.p. refrigerator set housed in an insulated compartment, with two 12hour hold-over 'plates on each side.

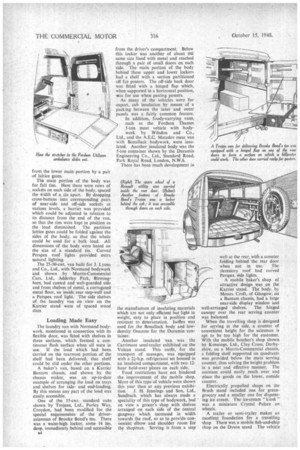

Food restrictions have not hindered the improvement of the mobile shop. More of this type of vehicle were shown this year than at any previous exhibi tion. J. H. Jennings and Son, Ltd., Sandbach, which has always made a speciality of this type of bodywork, had on view a grocer's shop with shelves arranged on each side of the central gangway which increased in width towards the roof, so as to provide convenient elbow and shoulder room for the shopman. Serving is from a step well at the rear, with a counter folding 'behind the rear door when not in use. The clerestory roof had curved Perspex aide tights.

A mobile baker's shop of attractive design was _on the Kayrier stand. The body. by Messrs. Croft, of Glasgow; on a Bantam chassis, had a large near-side display window and well-arranged shelves. The hinged canopy over the rear serving counter was balanced.

When the travelling shop is designed for serving at the side, a counter of tonvenient height for the salesman is apt to be too high for the custorner. With the mobile butcher's shop shown by Kennings, Ltd., Clay Cross, Derbyshire, on a Morris-Commercial chassis, a folding shelf supponted on quadrants was provided below the main serving counter, thus solving the height problem in a neat and effective manner. The assistant could easily reach over and place the goods on the lower, outside counter.

Electrically propelled shops on the Brush stand included one for greengrocery and a smaller one for dispensing ice cream. The ice-cream " kiosk " was a miniature Crystal Palace on wheels.

A trailer or semi-trailer makes. an excellent foundation for a travelling shop There was a mobile fish-and-chip shop on the Dyson stand The vehicle

had a marble slab at the back for the sale of fish. Roller shutters were provided to cover the large, side serving hatches.

Technically, my chief interest was in discovering the advances that have been made in metal body construction. When a hardwpod framework and panels of metal or metal-faced plywood are used, the details of construction do not differ to any great extent. When, however, steel or light alloys are employed, there is a greater divergence of detail. The manufacturer's stock sections may be used, or the body engineer, being in close contact with the problems involved, may design his own sections for certain parts.

At Earls Court two examples of tubular construction were shown by J. H. Sparshatt and Sons (Portsmouth), Ltd., London Road, Portsmouth. One was adapted to a brewer's end-loading lorry and the other to a Luton van. Assembly of vertical and horizontal tubes was facilitated by special cube connectors into which the tubes could be inserted and welded into position_

This method of construction was also employed for the deep cross-bearers of the brewer's lorry, for sides of panelled or skeleton construction, and for doors.

Unless the load be always a light one without hard and sharp corners, a softwood floor soon shows signs of wear. Better-wearing floors are of oak or maple, but for really lengthy service the metal floor will eventually prevail. BonaHack and Sorts, Ltd., Cable Street, London, E.1, has, with its long experience of commercial bodybuilding, given special attention to the metal

floor, and demonstrated its advantages, not only in an insulated meat van and on a triple-drop-sided lorry, both of aluminium-alloy construction, but also on the floor of the stand.

The Dekaloy metal floor is made up of planks of aluminium alloy measuring 8 ins, overall, but interlocking to give an effective width of 7 ins. An inchsquare hardwood wearing strip is inserted over the overlap, through which a woodscrew is passed to secure it to the bearer beneath. This hard wood strip stands in. above the surrounding metal, but is level with the tops of the non-slip bands of the Dekaloy plank.

An practicable duralumin

" plank " floor was by Duramin Engineering Co., Ltd. The planks are close-fitting without wood, and held together and to the bearers by clips The great possibilities of light-alloy construction were shown on the stand of Jensen Motors, Ltd., Wolverhampton, where there was a pantechnicon of 1,632 cubic ft. capacity with an unladen weight of 3 tons 9 cwt. 1 qr. 2 lb. The floor was of corrugated alloy with timber inserts and the interior was panelled with corrugated alloy, similar material being used for the tailboard and back doors.

Discussing the problem of metal versus wood with bodybuilders at the Show, i came to the conclusion that there is no particular bias in favour either of wood or metal, but, with so much bodywork required for export, the concern that is not ready to adopt metal construction may have to refuse an important contract.

Metal Makers Co-operative Those who have adopted metal construction find that expert advice is forthcoming from the manufacturers of steel and light-alloy sections, in order to ensure that the correct specification of metal is supplied and that precautions are taken against corrosion or electrolytic action between dissimilar metals.

Bodybuilders have made marked progress in originality of design and the adoption of more scientific methods of construction and panelling, whether metal or wood be used for framing.

Mention has been made of various items of interior equipment which increase the efficiency of the vehicle as a transport unit. It has not, however, been possible to dear with the many ingenious features of ambulances or the arrangement of the doors and hinged partitions which go to complete the modern horsebox, or the designing of the upper and lower decks and ramps of cattle trucks and containers.