The dry flangeless secured by Locktite, project above the levels

Page 18

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

of the cylinder block with the gasket flame ring located around it and, clamped between head and block, it is protected from the effects of combustion.

Valves faced in stel lite with chromium-plated stems are resistant to heat. The oil two-stage filtration system, providing both main and by-pass filtrations from one cannister, has been derived from the TL12 engine fitted originally to the Marathon and later to Roadtrain. After passing through the filter, oil is cooled before being delivered to the main gallery and on to main and big end bearings, camshaft and timing gears. A separate oil pressure feed to the turbocharger is given priority.

The Fuller nine-speed constant mesh range change RT 609 gearbox is fitted as standard, and is the only option now that Eaton's six-speed overdrive box has been dropped from the sixwheeler specification sheet. The Fuller box gives a wider spread, from 8.56 to 1 to 0.74 to 1, while the rear axle ratio of 6.25 to 1, combining for a maximum road speed of 93 kmh (58 mph), is the middle of three available.

Air-operated brakes are similar to those employed on the heavier eight-legger, though in this case Girling-fixed cam sliding shoes (FCSS) are fitted on the single front steered axle and Albion S cam foundation brakes at the rear.

The rear bogie fitted here with a two-spring taper leaf suspen sion (one each side) has an option of a four-spring design carried on from Bison. The twospring design refined to simplify maintenance is quite different from that currently used at the rear end of the heavier Scammell.

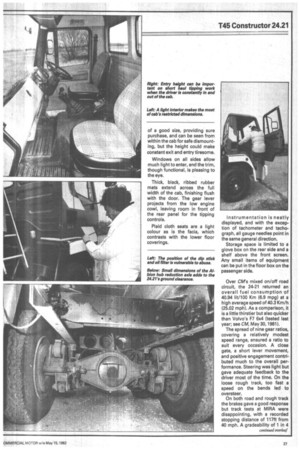

Like the Cruiser, Constructor's C40 cab is less than full width, but over the two days of testing I did not find it restrictive. It is mounted high on the chassis and two staggered steps are needed to gain entry. These are of a good size, providing sure purchase, and can be seen from within the cab for safe dismounting, but the height could make constant exit and entry tiresome.

Windows on all sides allow much light to enter, and the trim, though functional, is pleasing to the eye.

Thick, black, ribbed rubber mats extend across the full width of the cab, finishing flush with the door. The gear lever projects from the low engine cowl, leaving room in front of the rear panel for the tipping controls.

Plaid cloth seats are a light colour as is the facia, which contrasts with the lower floor coverings.

Instrumentation is neatly displayed, and with the exception of tachometer and tachograph, all gauge needles point in the same general direction.

Storage space is limited to a glove box on the rear side and a shelf above the front screen. Any small items of equipment can be put in the floor box on the passenger side.

Over C114's mixed on/off road circuit, the 24-21 returned an overall fuel consumption of 40.94 lit/100 Km (6.9 mpg) at a high average speed of 40.3 Km/h (25.02 mph). As a comparison, it is a little thirstier but also quicker than Volvo's F7 6x4 (tested last year; see CM, May 30, 1981).

The spread of nine gear ratios, covering a relatively modest speed range, ensured a ratio to suit every occasion. A close gate, a short lever movement, and positive engagement contributed much to the overall performance. Steering was light but gave adequate feedback to the driver most of the time. On the loose rough track, too fast a speed on the bends led to oversteer.

On both road and rough track the brakes gave a good response but track tests at MIRA were disappointing, with a recorded stopping distance of 117ft from 40 mph. A gradeability of 1 in 4 will allow the vehicle to climb most severe slopes from rest.

The firmness of the ride was exaggerated by the absence of a driver's suspension seat, and with the cab windows wound down, the dry springs could be heard working hard over the rough. With the cab sealed off from outside noise the journey was very quiet.

A payload of 16 tonnes puts it in the class of other makes of lightweight tippers.

Through the muddy section, with a power to weight ratio of 6.39 kw/tonne (8.76 bhp/ton), careful use of the throttle maintained traction while avoiding any need to bring the third differential into use. And the small dimensions of the hub reduction axles and brake chambers mounted high added to the vehicle's ground clearance.

It took 1 min 30 sec to reach maximum lift with full extension of the triple stage hydraulic ram powered from one of the two pto openings on the gearbox.

The air filter is said to be sited in a clean area, but being positioned so close to the front wheel, it is hard to understand how this can be.

Overall, the Constructor 6 gives an impressive performance. Overall speed, fuel consumption and payload compare well with other vehicles tested by CM. Three good reasons why it holds its place as the biggest selling 24-ton tipper.

White there are improvements that could be made to off-road comfort and the cab height may not be the choice of all, there is little else to find fault with.