A DENNIS DESIGNED FOR

Page 66

Page 67

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

MIES

BY

A. J. P. WILDING A.M.I.MECH.E LOW loading height is a very desirable feature for vehicles on many types of operation.. Not so much on trunk running, which is generally to and from loading banks, but more importantly on local deliveries and on such things as brick transport, where commodities have to be loaded on to the vehicle platform from ground level. Attempts made to solve the problem include such items as dropped platforms with wheelboxes, but this particular design feature can bring its own difficulties. For one thing, the.protrucling wheelboxes make load positioning awkward.

The obvious way of getting low platform height is, of course, to reduce the size of wheels and tyres, but this necessitates smaller brakes, drums and hubs, and then few operators can accept the payload reduction which results. The solution offered by Dennis Bros. Ltd. is the Pax V 6 x 2 Lowloader, which is fitted with 8.25-17 tyres to make a 3-ft. 2.5-in, platform height possible without wheelboxes, and has been designed for a gross weight of 16 tons: this gives a payload capacity of a little more than 11 tons, or more than a maximum-gross four-wheeler.

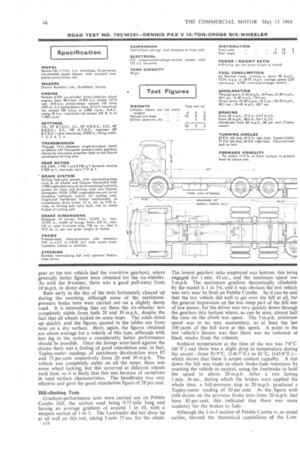

This particular member of the Pax V range has only recently gone into production and was first shown in public at last year's Scottish Motor Show. An 8-tonner from the range was tested by The Commercial Motor last year (April 12 issue) and, like that example, the Lowloader offered by Dennis for test had a Perkins 6.354 engine. Compared with the 8-tonner, the six-wheeler has a relatively fixed specification. The only engine offered besides the 6.354 is the A.E.C. AV 470 7.685-1itre 125-b.h.p. diesel; the Dennis UO five-speed overdrive gearbox is standard and with both engines a 14-in. single-plate clutch is employed. The axle ratio depends on the engine fitted.—

with the Perkins unit it is 7.17 to 1 and with the A.E.C., 614 to I —giving theoretical maximum speeds of 50 m.p.h. with the Perkins and 45.7 m.p.h. with the A.E.C. Maximum gradients climbable in top gear are 137 to I with the Perkins

a31

and 101-4 to 1 with the A.E.C., and the maximum gradient which can be climbed in bottom gear are 5-6 to 1 an 5.12 to 1 respectively, these figures being theoretical also. Four-leaf-spring suspension is used for the rear bogie each spring measuring 42 in. by 3 in. The springs on eacl side are connected through a balance beam, rubber bush ings being used throughout which, of course, eliminates th need for lubrication. The springs are undersIung and, as result, the spring-hanger brackets are fairly large fabrica tions and extend some way below the underside of thl frame side-members. The reason for the springs beinl underslung is to obtain as low a roll centre as possible Another unusual feature of the rear-end design is in thi handbrake system. This operates on the trailing axle wheel brakes as normal, but on the driving axle a transmissiot brake is employed. There is a good reason for this—i, Lpplication had been at the wheel brakes of he driving axle, the angle of the rods or :ables in a conventional layout would be mpractica,ble because of the small dianeter of the brakes and the need to clear he differential housing.

Radial-cord tyres are standard on the .-owIoader. This is necessary because 10 3.25-17, 12-ply textiles would give a total apacity of 0-75 ton less than the maximum )ermissible 16 tons of the model. The -adials give a safety margin of 1 ton on he right side but, even so, the fronts were ;lightly overladen on the model tested.

Two wheelbase dimensions are offered or the Pax V Lowloader-16 ft 11 in. and 14 ft 2 in.-----the latter being the version .ested. In chassis-cab form its kerb weight has 4 to s 0.75 cwt. The test load consisted of iron weights nountec in a tray which took up almost the full 21-ft. 1-in. frame l -igth from behind the cab (on the 16-ft. Il-in.

hh.eelba model this 'dimension is 24 ft. 6.25 in.). This :yen dis ibution of the load produced. 3 tons 13.5 cwt, on he fron axle and 12 tons 12-25.cwt. on the rear bogie. The heights otalled 12 tons exactly and with the driver and .wo pa sengers in the cab the test, vehicle grossed [6 tons 5-75 cwt.

in Economical Vehicle All the tests on the Lowloader were carried out in the 5ui.Idford area and whilst a good figure for fuel consumpion was -obtained and acceleration and braking were of Lverage standard, hill-climbing abilities were poor. Somewhat surprisingly, the fuel-consumption. figure for a 16-mile out-and-return run on the Guildford-Horsham road through Brarnley was about 3 per cent better than the similar run on the test of the Pax V 8-tanner, which had a gross weight almost 4 tons less than the Lowloader. Axle ratios and gearbox types were not the same on the two vehicles, of course, but nevertheless it was not expected that the heavier vehicle would give a better fuel consumption.

To some extent, performance can be said to have been sacrificed for economy, for although the two runs I am comparing were both with the vehicles being driven at up to 40 m.p.h., the average speed for the Lowloader was only 30-75 m.p.h. against 32 m.p.h. for the '8-tanner. And on the test of the latter vehicle, traffic conditions slowed the run, which was not the case in this latest test.

On acceleration tests the times taken on the through-thegear runs were considerably longer than with the 8-tanner, although the figures for the Lowloader were about average for a 16-ton vehicle of its type.

The lower rear-axle ratio of the Lowloader-7-17 to 1 against 6.14--did not have the advantageous effect on these runs as itdid on the direct-drive accelerations (not in top a33 gear as the test vehicle had the overdrive gearbox), where generally better figures were obtained for the six-wheeler. As with the 8-tonner, there was a good pull-away from 10 m.p.h. in direct drive. Rain early in the day of the tests fortunately cleared up during the morning, although some of the maximumpressure brake tests were carried out on a slightly damp road. It is interesting that on these the six-wheeler was completely stable from both 20 and 30 m.p.h., despite the fact that all wheels locked on some stops. The roads dried up quickly and the figures quoted in the tables are from tests on a dry surface. Here, again, the figures obtained are about average for a vehicle of this type, although with less lag in the system a considerably better performance should be possible. Once the linings werehard against the drums there was a feeling of good retardation and, in fact, Tapley-meter readings of maximum deceleration were 85 and 75 per cent respectively from 20 and 30 m.p.h. The vehicle was completely stable on all the stops; there was some wheel locking, but this occurred at different wheels each time, so it is likely that this was because of variations in road surface characteristics. The handbrake was very effective and gave the good retardation figure of 28 per cent.

'Hill-climbing Tests

Gradient-performance tests were carried out on Pebble Combe Hill, the section used being 0.75 mile long and having an average gradient, of around 1 in 10, with a steepest section of 1 -in 5. The Lowloader did not show up at all well on this test, taking 3 min. 37 sec. for the climb.

B34 The lowest gearbox ratio employed was bottom, this being engaged for 1 min. 43 sec., and the minimum speed wal 3 m.p.h. The maximum gradient theoretically climbable by the model is 1 in 5.6, and it was obvious the test vehicle was very near its limit on Pebble Combe. So it can be said that the test vehicle did well to get over the hill at all, but the general impression on the less steep part of the hill wai of low power, for the driver was very quickly down through the gearbox into bottom where, as can be seen, almost hall the time on the climb was spent. The 3 m.p.h. minimum speed was in no way momentary, as at least the lasl 100 yards of the hill were at this speed. A point in the test vehicle's favour was that there was no emission oi black smoke from the exhaust.

Ambient temperature at the time of the test was 7.8°C (46°F) and there was a slight drop in temperature during the ascent—from 81.5°C. (146.7°F.) to 81°C. (145-8°F.)— which shows that there is ample coolant capacity. A run down the hill was made to check brake-fade resistance by coasting the vehicle in neutral, using the footbrake to hold the speed to about 20 m.p.h. After a run lasting 1 min. 36 sec., during which the brakes were applied the whole time, a full-pressure stop at 20 m.p.h. produced a Tapley-meter reading of 50 per cent. As the figure with cold drums on the previous brake tests from 20 m.p.h. had been 85 per cent, this indicated that there was some tendency for the brakes to fade.

Although the 1-in-5 section of Pebble Combe is, as stated earlier, beyond the theoretical capabilities of the Low

loader, it was found possible to start off from a standstill on this slope, although there was some loss of traction from the driving axle. The handbrake held the vehicle comfortably on the gradient, as it did also when facing down the slope. It was not possible to complete a reverse restart when facing down the hill because of wheel slip on the road surface, which was still wet, after the morning's rain, on the part used for these attempts. Reverse ratio is slightly higher than bottom gear, but the main reason for the loss of traction in the second case was undoubtedly the transference of weight from the driving axle when facing down the hill.

Following the road test, Dennis Bros. Ltd. carried out tests with the chassis without weights in an effort to trace the reason for the loss of traction. It was found that by altering the static setting of the rocking beams between the rear springs the driving axleloading was increased in the unladen condition by about 25 percent, This decreases as payload is added, of course, but Dennis reports that on hill-climbing tests using Pebble Combe and other hills under varying payload conditions from unladen to a gross weight of 16 tons and with the road surface similar to that for my test, the revised geometry of the rocking beam had eliminated any tendency for the driving axle to lose traction. Following the concern's own tests, Dennis introduced the modification into production immediately and have taken restrictive action on vehicles already delivered.

Lack of power is the main criticism I have of the test vehicle, others being excessive brake-pedal travel before the brakes are applied and a

certain amount of vagueness in the steering. The degree of brake-pedal travel is possibly linked to the use of the twin Hydrovacs, and whilst it would cause no trouble to a driver fully used to the vehicle, it is rather frightening when first experienced, the pedal going down and down until the point at which the brakes are on is reached. The model tested had power-assisted steering which was very light, but there was little feeling of castor action and it was difficult to keep the vehicle to a straight path. The power assistance is an option, of course, and I would have liked to have tried the vehicle with less "assistance ", or in standard form.

Consumption Main Consideration To some extent it is unfair to criticize the Lowloader for lack of power, as the vehicle is basically intended to be used on delivery work and for this reason will be operating for much of its time with part-loads. Some operators may consider the very good fuel consumption outweighs the lack of power but, as tested with a full load, it was certainly embarrassing to be continually leading a stream of cars, as was the case when I drove the vehicle towards the end of the day. The slightest "pimple " brought the speed down sharply and often required a downward gear change, and on some relatively short hills the speed frequently fell to around 10 or 15 m.p.h. I think I would opt for the A.E.C. AV 470 engine on the grounds of greater power, particularly if the vehicle was to be used in very hilly conditions. It was suggested to the Dennis engineers that the higher-rated version of the Perkins 6.354 would be a better proposition than the standard version, but it was said that this would be no real advantage as the important thing is the torque produced, this being the same but at a higher speed.

The Dennis gearbox is a very good unit, with a very easy change and well-spaced ratios. The gear speeds on the test vehicle were 5 m.p.h., 12.5 m.p.h., 24 m.p.h., 42 m.p.h. and about 52.5 m.p.h. The suspension was also very good, giving a comfortable ride and producing little roll.

In general design, the cab is good—it is the usual reinforced plastics model standard on Pax V variants and has a good-sized windscreen and all-round vision. The driver's and passengers' seats are comfortable, but when a second passenger is carried, one man sits more or less on the engine cowl and it is difficult in this position to place the legs comfortably. Access to the cab is excellent and the general standard of interior finish is high. This was remarked on in the 8-tormer test report and since then ash trays and a cigarette lighter have been added to the specification. Controls are well placed to make them easy to operate and the instruments are also well arranged. The list price of the Dennis Pax V Lowloader as tested is £2,490, which includes £260 for the cab. Specification of the A.E.C. AV 470 engine adds £360. Power steering costs £87, heater and demister unit £16, and many other optional extras are avaPable.