AIDS TO SOLVING FORD PROBLEMS.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, which will Appeal to the Owner, Driver, and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they are employed for commercial purposes, which commenced recently, we propose to deal with the subject from every viewpoint, so that the advice given will appeal to the owner, driver, maintenance engineer, or mechanic. Valuable sources of information will be tapped for this purpose, and it should be understood that the information given will all be derived from those with a practical and intimate knowledge of

the subject. .

We shall welcome for inclusion amongst the hints those which have proved of value to individual users, and will make suitable remuneration for any published, What we desire are the results of practice, and not so-called improvements, . which are but theoretical.

29.—Setting Valve Tappets.

On the setting of Ford valve tappets there are diverse opinions. The makers recommend 25,000ths clearance for the exhaust valve and 20,000ths for the inlet, but at the repair works of Wallace-Harmer Motors, Ltd., the bestresults have been obtained with 18.000ths clearance for the exhaust and 15,000ths for the inlet.

30.—Noisy Timing Gears and the Causes.

The Ford timing gear is sometimes noisy. This is caused by the crankshaft being bedded too low or too high. If the former, the teeth are drawn partially out of mesh and the noise developed is a -type of knock. If the bedding is too high the teeth mesh too deeply, causing a distinct roar when the engine is running at a fair speed.

31.—How to Extract Rear-axle Roller-bearing Sleeves on the Ton Ford.

One of our contributors was recently placed under the necessity of removing the rear-axle roller-bearing sleeves of his Ford ton truck.

. This, as it happens, is a somewhat difficult task, as the sleeves, which are split diagonally, are each provided with a small stop which springs into a hole drilled in the axle tube.

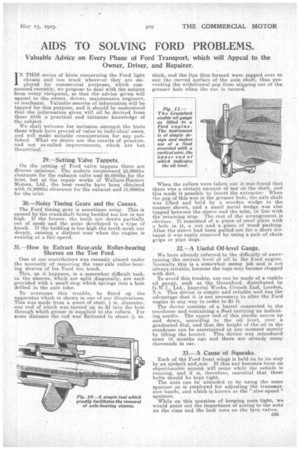

To overcome this trouble, he fitted up the apparatus which is shown in one of our illustrations. This was made from a piece of steel, in. diameter, one end of which was turned up to fit into the hole through which grease is supplied to the rollers. For some distance the rod was flattened to about in. thick, and the lips thus formed were tapped over to suit the curved surface of the axle shaft, thus preventing the withdrawal peg from slipping out of the greaser hole when the nut is turned.

When the rollers were taken out itwas found that there was a certain amount of sag on the shaft, and this made it possible to insert the extractor: When the peg of this was in the greaser hole, the axle shaft was lifted and held by a wooden wedge in the manner. shown, and a small metal wedge was also tapped between the sleeve and the tube, in line with the-retaining stop. The rest of the arrangement is obvious. It consisted of a piece of •steel plate with a hole in it, a nut and a piece of wood packing. After the sleeve had been pulled out for a short distance it. was easily removed by using a pair of chain grips or pipe dogs.

32.—A Useful Oil-level Gauge.

We have already referred to the difficulty of ascertaining the correct level of oil in the Ford engine_ Normally this is a somewhat messy job and is not always reliable, because the taps may become clogged with dirt.

To avoid this trouble, use can be Made .of a visible oil gauge, such as the Greenford, distributed by G.W.I., Ltd., Imperial Works, Crouch End, London, N.s. This device is simple and reliable and has the advantage that it is not necessary to alter the Ford engine in any way in order to fit it. The device consists of a barrel connected to the crankcase and containing a float carrying an indicating needle. The upper end of this needle moves up and down,_ according to the oil. level, over a graduated dial, and thus the height of the oil in the crankcase can be ascertained at any -moment merely by lifting the bonnet. This device was introduced some IS months ago and there are already many thousands in use.

33.—A Cause of Squeaks.

Each of the' Ford front wings is held on to its stay by an eyebolt and,nut. If this nut becomes loose an objectionable squeak will occur while the vehicle is running, and it is, therefore, essential that these boltsshould be kept tight. The nuts ca-n be attended to by using the same spanner as is employed for adjusting the transmission bands, and which is knowil as the " slow-speed " spanner. While on this question of •keeping nuts tight, we would point out the importance of seeing to the nuts on the rims and the lock nuts on the tyre valves.