A TWO-PURPOSE LORRY.

Page 8

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

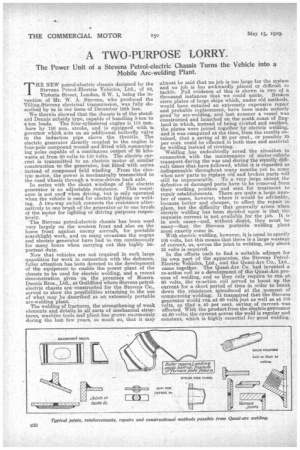

The Power Unit of a Stevens Petrol-electric Chassis Turns the Vehicle into a Mobile Arc-welding Plant.

THE NEW petrol-electric chassis designed by the Stevens Petrol-Electric Vehicles, Ltd., of 82,

Victoria Street, London, S.W. 1, being the invention of Mr. W. A. Stevens, who produced the Tilling-Stevens electrical transmission, was, fully described by us in our issue of December ll)th last.

We therein showed that the chassis is of the standard Dennis subsidy type, capable of handling 3-ton to 4-ton loads. The four-cylindered engine is 115 mm.

Bore by 150 mm. stroke, and is equipped with .a.. governor which acts on an additional butterfly valve

in the induction pipe above the threttle. The electric generator directly coupled to the engine is four-pole compound wound and fitted with commutat

ing poles capable of a continuous output of 25 kilo

watts at from. 80 volts to 110 volts. The electric current is transmitted to an electric motor of similar construction to the generator, but fitted with series instead of compound field winding From the electric motor, the power is mechanically transmitted to the road wheels through a, worm-driven back axle.

In series with the shunt windings of the electric generator is an adjustable resistance. This resist ance is not use when driving, but is only operated when the vehicle is used for electric lighting or welding. A two-way switch connects the resistance alter natively to one brush of the generator or to one brush of the motor for lighting or driving purposes respectively. '

The Stevens petrol-electric chassis has been used very largely on the western front and also on the

home front against enemy aircraft) for portable searchlight work, and on many occasions the engine and electric generator have had to run continuously for many hours when carrying out this highly important duty.

Now that vehicles are not required in such large quantities for work in connection with the defences, fuller attention has been devoted to the development of the equipment to enable the power plant of the chassis to be used for electric welding, and a recent demonstration given on the premises of Messrs. Dennis Bros., Ltd., at Guildford where Stevens petrolelectric chassis are constructed for the Stevens Co., served to show the possibilities attaching to the use of what may be described as an extremely portable arc-welding plant. The welding of fractures, the strengthening of weak elements and details in all sorts of mechanical struc tures, machine tools and plant has grown enormoUsly during the last few years, so much so, that it may almost be said that no job is too large for the system and no job is Coo awkwardly placed or difficult to tackle. Full evidence of this is shown in, two of a thousand instances that we could quote. Broken stern plates of large ships which, under old methods, would have entailed an extremely expensive repair and probable replacement, have been made entirely good by arc-welding, and last summer a vessel was constructed and launched on the south coast of England in which, instead of being riveted and caulked, the plates were joined together by electric welding, and it was computed at the time, from the results obtained, that a saving of 20 per cent., or possibly 25 per cent. could be effected in both time and material by welding instead of riveting. Welding has undoubtedly saved the situation in connection with the maintenance of motor-vehicle transport during the war and during the equally difficult times that have followed, whilst it is regarded as indispensable throughout many months yet to come when new parts to replace old and broken parts will still be unprocurable. To a very large extent the defective or damaged parts have to be removed from their working position and sent for treatment to repair establishments. There are quite a large number of cases, however, where it would be advisable, because better and cheaper, to effect the repair in place, but the difficulty that generally arises when electric welding has been decided upon is that the requisite current is not available for the job. It is in such cases—and, without doubt, they must be many—that the Stevens portable welding plant must exactly come in. With electric welding, however, it is usual to specify 105 volts, but this means that there is a large wastage of current, as, 'across the joint in welding, only about 35 volts is required.

In the efforts each to find a suitable adjunct for its own part of the apparatus, the Stevens PetrolElectric Vehicles, Ltd., and the Quasi-Arc 'Co., Ltd., came together. The Quasi-Arc Co_ had invented a re-action coil as a development of the Quasi-Arc proTess of welding, and as they only require to run at 60 volts, the re-action coil served to boost up the current for a short period of time in, order to break down the , resistance, introduced at the . moment of commencingwelding. It transpired that the Stevens generator would run at 80 volts just as well as at 105 volts, so that a, 40 per cent, saving of current was effected. With the product from the eltric generator at.60 volts, the current across the weld is regular and constant, which is highly essential for good welding. In the course of the demonstration it was shown that the welding agency of the electric arc was very highly localized, bringing about autogenous union, the fusion starting immediately the arc was struck. By means of the company's patented electrodes—the electrode being coyered by an asbestos preparation— the surface of the weld as it is formed becomes covered over by a slag from the covering material of the electrode and oxidization is entirely prevented; this slag covering is afterwards readily chipped or brushed off, leaving a bright and clean metallic surface. A number of joints were made in the course of the demonstration, whilst other extremely interesting operations consisted of depositing a small mass of metal on a. steel shaft sufficient to be formed into a, substantial feather. A large rear axle bracket casting of a 4-ton lorry was produced, where the slot in the spring pad had been cut one-eighth of an inch too wide, according to modern methods of accurate fitting, the casting was spoiled, but by the new process

a quarter of an inch of metal was added, thus bringing the casting back into use again.

We see many applications to motor work of this useful property attaching to the combination of the Stevens Petrol-Electric chassis and the Quasi-Arc welding process and control, and we can quite imagine a couple of men with the necessary small amount of capital acquiring a lorry with a duplicate. welding plant (for it was clearly shown that two and even three jobs could be carried out simultaneously from the one power plant)going from place to place throughout the country carrying out repairs in situ, and the operations need not be confined purely to welding. To give an example : the electric light station of private house recently broke down and the batteries would have commenced .to deteriorate before the dynamo could have been repaired. A Stevens

• petrol-electric chassis was driven to the light station, connected up to the batteries, and the batteries were charged up, the job being done in four hours.