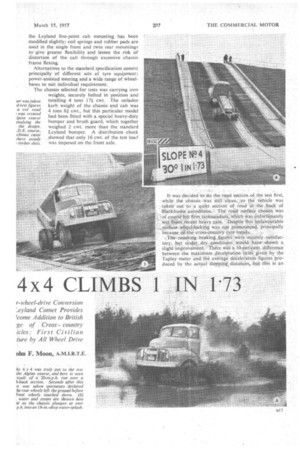

NEW 5-T( 4 x 4 CLIMBS I IN 1'73

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

r-wheel-drive Conversion lei/land Comet Provides 'come Addition to .British ke of Cross-country ides: First Civilian lure by All Wheel Drive

ohn F. Moon, A.14.1.R.T.E. FEW wheeled vehicles have been known to climb the 1 in 1.73 test gradient at the Ministry of Supply's F.V.R.D.E. testing ground at Chobham. One that has done so is a new 5-ton 4 x 4 vehicle, based on a well-known Leyland design and adapted by a little

known but well-established company.

In export markets particularly, there is -a dearth of reasonably priced British multi-wheel-drive vehicles with a payload capacity in the 5-7-tot range. This market has large possibilities, particularly in development areas of the British Commonwealth. Operators in such regions will welcome the introduction of the .Leyland-A.W.D. 5-tanner, particularly as it is backed by the world-wide Leyland service organization.

The new chassis, although strictly a "conversion," is worthy of a better name. Its complete° design has been based on the original Leyland Comet semi-forwardcontrol chassis. All Wheel Drive, Ltd.,_have.made slight structural modificatiOns to .suit _their .own design, but the vehicle bears the hallmark of an all-Leyland product.

• The engine (except'for a modified sump shape). main gearbox, suspension, steering, brakes and rear axle are standard Leyland units, whilst the chassis frame has been modified only in respect of the re-location of various crass-members, the use of high-tensile bolts rather than rivets and of heavier spring-anchor brackets.

Standard Leyland spiral-bevel final-drive and differential gears are incorporated in the front axle, providing interchangeability with the rear-axle geating, whilst thecentre section of the front axle isalso the normal Leyland casting. This axle has Tracta constant-velocity universal joints, which • are totally enclosed and run in

oil-baths jirovided by theaxle tubes and the steering

knuckles.

The, auxiliary gearbox is a completely All Wheel Drive . design. Single helical gears are used and the box provides ratios of 2.105 to 1 and 1 to 1. Front-wheel drive can be engaged independently of the auxiliary-box ratio, bin an interlock ensures that .low ratio cannot be used unless the front-wheel-drive is _engaged. .

There is provision for a second ,output flange at_the rear of the box for use when it is _desired to drive the bogie -axles of a six-wheeler theough separate propeller shafts,

Lubrication of this unit has received Close attention and pressed-steel troughs are provided at all the bearings a I to direct the flow of oil where it is most required. A magnetic drain plug ensures that stray particles of metal do not circulate in the box with the oil.

The efficiency of the lubrication system of this gearbox was emphasized during an hour's hard running on the Ministry of Supply. Alpine course at Bagshot Heath_ At the end of this test the oil temperature in the auxiliary box was only 88° F.

Provision is made for the use of a full-torque power All Wheel Drive, Ltd., emphasize that the vehicle has not been produced to meet specific military combat specifications, and that the standard Leyland 9-in. frame has been used. To allow for severe cab flexing when running on rough ground the Leyland five-point cab mounting has been modified slightly; coil springs and rubber pads are used in the single front and twin rear mountings to give greater flexibility and lessen the risk of distortion of the cab through excessive chassis frame flexing.

Alternatives to the standard specification consist principally of different sets of tyre equipment; power-assisted steering and a wide range of wheelbases to suit individual requirement.

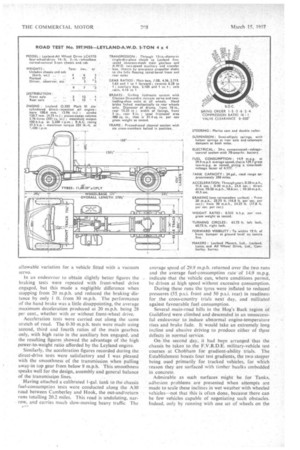

The chassis selected for tests was carrying iron weights, securely bolted in position and ler was taken totalling 4 tons 174 cwt. The unladen d-test figures kerb weight of the chassis and cab was a wet road 4 tons 64 cwt., but this particular model was created lpine course had been fitted with a special heavy-duty I studying the bumper and brush guard, which together the design. weighed 2 cwt. more than the standard .D.E. course, Leyland bumper. A distribution check ,here steady showed that only 16 cwt. of the test load ' ?timber slats. was imposed on the front axle. It-was decided to do the road section of the test first, while the -chassis was still clean,, so the vehicle was taken out to a quiet ,section of road at the back of Rlackblishe aerodrimierThe road surface chosen was of coarse but firm.tarmacadarn, which Was unfortunately wet from recent heavy rain. Despite this 'unfavourable , surface wheel-locking was not pronounced, principally because of the cross-country tyre treads.

The resulting braking figures were entirely satisfactory, but under dry, conditions would have shown a slight improvement.There was a 10-per-cent. difference between the maximum deceleration rates given by the Tapley meter 'and the average deceleration figures produced by the actual stopping. distances, but this is an

allowable variation for a vehicle fitted with a vacuum servo.

In an endeavour to obtain slightly better figures the braking tests were repeated with front-wheel drive engaged, but this made a negligible difference when stopping from 20 m.p.h. and reduced the braking-distance by only I ft. from 30 m.p.h. The performance of the hand brake was a little disappointing, the average maximum deceleration produced at 20 m.p.h. being 28 per cent., whether with or without front-wheel drive.

Acceleration tests were carried out along the same stretch of road. The 0-30 m.p.h. tests were made using second, third and fourth ratios of the main gearbox only, with high ratio in the auxiliary box engaged, and the resulting figures showed the advantage of the high power-to-weight ratio afforded by the Leyland engine.

Similarly, the acceleration figures recorded during the direct-drive tests were satisfactory and I was pleased with the smoothness of the transmission when pulling away.in top gear from below 9 m.p.h. This smoothness speaks well for the design, assembly and general balance of the transmission lines.

Having attached a calibrated 1-gal. tank to the chassis fuel-consumption tests were conducted along the A30 road between Camberley and Hook, the out-andlreturn runs totalling 20.2 miles. This road is undulating, nar row, and carries much slow-moving heavy traffic The p.

average speed of 29.9 m.p.h. returned over the two runs arid the average fuel-consumption rate-of 14.9 m.p.g. indicate that the vehicle can, where conditions permit, be driven at high speed without excessive consumption.

During these runs the tyres were inflated to reduced pressures (55 p.s.i. front and 50 p-s.i. rear) in readiness for the cross-country trials next day, and militated against favourable fuel consumption.

Several main-road hills in the Hog's Back region of Guildford were climbed and descended in an unsuccessful endeavour to induce abnormal engine-temperature rises and brake fade. It would take an extremely long incline and abusive driving to produce either of these tiefect in normal service.

On the second day, it had been arranged that the chassis be taken to the F.V.R.D.Er. military-vehicle testcourses at Chobham for gradient-ability trials. The Establishment boasts four test gradients, the two steeper being used primarily for tracked vehicles, for which reason they are surfaced with timber baulks embedded in concrete.

Admirable as such surfaces might be for Tanks, adhesion problems are presented when attempts are made to scale these inclines in wet weather with wheeled vehicles--not that this is often done, because there can be few vehicles capable of negotiating such obstacles. Indeed, only by running with one set of wheels on the concrete edging strip of the 1 in 1.73 slope was it possible to achieve sufficient adhesion to climb this gradient.

The ascent of this steepest slope was made with low ratio in both gearboxes and front-wheel drive engaged, and full throttle was necessary. Because of the slippery surface, occasional wheel-slip occurred, but generally progress up this 30' incline was awe-inspiring and possibly unique in the history of British vehicle construction.

The less steep slopes came as an anticlimax, but provided an opportunity to assess the power of the hand brake and the ability of the engine to pull away from a standstill. The second steepest slope is of 1 in 2 severity and has a timber and concrete surface, the slats of which had been badly chewed up by Tanks, with the result that pieces of wood were flung from below the wheels of the Leyland when ascending the gradient.

Half-way up this incline the chassis was stopped and held satisfactorily on the hand brake, although it had to be applied initially with assistance from the foot brake. A smooth re-start was then Made and surprised even the designer of the vehicle. At no time during this or any other of the gradient tests was smoke emitted from the exhaust pipe.

Stopped on 1 in .2 Grade

. The chassis was turned round at the top and headed down the 1 in 2 incline and once again was slopped. This time the hand brake had to be pulled back off the ratchet to hold the chassis. This was the only weak spot in the design, and a longer lever with a better ratchet system could profitably be used.

Stop-start tests in forward and reverse were conducted on the 1 in 3 and 1 in 4 concrete slopes. In the caseof the I in 3 incline, second gear in the main box, combined with low ratio at the auxiliary, was sufficient to take the vehicle over the top, whilst the 1 in 4 slope was climbed in bottom gear in the main gearbox with high auxiliary ratio engaged When reversing up this incline it was necessary to engage low auxiliary ratio because of the difference between the first and reverse ratios of the main gearbox.

From the test slopes the 4 x 4 was driven straight out to the Alpine course at Bagshot Heath. Before starting the circuits, temperature checks were made and after a hour comparative checks were taken. It will be seen from the accompanying table that all the temperatures were lower.

The drop in coolant temperature can be explained by the amount of low-gear running at high engine speeds, which resulted in the 'high fan speed causing over-cooling. The relatively low ambient temperature (50° F.), the high wind, and the amount of running done through water would partly account for the low temperatures of the lubricants in the transmission lines, but undoubtedly much credit must be given to the efficiency of the lubrication systems.

As the differences in temperature show, high-speed running on the road is far more likely to cause a rise in lubricant temperature than lowspeed running off the road.

Throughout the tests on the Alpine course the performance of the Leyland was above reproach, except that the auxiliary gearbox jumped out of mesh on two occasions-during extremes of chassis flexing.

Traction was good over all surfaces,. wet and dry, hard and soft, and little performance appeared to be lost by having twin tyres on the rear axle. At no time did steering become uncontrollable, whatever the surface or speed, showing that an excellent combination of front suspension and, steering geometry exists.

Power Steering Offered

Power steering, which is offered, would be of little advantage for cross-country purposes and would be a consideration only when manceuvring at low speed on hard ground, when the steering is inclined to be on the heavy side.

The robustness of the chassis was pat to, the test many times, particularly over, the witching-wave section, where spectators declared that all wheels left the ground on several occasions. I scarcely noticed such acrobatics when driving, such is the stability and control afforded by the design.

I was entirely satisfied with the performance of this new design on and off the road. I feel sure that it will find -a large market wherever the going is hard. All _Wheel Drive, Ltd., are to market the chassis with the approval of Leyland Motors, Ltd.

Maintenance should be no more difficult than that of the ordinary Leyland Comet chassis, particularly as great use has been made of standard Leyland components in the nonstandard sub-assemblies. . All Wheel Drive, Ltd., are to be congratulated on this, their first venture into the civilian market, with a design which is thoroughly practicable, potentially. Tong-lived and extremely welt-made.