40-ton Bottom Dumper Works on Private Motorway

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

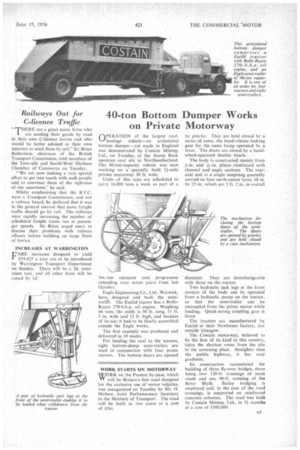

OPERATION of the largest coalhaulage vehicle—an articulated bottom dumper—yet made in England was demonstrated by Costain Mining, Ltd., on Tuesday, at the Acorn Bank opencast coal site in Northumberland. The 40-ton-capacity vehicle was seen working on a specialty built 11-mile private motorway 30 ft. wide.

Units of this type are scheduled to carry 16,000 tuns a week as part of a 5m.-ton opencast coal programme extending over, seven years from last October.

Eagle Engineering Co., Ltd., Warwick, have designed and built the semitrail'''. The Euclid tractor has a RollsRoyce 270-b.h.p. oil engine. Weighing 66 tons, the outfit is 50 ft, long, 11 ft. 3 in. wide and 12 ft. high, and because of its size it had to be finally assembled outside the Eagle works.

The first example was produced and delivered in 19 weeks.

For hauling the coal to the screens, eight bottom-dump semi-trailers are used in conjunction with four prime movers. The bottom doors are opened

by gravity. They are held closed by a series of cams, the hand-release locking gear for the cams being operated by a lever. The doors are closed by a handwheel-operated double winch.

The body is constructed mainly from 1-in. and *-in. plates reinforced with channel and angle sections. The rearaxle unit is a single unsprung assembly carried on four earth-mover tyres, 18 in. by 25 in., which are 5 ft. 2 in. in overall diameter. They are interchangeable with those on the tractor.

Two hydraulic jack legs at the front corners of the body can be operated from a hydraulic pump on the tractor. so that the semi-trailer can be uncoupled from the prime mover while loading. Quick-acting coupling gear is fitted.

The tractors arc manufactured by Euclid at their Newhouse factory, just outside Glasgow.

The Costain motorway, believed to be the first of its kind in this country, takes the shortest route from the site to the screening plant. Straighter than the public highway, it has easy gradients.

Its construction necessitated the building of three fly-over bridges, there being two 120-ft. crossings of main roads and one 90-ft. crossing of the River Blyth. Bailey bridging is employed and, in the case of the road crossings, is supported on reinforced concrete columns. The road was built by Costain Mining, I.td.. in 31 months at a cost of £100,000,