Danish Crankshaft Grinder

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

To Be Made in This Country

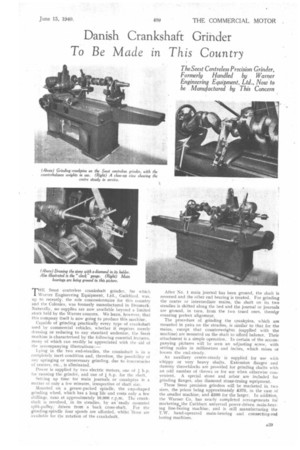

TheSeest Centreless Precision Grinder, Formerly Handled by Warner Engineering Equipment, Ltd., Now to be Manufactured by This Concern

THE Seest centreless crankshaft grinder, for which Warner Engineering Equipment, Ltd., Guildford. was, up to recently, the sole concessionnaire for this cotintry and the Colonies, was formerly manufactured in Denmark. Naturally, no supplies are now, available beyond a limited stock held by the Warner concern. We learn, however, that this company itself is now going to produce this machine.

Capable of grinding practically every type of crankshaft used by commercial vehicles, whether it requires merely dressing or reducing to any standard undersize, the Seest machine is characterized by the following essential features, many of which can readily be appreciated with the aid of the accompanying illustrations:—

Lying in the two end-steadies, the crankshaft is in a completely inert condition and, therefore, the possibility of any springing or unnecessary grinding, due to inaccuracies of centres, etc., is eliminated.

Power is supplied by two electric motors, one of h.p. for running the grinder, and one of h.p. for the shaft.

Setting up time for main journals or crankpins is a matter of only a few minutes, irrespective of shaft size.

Mounted on a grease-packed spindle, the cup-shaped grinding wheel, which has a long life and costs only a few shillings, runs at approximately 10,000 r.p.m. The crankshaft is revolved, in its steadies, by an 'easily mounted split-pulley; driven from a back cross-shaft. For the grinding-spindle four speeds are afforded, whilst ihree are available for the rotation of the crankshaft. After No. 1 main journal has been ground, the shaft is reversed and the other end bearing is treated. For grinding the centre or intermediate mains, the shaft on its two steadies is shifted along the bed and the journal or journals are ground, in turn, from the two trued ones, thereto, ensuring perfect alignment.

The procedure of grinding the crankpins, which are mounted in pairs on the steadies, is similar to that for the mains, except that counterweights (supplied with the machine) are mounted on the shaft to afford balance. Their attachment is a simple operation. In certain of the accompanying pictures will be seen an adjusting screw, with setting scales in millimetres and inches, which raises or lowers the end-steady.

An auxiliary centre-steady is supplied for use with whippy or very heavy shafts. Extension flanges and dummy throwblocks are provided for grinding shafts with an odd number of throws or for usô when otherwise convenient. A special stone and arbor are included for grinding flanges, also diamond stone-truing equipment.

These Seest precision grinders will be marketed in two sizes, the prices being approximately £375, in the case of the smaller machine, and £500 for the larger. In addition. the Warner Co. has nearly completed arrangements for marketingothe Cuthbert uniyersal power-driven main-hearing line-boring machine, and is still manufacturing the T.W. hand-operated main-bearing and connecting-rod boring machines.