• A SIX-CYLINDER L.G.O.C. COACH.

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

Progress towards Speed, Luxury and Safety in Coach Travelling is Continuous. A Notable Advance in Design is Here Indicated.

A N entirely new coach has been on the stocks for the London General Omnibus Co., Ltd., for some time, and it has row been manufactured by the Associated Equipment Co., ,•Ltd., and the bodybuilding department of the Chiswick overhaul factory, and, of course, will be available for other coach-operating concerns.

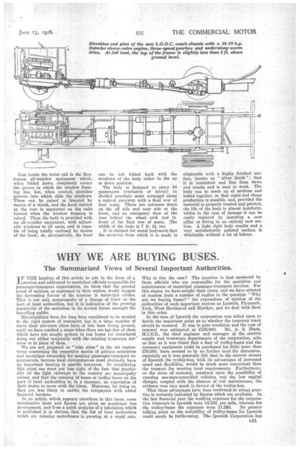

Its main features are its low platform line and the extreme comfort arising from the type of power unit and transmission employed and from the design of the coach body. With a raked centre line for the engine and transmission the frame is cranked downwards behind the engine, and presents a horizontal line through to the rear except at the wheel arch.

An extremely interesting departure is represented by the fact that a sixcylinder Daimler-Knight sleeve-valve engine is employed. The cylinder bore is 61.5 ram and the piston stroke 114 mm., and at 1,000 r.p.m. the engine is rated as of 30 b.h.p.

The carburetter is disposed on the off side, and the magneto and dynamo are driven in tandem and are mounted on platforms on the near side of the engine; i he fan is driven by a belt and the water pump is driven from the same shaft that drives the magneto and generator. The power is transmitted through a single-plate clutch and a clutch shaft universally jointed at each end to a three-speed gearbox, which is three-point suspended upon two tubular cross-members of the frame. This gearbox is of the chain type, as developed for the B-type bus. The gear ratios are :—Top gear, direct; second speed, 1.65 to 1; first speed, 3.39 to 1; reverse, 3.56 to 1. The other ratios are as follow :—Worm ratio, 2.09 to 1; internal final drive, 4.42 to 1. With these ratios and at an engine speed of 1,000 r.p.m., the speeds attained are as follow :—On top gear, 11.8 m.p.11.•' on second speed, 7.16 m.p.h.; on first speed, 3.48 m.p.h.; whilst, on reverse, the speed is 3.31 m.p.h.

From the gearbox the power is transmitted by a divided propeller shaft with a bearing a little bit short of the midway length; it is universally jointed behind the gearbox and behind the midway bearing, and also in front of the wormshaft bearing. The worm is of the undertype order, and the final drive is by internal gear, such as is employed on the N.S. type of omnibus.

The brake system is the same as that of the N.& bus chassis, all the brakes operating on the drums on the rear wheels.

The chassis is mounted on 36-in. by 6-in, pneumatic tyres, twins on the rear wheels.

Long flexible springs are employed at the front and rear, and the driver's position is placed beside the engine.

The wheelbase of the chassis is 15 ft. 8 ins, and the height of the chassis loaded (from the ground to the top ot the frame) is 1 ft. 111 ins. It is interesting to note that the centre line of the engine and transmission is nearly 3 ins, to the left of the centre line of the chassis. This gives the necessary space within the frame for the steering gear and control pedals.

The petrol tank, which has a capacity of 30 gallons, is mounted in the frame immediately behind the rear axle,, whilst to its rear is a carrier for the spare wheel and tyre.

The body is of an entirely new type, in which metal alone is employed, the reasons being the scarcity at present of well-seasoned timber and the difficulty of getting material of good grain with no hidden flaws or knots which, as all woodworkers know, are apt to occur at vital points. It is difficult, again, to prevent the ingress of water and the intrusion of damp, which cause variations in dimensions and the opening up of joints, besides setting up rot in the timber. Also, with a wooden body it is not always easy satisfactorily to repair framework and pillars where rot has occurred.

A considerable amount of experimenting has been undertaken at the instigation of the London General Omnibus Co., and a satisfactory design of allmetal body has now been evolved.

The main framing, which carries the weight and connects the body proper to the chassis frame, is composed of Tiron suitably pressed together and divided into sections so as to support

and carry the floor, which is again divided into suitable squares and rectangles to permit of easy manufacture and assembly. The floor is made of light-section corrugated sheets of great rigidity, strips of fabric being etn-• ployed to prevent squeaks and rattles, and the whole floor being fastened down to the main frame by small Ubolts and clips.

The main members of the T-iron framing extend the full width of the body, and by means of aluminium castings are joined to the main vertical side pillars, which are formed of sheet material folded on a former to give the necessary curves and sweeps. A flitch plate runs the full length of the pillar to strengthen it and to form a convenient means to fasten the main pillar to the T-iron of the body framing.

The panels are attached to the main pillars by being folded round and gripping the outer edge of the U section, thus doing away with all welding or other means of jointing, the joint thus formed, however, being covered by small beading run vertically down each panel.

Connecting the main pillars and running right round the body horizontally, so as to form a rigid structure, are hollow-section• rails with flanges to bolt between the main pilltas.

Just inside the waist rail is the Beatonson all-weather equipment which, when folded down, completely covers the groove in which the window framing lies, but, when erected, provides grooves into which slide the windows. These can be raised or lowered by means of a winch, and the hood carried at the rear is supported on the rails formed when the window framing is raised. Thus, the body is provided with an all-weather equipment, with adjustable windows to all seats, and is capable of beinsb totally enclosed by means of the hood; or, alternatively, the hood

can be left folded back with the windows of the body either in the up or down position.

The body is designed to carry 24 passengers (exclusive of driver) in divided armchair seats arranged along a central gangway with a final row of four seats. There are entrance doors on the off side and near side at the front, and an emergency door at the rear behind the wheel arch and in front of the final row of seats. The width of the body is 7 ft. 51 ins.

It is claimed for metal bodywork that the material from which it is made is

obtainable with a highly finished surface, known as "silver finish " ; that it is consistent and free from flaws and cracks and is easy to work. The body can be made up of sections and bolted together, so that rapid and cheap production is possible, and, provided the material is properly treated and painted, the life of the body is almost indefinite, whilst in the case of damage it can be easily repaired by inserting a new pillar or fitting in an entirely new section. A light rigid body results and a very satisfactorily painted surface is obtainable without a lot of labour.