Patents "Completed.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Sunbeam Valve Gear. An Improved Sparking Plug. Humber Locking Mechanism for Change-speed Gearing. Magneto Armature Construction.

Copies of complete specifications of the patents published an this page can be obtained from the Sales Branch, Patent Office, Holborn, W.C„ at the cost of sixpence for each specification.

THE SUNBEAM MOTOR CR CO., DM. L. COATALEN AND H. C. M. STavuics, No. 10,011, dated fith July, 1915.—The accompanying drawings show a construction of valve-operating gear by which the half-time gearing is eliminated. The tappet is mounted to elide in a hinged guide which permits the tappet to be moved laterally out from the path of the cam. The lifting cam has dormecl on it%a, ftooved cam .comprising two grooves side by side With a cross-over at one point. A slipper lying in these grooves is connected with • the tappet-guide so that as the cam revolves the slipper causes the tappet to be moved. on every alternate revolution oUt of the path of the.cam. Cob:sepiently the valve is operated only on alternate revolutions of the cam.

M. G. W. BURTON, No. 7864, dated 27th May, 1915.—The object of this invention is to provide a ping in which the electrodes are so formed that the spark-gap is kept clean, any carbon or oil deposited on it being automatically removed. The general construction' of the phipand central electrode may be of any desired type, bu4t, the earthed terthinal is foTmed as a Metallic cone having an opening at its apex, which is close to the central electrode.

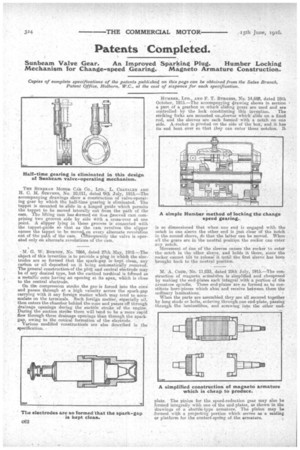

On this compression stroke the gas' is forced into the cone and passes through at a high velocity across the spark-gap carrying with it any foreign matter which may tend to accumulate on the terminals. Such foreign matter, especially oil, then enters the chamber behind the cone and passes off through drainage openings during the sUctien • stroke of the engine. During the stiction stroke there will 'tend to be a more rapid flow through these drainage openings than through the spark gap, owing to the conical formation of the electrode. Various modified constructions are also described in the specification. HUMBER, LTD., AND F. T. BURGESS, No. 14,688, dated 18th October, 1915.—The accompanying drawing shows in section a part of a gearbox m -whch eliding gears are used and are

controlled• by the lock constituting this invention. The striking forks are mounted on„sleeves which slide on a fixed rod, and the sleeves are each foamed with a notch on one side. A-rocker is pivoted on the side of the box, and it has its end bent over so that they can enter these notches. It is so dimensioned that when one end is engaged with the notch in one sleeve the other -end is just clear of the notch in the second sleeve, .s% that the latter can be moved. When all the gears are in the neutral position the rocker can enter any notch. Movement of one of the sleeves causes the rocker to enter the notch in the other sleeve, and holds it there, since the rocker cannot tilt to release it until tho first sleeve has been brought back to the neutral position.

M. A. COD.D, No. 11,033, dated 29th July, 1915.—The construetion of magneto armatures is simplified and cheapened by making the end-plates each integral with a portion of this armature spindle. These end-plates are so formed as to con

• stitute horn-pieces which abut and receive between them the ordinary laminations. When the parts are assembled they are all secured together by long studs or bolts, entering through one end-plate, passing through the laminations, and screwing into the other end plate. The pinion for the speed-reduction gear may also be formed integrally with one of the end-plates, as shown in the drawings of a shuttletyPe armature. The pinion may be formed with a projecting portion which sertes as a seating or platform for the contact-spring of the armature.