THE GARAGE LATHE AND ITS EQUIPMENT.

Page 11

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

How to Secure and Maintain the Efficiency of a Useful Tool which, in a Motor Workshop, is Apt to be Neglected and to Prove Useless when Needed,

THE LATHE in a garage is usually one of the worst equipped parts of the outfit of machinery. It is seldom that a garage proprietor can find enough work to occupy the whole time of a regular turner, so the lathe often becomes " no man's tool!' When any particular machine is used by everyone, it is more difficult to keep it up to concert pitch than when it is continually used by a man skilled in the use of it.

Engineers' turners are seldom skilled in the general run of motor work, and, having no knowledge of other parts of the work of a garage, are not useful men unless sufficient work can be found to keep them occupied entirely on turning jobs. For this reason it is even more important that a garage lathe should be fully equipped at the start, and that every means should be provided whereby the necessary equipment is always at hand when required.

When a small tuiming job has to be done in an ordinary garage there is often more time spent in finding the. necessary tools and appliances than there is in doing the job. This waste of time can be almost entirely avoided if proper means are provided for keeping every article belonging to the lathe in its place, and seeing at a glance if any one tool is missing.

Lathes, as turned out by their makers, have usually only a dark ungetatable cupboard under one of the legs, which is entirely unsuited for storing tools and accessories. We have heard it said that lathe makers cannot use lathes themselves and that they must, apparently, have some other way of producing round articles. One would really think this to be the case when one looks at the very poor accommodation provided for such things as chucks; reamers, drills, etc.

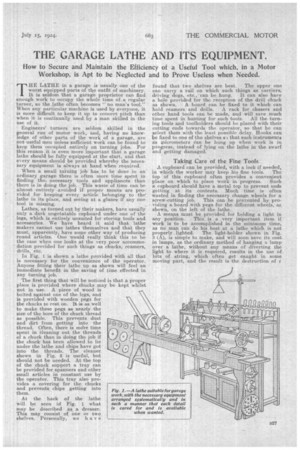

In Fig. 1 is shown a lathe provided with all that is necessary for the convenience of the operator. Anyone fittmg their lathe up as shown will feel an immediate benefit in the saving of time effected in any turning job.

The first thing that will be noticed is that a proper place is provided where chucks may be kept whilst not in use. A piece of wood is bolted against one of the legs, and is provided with wooden pegs for the chucks to rest on. It•is as well to make these pegs as nearly the size of the bore of the chuck thread as possible. This prevents dust and dirt from getting into the thread. Often, there is mere time spent in cleaning out the threads of a chuck than in doing the job if the chuck has been allowed to lie under the lathe and chips have got into the threads. The cleaner shown in Fig. 2 is useful, • but should not be needed. At the top of the chuck support a tray can be provided for spanners and other small articles in constant use by the operator. This tray also provides a covering for the chucks and prevents chips getting into them. .

At the back of the lathe will be seen irf Fig. 1 what may be 'described as a dresser. This may consist of one or two shelves, Personally, we ha v e found that two shelves are best. The upper one can carry a rail on which such things as carriers,

driving dogs, etc., can be hung. It can also have a hole provided for the reception of the drill chuck as shown. A board can be fixed to it which can hold reamers and drills. A rack for chasers and other hand tools can be made, and will save much time spent in hunting for such tools. All the turn-. ing tools and toolholders should be placed with their cutting ends towards the operator, so that he can select them with the least possible' delay. Hooks can be fixed to one of the shelves si that such instruments .

A,nicrometers 6an be hung up when work is in progress, instead of lying on the lathe in the swarf and getting damaged.

Taking Care of the Fine Tools.

A cupboard can be provided, with a lock if needed, in which the worker may keep his fine tools. The top of this cupboard often provides a convenient

place on which to place work in progress. Such a cupboard should have a metal top to prevent suds getting at • its contents. Much time, is often wasted in finding the necessary change wheels for a screw-cutting job. This can be prevented by providing a board with pegs for the different wheels, ac shown, on the left of the lathe.

• A means must be provided for holding a light in any position. This is a very important item if work is to be accomplished in the minimum time, as no man can do his best at a lathe which is not

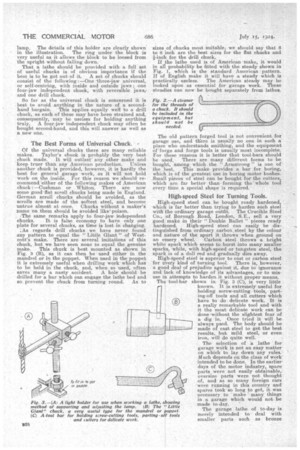

properly _lighted. The light-holder shown in Fig. 3 (A), is simple to make, and will soon save its cost in lamps, as the ordinary method of hanging a lamp over a lathe, without any means of diverting the light to where it is required, results in the use of bits of string, which often get caught in some moving part, and the result is the destruction of r

lamp. The details of this holder are clearly shown in the illustration. The ring under the block is very useful as it allows the block to be loosed from the upright without falling down.

That a lathe should be provided with a full set or useful chucks is of obvious importance if the best is to be got out of it. A set of chucks should consist of the following :—One three-jaw universal, or self-centring, with inside and outside jaws ; one four-jaw independent chuck, with reversible jaws, and one drill chuck.

So far as the universal chuck is concerned it is best to avoid anything in the nature of a secondhand bargain. This applies equally well to a drill chuck, as each of these may have been strained and, consequently, may be useless for holding anything truly. A four-jaw independent chuck may often be bought second-hand, and this will answer as well as a new one.

The Best Forms of Universal Chuck. ,

Of the universal chucks there are many reliable makes. Taylor's chuck is probably the very best chuck made. It will outlast any other make and keep truer than any American production. 'Unless another chuck is provided, however, it is hardly the best for general garage work, as it will not bold work on the inside. For this reason we should recommend 'either of the following makes of American chuck :—Cushmari or Whiton. There are now some goods flat scroll chucks being made in England. German scroll chucks should be avoided, as the scrolls are made of the softest steel, and become untrue almoat at once. Chucks without a maker's Dame on them should be avoided like.poison.

The same remarks apply to four-jaw independent chucks. It is false economy to have only one plate for several chucks, as time is lost in changing.

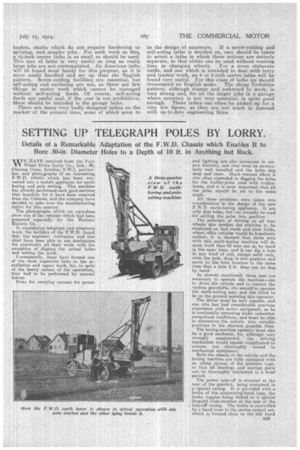

.As regards drill chucks we have never found any pattern to equal the " Little Giant" of Westcott's make. There are several imitations of this chuck, but we have seen none to equal the genuine make. This chuck is best mounted as shown in -Fig. 3 (B), as it can then be used either in the mandrel or in the poppet. When used in the poppet it is extremely useful when drilling work which haa to be held in the chuck, and, when so used, often saves many a nasty accident. A hole should be drilled for a bar which can engage the lathe bed and so prevent the chuck from turning round. As to

sizes of chucks most suitable, we should say that 6 to 8 inch are the best sizes for the flat chucks and 1--inch for the drill chuck. If the lathe used is of American make, it, would in all probability he fitted with the steady shown in Fig. 1, which is the standard American pattern. If of English make it will have a steady which is practically useless. The American steady may be looked upon as essential for garage work. These steadies can now be bought separately from lathes.

The old pattern forged tool is not convenient for garage use, and th'ere is usually no one in such a place who understands smithing, and the equipment of forge and forge tools is usually most incomplete. For these reasons it is better that tool-bars should be used. There are many different forms to be bought, among which the " Armstrong" is one of the best. This make provides a bar for boring, which is of the greatest use in boring motor bushes. Small pieces of steel can be bought for the cutters, which arc far better than forming the whole tool every time a special shape is required.

High-speed Steel for Turning Tools.

High-speed steel can be bought ready hardened, which is far better than trying to harden such steel with the ordinary garage outfit,. The Crucible Steel Co., of Borough Road, London, S.F., sell a very good make in their "Double Bullet" pieces ready

hardened. High-speed steel can easily be distinguished from ordinary carbon, steel by the colour and nature of the spurt it throws when ground on

an emery. wheel. Carbon steel throws a bright white mark which seems to burst into many smaller sparks, while, with high-speed or tungsten steel, the spark is of a dull red and gradually dies away.

High-speed steel is superior to cast or carbon steel for every kind of turning tool. There is, however, a good deal of prejudice against it, due to ignorance and lack of knowledge of its advantages, or to misuse in attempts to harden it without proper means.

The tool-bar shown in Fig. 3 (C), is very little known. It is extremely useful for holding screw-cutting tools,. parting-off tools and all cutters -which have to do delicate work. It is a really remarkable tool and with it the most delibate work can be done 'without the slightest fear of a dig in. Once tried it will be always Ilse& The body should be made of cast steel to get the best results, but mild steel, or even iron, will do quite well.

The selection of a lathe for garage work is not an easy matter on .which to lay down any rules. Much depends on the class of work' intended to be done. In the earlier. days of the motor industry, spare parts were not easily obtainable,. oversize parts were not thought of, and as so many foreign ears were running in this country and' spares took so long to get, it was necessary to make many things in a garage which would not be made to-day.

The garage lathe of to-day is merely intended to deal with smaller parts such as bronze bushes, shafts which do not -require hardening or splining, and simpler jobs. For such work as this, a 6i-inch centre lathe is as small as should be used. This size of lathe is very useful so long as really large jobs are not contemplated. An American lathe will be found most handy for this purpose, as it is more easily handled and set up than the English pattern. Screw-cutting facilities are essential, but self-acting and surfacing are not, as there are few things in motor work which cannot be managed without self-acting feeds. Of course, self-acting feeds are useful and, if the cost is not prohibitive, these should be included in the garage lathe. There are many very badly designed lathes on the market at the present time, some of which seem to

be the design of amateurs. If a screw-cutting and self-acting lathe is decided on, care should be taken to select a lathe in which these actions are entirely separate, so that either can be used without wasting time in changing wheels. For a more elaborate outfit, and one which is intended to deal with lorry and tractorwork, an 8 or 9-inch centre lathe will be found very useful. For this class of lathe we should recommend an English make. The cheap Yorkshire pattern, although clumsy and awkward to work, is very strong and, for all the larger jobs in a garage where accuracy is not very essential, is quite good enough. These lathes can often be picked up for a very low figure, as they are not much in demand with up-to-date engineering firms.