Dual-purpose bulk tankethipper .

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

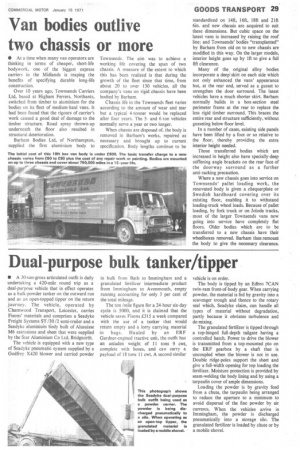

• A 30-ton-gross articulated outfit is daily undertaking a 420-mile round trip as a dual-purpose vehicle that in effect operates as a bulk-powder tanker on the outward run and as an open-topped tipper on the return journey. The vehicle, operated by Charnwood Transport, Leicester, carries Fisons' materials and comprises a Seadyke Freight Systems ST /30/2 semi-trailer and a Seadyke aluminiu'm b'ody built of Alusuisse M6 extrusions and sheet that were supplied by the Star Aluminium Co Ltd, Bridgnorth.

The vehicle is equipped with a new type of Seadyke pneumatic system supplied by a Godfrey X420 blower and carried powder in bulk from Bath to Immingham and a granulated fertilizer intermediate product from Immingham to Avonmouth, empty running accounting for only 3 per cent of the total mileage.

The ton /mile figure for a 24-hour six-day cycle is 5000, and it is claimed that the vehicle saves Eisons £315 a week compared with the use of a tanker that would return empty and a lorry carrying material in bags. Hauled by an ERF Gardner-engined tractive unit, the outfit has an unladen weight of 11 tons 9 cwt, complete with hoses, and can carry a payload of 18 tons 11 cwt. A second similar vehicle is on order.

The body is tipped by an Edbro 7CAN twin-ram front-of-body gear. When carrying powder, the material is fed by gravity into a scavenger trough and thence to the rotary seal which, Seadyke claim, can handle all types of material without degradation, partly because it obviates turbulence and de-mixing.

The granulated fertilizer is tipped through a top-hinged full-depth tailgate having a controlled hatch. Power to drive the blower is transmitted from a top-mounted pto on the ERF gearbox by a shaft that is uncoupled when the blower is not in use. Double ridge-poles support the sheet and give a full-Width opening for top loading the fertilizer. Moisture protection is provided by seam-welding the body lining and by using a tarpaulin cover of ample dimensions.

Loading the powder is by gravity feed from a chute, the tarpaulin being arranged to reduce the aperture to a minimum to avoid dispersal of the fine powder by air currents. When the vehicles arrive in Immingham, the powder is discharged pneumatically into a storage silo. The granulated fertilizer is loaded by chute or by a mobile shovel.