Why Round Pistons?

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

Modern Machining Methods Permit More Convenient Shapes. A Double Advantage Would ,Accrue

By " Azote "

'THE original reason for making "I pistons round in form was that the lathe was the only machine in existence in those early days of the steam engine, and, therefore, accuracy—a relative term—was rendered possible only on parts that could be rnachtned on the lathe, namely, turned.

For a number of years there have been other systems of machining capable of just as great accuracy as that obtained by the circular method— turning or boring. .

As an example of other methods, take the Ford valve guide, which is split, as shown in Fig. 1. The hole is not machined by the circular method; it is broached in halves, along with the face on the centre line, as in Fig. 2. The halves are separately machined and afterwards assembled together, in the valve-guide bore, and the accuracy is quite as high as if' boring and reaming had been the system of production. The broach is.in the form of air endless chain, each link of Which acti di a prc.;gtessiehc. fed cutter., (See Fig. 3.) • Considerati6n Of the conditions of operation Of a piston in its cylinder, cariy, the conviction that the surfaces, machined as they are by turning and boring-, are qtii-te unsuitable ior highs-Peed relative motion.

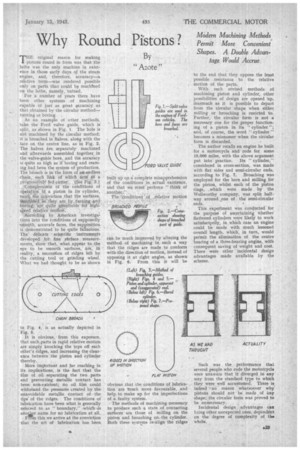

'AcCording to American investiga= tions into the conditions of supposedly sebooth, accurate faces, the supposition is demonstrated to be quite fallacious. The delicate scientific instruments .developed for. fine sttrface measurements, show that, what, appear to the eye to be smooth surfaces, are, in reality, a succesSion of ridges left by the cutting tool or grinding wheel. What we had thought to be as shown

in Fig. 4, is as actually depicted in Fig. 5.

It is obvious, • from this exposure, that such parts in rapid relative motion are simply knocking the tops off each other's ridges, and increasing the clearance between the piston and cylinder thereby.

More important and far reaching in its implications, is the fact that the film of oil separating the two parts and preventing metallic contact has been non-existent; no oil film could withstand the pressures created by the unavoidable metallic contact of the tips' of the ridges. The conditions of lubrication have been what is generally referred to as " boundary," .whieb-.is anogLer name for no lubrication at all.

176m this we arrive at the conviction that the art of lubrication has been built up on 6 complete misapprehension of tbe conditions in actual existence, and that we mint perforce " think of another."

The -conditions of relative motion can be much improved by altering the method of machining in such a way that the ridges are made to conform

with direction of motion, instead of opposing it at right angles, as shown in Fig. 6. From this it will be

obvious that the conditions of lubrication are Much more favourable, and• help to make up for the imperfections of a faulty system.

The methods of machining necessary to produce such a state of contacting sat-faces • are those of milling on the piston and broaching on,-the cylinder. Both these systems re-align the ridges

to the end that they oppose the least possible resistance to the relative motion of the parts.

With such revised methods of machining piston and cylinder, other possibilities of design are opened 'up, inasmuch as it is possible to depart from the circular shape when either milling or broaching is resdrted to. Further, the circular form is not a necessary one for the proper functioning of a piston in its "cylinder "; and, of course, the word " cylinder " becomes a misnomer when the circular form is discarded.

The author recalls an engine be built for a motorcycle and rode for some 10,000 miles, with the above argument put into practice. Its "cylinder," considered in cross-section, was made with flat sides and semi-circular ends, according to Fig. 7. Broaching was employed for the bore and milling for the piston, whilst each of the piston rings„ which were made by the Weliworthy company, was split halfway around one of the semi-circular ends. • This experiment was conducted for the purpose of ascertaining whether flattened cylinders were likely to work satisfactprily, in which case an engine could be made with much lessened overall length, which, in turn, would permit the elimination of the centre bearing of a three-bearing engine, with consequent saving of weight and cost. There were other incidental design advantages made available by the scheme.

Such was the performance that several people who rode the motorcycle were unaware that it diverged in any way from the standard type to which they were well accustomed. There is indeed -no reason whatsoever why pistons should not be made of any shape; the circular form was proved to be unnecessary.

Incidental design • advantages Can bring other unexpected ones, dependent on the degree of complexity of the whole.