HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

471.—An Improved Stop for the Vulcan Steering.

In Hint on Maintenance No. 437 we gave details of a special stop by which the movement of the drop arm of the Vulcan lorry can be restricted, thus preventing the tyres from fouling the steering rod and causing wear on both.

One of our readers has adopted the idea on several lorries of which he is in charge, but he found that the ordinary stud soon broke off. He, therefore, made use of another type of stop which was not only much stronger, but also permitted adjustment, as it included an eccentric roller which could be turned and locked at the desired position.

The slot carrying the roller was turned from 1-in. diameter mild steel, screwed both ends On. Whitworth and with a collar left between the threads. The eccentric roller was cut from a piece of mild steel 11 in. diameter. It has a thickness of in. and the eccentric hole drilled in it is fin. clearance, so that it can pass over the thread and on to the plain part of the stud. The short end of the stud should be of such length that it can be passed through a hole drilled in the frame side member and there locked by two nuts.

472.—How to Prevent Oil Leakage Along they Magneto Drive of the Dennis.

Oil leaks sometimes occur along the magneto drive shaft of the Dennis power unit, and unless the correct prodedure is adopted to stop these leaks the trouble may develop still farther.

The usual means employed is to fit a felt washer in the annular oil return groove of the case, but this is quite a, mistake and the following procedure is considered to be very much better.

If being done for the first time on any particular engine, it is better to take the magneto cross-shaft right out ; it will then be found that the bearing at the magneto end is of the split type and that slight play has developed in it. This play is the cause of the trouble, and it may be taken up by -closing the halves of the bearing on to B44

the shaft in a similar manner to that employed for an .ordinary big-end. The brasses should also be lightly coated with solder, so that the cross-shaft cover can grip the bearing firmly. If a felt washer has been fitted previously this should be removed and care taken that the oil-return hole in the engine case is quite clear.

After dealing with the first engine it will be found unnecessary in subsequent tasks of the same description to remove the cross-shaft, and this saves much time as it avoids interference with the magneto and water pump.

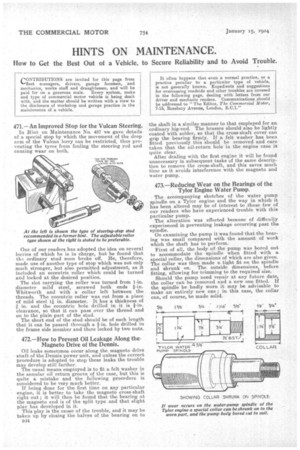

473.—Reducing Wear on the Bearings of the Tylor Engine Water Pump.

The accompanying sketches of the water pump spindle on a Tyler engine and the way in which it has been altered may be of interest to _those few of our readers who have experienced trouble with this particular pump.

The alteration was effected because of difficulty experienced in preventing leakage occurring past the spindle.

On examining the pump it was found that the bearing was small compared with the amount of work which the shaft has to perform.

First of all, the body of the pump was bored out to accommodate the spindle when fitted with a special collar, the dimensions of which are also given. The collar was then made a tight fit on the spindle and shrunk on. The outside dimensions, before fitting, allowing for trimming to the required size. Should the pump need repair at any future date, the collar can be removed and a new one fitted. If the spindle be badly worn it may be advisable to make an entirely new one ; in this ease, the collar can, of course, be made solid.