KEY TO SUCCESS

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Curtain-sided trailers have grown in popularity with potential distribution customers, yet Robsons' fleet consisted mainly of platforms. What could it do to transform its fleet at a minimal cost? Key Leasing had the answer.

• Robsons is probably one of the bestknown names in the haulage world. Few regular motorway drivers can have failed to see the company's familiar maroon and cream lorries.

Under the surface, however, much has changed in this long-established company. Since the start of the year it has been part of the Bunzl Transportation group, a rapidly expanding organisation that now includes United Carriers and Thompson Jewitt, the freight forwarder.

Development has meant a rethink of the company's strategy, and a change in its marketing emphasis. For some years Robsons was a subsidiary of its major customer, United Glass, and its energies were focussed primarily on serving the needs of its parent. Under its new managing director, former Pickfords man Simon Bellinger, Robsons is looking for markets outside its traditional area — especially in distribution.

The change in direction has involved two important developments in the company's vehicles. One is the introduction of a new black and white livery, which is being applied steadily across the fleet.

More far-reaching in many ways has been a change in the type of equipment offered to customers. Until recently platform trailers predominated in the fleet but, in the words of John Walter, the operations director: "These days curtainsiders are far more acceptable to many customers. They are more hygienic, less damage-prone and they allow more sensitive product handling."

The company already has in hand an extensive fleet replacement programme, but it wanted to achieve results more quickly than this would allow. It also wanted a cost-effective solution that made the best possible use of its existing platform trailers.

The answer to this puzzle has been provided by Key Leasing, of Cheadle, Cheshire. This company has agreed to buy a batch of platform trailers from Robsons, rebody them as curtain-siders and then lease them back to the company in their new form.

It is a major project involving 41 trailers, and they are being drawn from the company's five major and three smaller depots around the country. There is a remarkable degree of consistency about the trailers themselves; they were all built by Crane Fruehauf, and all are tandem-axle models with conventional mechanical suspension.

"We decided we didn't want to alter the suspension or uprate the capacity," says fleet engineer Peter Walmsley. "So that meant we didn't have to do any major rebuilding. All that was necessary was to overhaul the existing chassis equipment to bring it up to scratch."

Robsons itself is doing this work at its big depot at Carlisle. "Basically we're shot-blasting the chassis, replacing any worn-out parts, and then putting the trailers through their annual test if they need it. Then we're sending them to the bodybuilders for conversion."

Two bodybuilders are doing the work — Southfields Coachworks and York. The curtain-sided bodies are distinctive in having a side-aperture height of 2.3m which was required by one of Robsons' main customers. They feature sliding side posts to allow variable side access, and have container doors at the rear.

OWN SPECIFICATION

Technically Key Leasing is the customer for this work although, as Peter Walrnsley explains: "The bodybuilders are doing the job exactly to our specification, just as if the trailers were still our own."

Most of the trailer chassis are between eight and 10 years old. Key Leasing is hiring them back on an initial seven-year term, after which, if their condition warrants it, the deal will be extended for a further two years. "The point about trailers," says John Walter, "is that by the time they're as old as these, a lot of the main components have already been refurbished or renewed. So we're hoping there won't be much to go wrong." The arrangement with Key Leasing is an operating lease — that is, one where the operator has use of the equipment, but it remains the property of the finance company. These deals have become increasingly common recently because of the tax implications; the equipment does not appear on the user's balance sheet, and the costs can be claimed against tax as an allowable expense. In a straight finance lease, the equipment does appear on the balance sheet.

In the past, operating leases have tended to be offered on new or relatively recent equipment, since it is fundamental to the concept that the equipment should retain a realisable value at the end of the term of the contract.

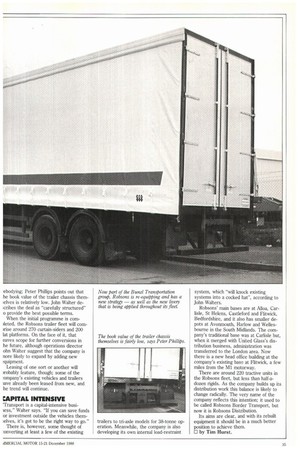

So the Robsons deal, covering wellused trailers, is rather unusual. Key Leasing's finance manager Peter Phillips emphasises, however, that it "is a fullyfledged operating lease, with proper residuals built in".

The total value of the Robsons deal is thought to be in the region of 2300,000. Most of the cost is taken up with the ebodying; Peter Phillips points out that he book value of the trailer chassis them;elves is relatively low. John Walter de;cribes the deal as "carefully structured" o provide the best possible terms.

When the initial programme is corn)leted, the Robsons trailer fleet will cornwise around 270 curtain-siders and 200 lat platforms. On the face of it, that eaves scope for further conversions in he future, although operations director ohn Walter suggest that the company is nore likely to expand by adding new !quipment.

Leasing of one sort or another will wobably feature, though; some of the ;ompany's existing vehicles and trailers iave already been leased from new, and he trend will continue.

CAPITAL INTENSIVE

Transport is a capital-intensive busiless," Walter says. "If you can save funds or investment outside the vehicles them;elves, it's got to be the right way to go."

There is, however, some thought of :onverting at least a few of the existing system, which "will knock existing systems into a cocked hat", according to John Walters.

Robsons' main bases are at Alloa, Carlisle, St Helens, Castleford and Flitwick, Bedfordshire, and it also has smaller depots at Avonmouth, Harlow and Wellesbourne in the South Midlands. The company's traditional base was at Carlisle but, when it merged with United Glass's distribution business, administration was transferred to the London area. Now there is a new head office building at the company's existing base at Flitwick, a few miles from the M1 motorway.

There are around 220 tractive units in the Robsons fleet, but less than half-adozen rigids. As the company builds up its distribution work this balance is likely to change radically. The very name of the company reflects this intention; it used to be called Robsons Border Transport, but now it is Robsons Distribution.

Its aims are clear, and with its rebuilt equipment it should be in a much better position to achieve them.

0 by Tim Hurst.