QUALITY ON THE RACK

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

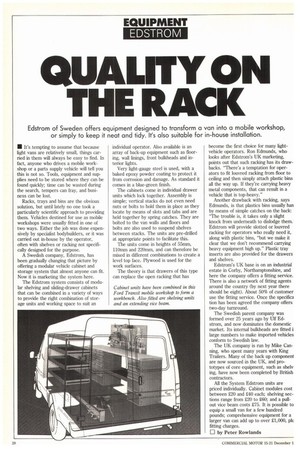

Edstrom of Sweden offers equipment designed to transform a van into a mobile workshop, or simply to keep it neat and tidy. It's also suitable for in-house installation.

• It's.tempting to assume that because light vans are relatively small, things carried in them will always be easy to find. In fact, anyone who drives a mobile workshop or a parts supply vehicle will tell you this is not so, Tools, equipment and supplies need to be stored where they can be found quickly; time can be wasted during the search, tempers can fray, and business can be lost.

Racks, trays and bins are the obvious solution, but until lately no one took a particularly scientific approach to providing them. Vehicles destined for use as mobile workshops were usually fitted in one of two ways. Either the job was done expensively by specialist bodybuilders, or it was carried out in-house by the operator, often with shelves or racking not specifically designed for the purpose.

A Swedish company, Edstrom, has been gradually changing that picture by offering a modular vehicle cabinet and storage system that almost anyone can fit. Now it is marketing the system here.

The Edstrom system consists of modular shelving and sliding-drawer cabinets that can be combined in a variety of ways to provide the right combination of storage units and working space to suit an individual operator. Also available is an array of back-up equipment such as flooring, wall linings, front bulkheads and interior lights.

Very light-gauge steel is used, with a baked epoxy powder coating to protect it from corrosion and damage. As standard it comes in a blue-green finish.

The cabinets come in individual drawer units which lock together. Assembly is simple; vertical stacks do not even need nuts or bolts to hold them in place as they locate by means of slots and tabs and are held together by spring catches. They are bolted to the van walls and floors and bolts are also used to suspend shelves between stacks. The units are pre-drilled at appropriate points to facilitate this.

The units come in heights of 55mm, 110rnm and 220rnm, and can therefore be mixed in different combinations to create a level top face. Plywood is used for the work surfaces.

The theory is that drawers of this type can replace the open racking that has become the first choice for many fightvehicle operators. Ron Edmunds, who looks after Edstrorn's UK marketing, points out that such racking has its drawbacks. "There'a a temptation for operators to fit louvred racking from floor to ceiling and then simply attach plastic bins all the way up. If they're carrying heavy metal components, that can result in a vehicle that is top-heavy."

Another drawback with racking, says Edmunds, is that plastics bins usually han by means of simple catches on the back: "The trouble is, it takes only a slight knock from underneath to dislodge them. Edstrom will provide slotted or louvred racking for operators who really need it, along with plastic bins, "but we make it clear that we don't recommend carrying heavy equipment high up." Plastic tray inserts are also provided for the drawers and shelves.

Edstrom's UK base is on an industrial estate in Corby, Northamptonshire, and here the company offers a fitting service. There is also a network of fitting agents around the country (by next year there should be eight). About 50% of customer use the fitting service. Once the specifica tion has been agreed the company offers two-day tuniround.

The Swedish parent company was formed over 25 years ago by Ulf Edstrom, and now dominates the domestic market. Its internal bulkheads are fitted large numbers to make imported vehicles conform to Swedish law.

The UK company is run by Mike Canning, who spent many years with King Trailers. Many of the back up component are now sourced in the UK, and prototypes of core equipment, such as shelv ing, have now been completed by British contractors.

All the System Edstrom units are priced individually. Cabinet modules cost between £20 and 240 each; shelving sections range from £20 to £60; and a pullout vice beam costs .275. It is possible to equip a small van for a few hundred pounds; comprehensive equipment for a larger van can add up to over £1,000, ph fitting charges.

by Peter Rowlands