Three go for new generation option

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

THREE major chassis manufacturers — Daf, Foden and Ivaco — have taken up an option on 250 pre-production new generation Eaton twin countershaft splitter transmissions.

The 12-speed gearbox has a conventional four-position single H pattern gate with three splitter gears operated by a simple switch mechanism in each position.

The twin-splitter gearbox is the first of several new Eaton transmissions that will become available over the next few years, aimed specifically at reducing driver effort and minimising whole life cost.

Each splitter gear can be preselected and operated by the throttle; only four stick and clutch movements are needed over the 12-ratio range.

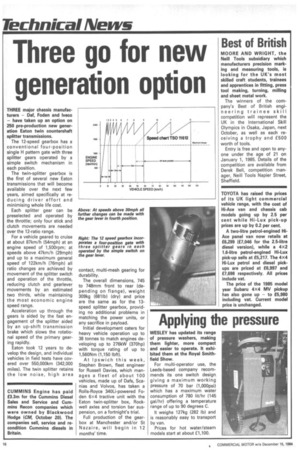

For a vehicle geared to cruise at about 87km/h (54mph) at an engine speed of 1,500rpm; at speeds above 47km/h (29mph) and up to a maximum general speed of 122km/h (76mph) all ratio changes are achieved by movement of the splitter switch and operation of the throttle, reducing clutch and gearlever movements by an estimated two thirds, while maintaining the most economic engine speed range.

Acceleration up through the gears is aided by the fast engagement of the splitter aided by an up-shift transmission brake which slows the rotational speed of the primary gearing rapidly.

Eaton took 12 years to develop the design, and individual vehicles in field tests have covered over 550,000km (342,000 miles). The twin splitter retains the low noise, high area contact, multi-mesh gearing for durability.

The overall dimensions, 745 to 748mm front to rear (depending on flange), weight 309kg (681Ib) (dry) and price are the same as for the 13speed splitter gearbox, providing no additional problems in matching the power units, or any sacrifice in payload.

Initial development caters for heavy vehicle operation up to 38 tonnes to match engines developing up to 276kW (370hp) with torque rating of up to 1,560Nm (1,150 Ibft).

At Ipswich this week, Stephen Brown, fleet engineer for Russell Davies, which manages a fleet of about 100 vehicles, made up of Dafs, Scanias and Volvos, has taken a Rolls-Royce 340Li-powered Foden 6x4 tractive unit with the Eaton twin-splitter box, Rockwell axles and torsion bar suspension, on a fortnight's trial.

Full production of the gearbox at Manchester and/or St Nazaire, will begin in 12 months' time.