Target 1975 for Europe's four-firm truck project

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

by Gibb Grace, who takes a closer look at one of the partners' products

• The first results, in terms of hardware, of the co-operative design and production of a range of medium /lightweight trucks and vans by DAF, Saviem, Volvo and Klo cknerHumboldt-Deutz (M agiru sDeutz) are likely to be seen in 1975. Without attracting much attention in Britain, the four partners have been making considerable design progress following their initial announcement a year ago.

It is already settled that all the models involved will have a common cab, and that this will almost certainly be constructed by Saviem. Engines will vary with the individual manufacturer and the chassis will probably be of welded construction.

It is not intended that identical vehicles should be produced for each company, and there will certainly not be a common make name: each partner will sell distinctive versions under its own name, I was assured recently during a Continental visit. But the whole project — aimed at countering British strength in this sector of the truck market, from 6 to 12 tons — is based on the common use of major components. Some of these may be new, but engines will be based on existing designs.

A company controlling the project, in which all four have equal financial stakes, has been set up at Eindhoven under the director-generalship of M. Van der Leggte. The company is European Truck Design BV; a sister organization has been established in Paris to supervise the development of common components and to undertake testing. The starting capital is £170,000, but a great deal of the contribution will be in the form of staff and know-how. Already each company has seconded engineers and draughtsmen to the central design office.

The co-operative venture is typical of the way commercial vehicle manufacture is moving in Europe; as the cost of tooling and development increases, more and more use is being made of shared components, and the French partner in the four-firm deal, Saviem, already has extensive experience of a very fruitful agreement with MAN.

Saviem (Societe Anonyme des Vehicules Industriels et d'Equipements Mecaniques) is the subsidiary of the Renault group producing commercial vehicles and buses and as such is France's second largest producer. (In 1955 the commercial vehicle department of Regie Renault absorbed two other French truck manufacturers, Somua and Latil, to form Saviem.) Since 1955 Saviem has gradually increased its share of the French market from 15 to 23 per cent with an up-to-date range of vehicles of between 3.5 and 38 tonnes gvw output is about 31,000 units.

The main vehicle assembly plant is at Blainville, near Caen in Normandy, while engines, automatic transmissions and other parts are made at Limoges.

Saviem, aware of its relatively small size and the need to maintain a high standard of product, has for some time had trading agreements with other European manufacturers. As early as 1962 Saviem was using MAN engines and in 1968 the two firms joined forces in the design of a common range of "European" trucks and tractive units from 15 to 38 tonnes gvw. Both Saviem and MAN produce components for the trucks and these are interchanged between them to achieve a financial balance.

In these larger vehicles MAN makes the engines and axles, and Saviem makes the cab, for example. In the case of the largest engine used, a 300 bhp V8, the European co-operation goes even further. This engine is one of the range produced from blocks cast by Daimler-Benz in Germany under a mutual benefit plan. The MAN and • Daimler-Benz engines, though basically of the same design, use separate heads and fuel injection systems. The large engine used in heavy Saviem trucks is built in Munich by MAN from blocks cast in Germany by Daimler-Benz. Under a separate agreement, Saviem. supplies MAN with components such as engines, cabs and gearboxes for middle-range trucks (7.5 to 12 tonnes gvw) built by MAN for the German market.

The heavy "European" vehicles are sold under the Saviem and MAN names in France and Germany respectively, with sales to other countries subject to agreed trading arrangements. In addition, in its own market each company sells certair types of vehicle produced by the other. Foi example, Saviem markets the off-roac MAN trucks in France while lightweighSaviem vehicles are sold in Germany 1:1. MAN. The dealer networks of Savien and MAN service vehicles of bot1 makes.

Saviem have forged similar links with the Italian Alfa Romeo company, Alfa Romeo, or example, manufacture for Saviem a 3.enault-Saviem diesel of 76 /92 bhp which, ncidentally, uses a MAN combustion )rocess. Alfa Romeo and Saviem also :o-operate in the production of a ront-wheel-drive low-loading delivery van, .gain sold and serviced by dealers of both irms. Also Saviem vehicles under 6 tons vw are sold by Alfa Romeo dealers in tal y.

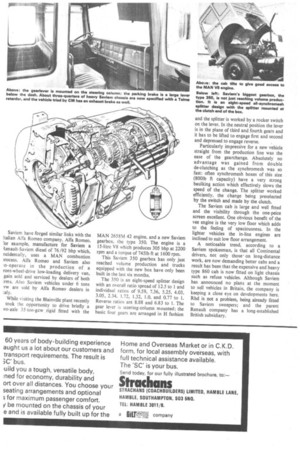

While visiting the Blainville plant recently took the opportunity to drive briefly a 'o-axle 35-ton-gcw rigid fitted with the MAN 2658M 42 engine, and a new Saviem gearbox, the type 350. The engine is a 15-litre V8 which produces 305 bhp at 2200 rpm and a torque of 7451b ft at 1600 rpm.

This Saviem 350 gearbox has only just reached volume production and trucks equipped with the new box have only been built in the last six months.

The 350 is an eight-speed splitter design with an overall ratio spread of 12.5 to 1 and individual ratios of 9.59, 7.36, 5.25, 4.03, 3.05, 2.34, 1.72. 1.32, 1.0, and 0.77 to 1. Reverse ratios are 8.88 and 6.83 to I. The gear lever is steering-column mounted; the basic four gears are arranged in H fashion and the splitter is worked by a rocker switch on the lever. In the neutral position the lever is in the plane of third and fourth gears and it has to be lifted to engage first and second and depressed to engage reverse.

Particularly impressive for a new vehicle straight from the production line was the ease of the gearchange. Absolutely no advantage was gained from double de-clutching as the synchromesh was so fast: often synchromesh boxes of this size (8001b ft capacity) have a very strong baulking action which effectively slows the speed of the change. The splitter worked efficiently, the change being preselected by the switch and made by the clutch.

The Saviem cab is large and well fitted and the visibility through the one-peice screen excellent. One obvious benefit of the vee engine is the very low floor which adds to the feeling of spaciousness. In the lighter vehicles the in-line engines are inclined to suit low floor arrangement.

A noticeable trend, according to a Saviem spokesman, is that all Continental drivers, not only those on long-distance work, are now demanding better cabs and a result has been that the expensive and heavy type 860 cab is now fitted on light chassis such as refuse vehicles. Although Saviem has announced no plans at the moment to sell vehicles in Britain, the company is keeping a close eye on developments here. Rhd is not a problem, being already fitted to Saviem sweepers; and the parent Renault company has a long-established British subsidiary.