ADVAI\ DESIGN IN NEW GUYS

Page 54

Page 55

Page 56

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

ELEyE.N forward-control and three normal-control chassis comprise the new Guy Invincible range of heavy-duty goods vehicles announced today. To meet a wide variety of operating conditions in both home

and export markets a comprehensive choice of power units, wheelbases and axle configurations is offered. Emphasis has been placed upon obtaining maximum reliability from the chassis components, and a high standard of driving comfort is given by the new Guy-built cab.

All the new vehicles abound with interesting features, including 12-in.-deep chassis frames; 4-in.-wide springs; eight-wheel brakes optional on the eight-wheelers and dual-circuit air brakes standard on all models; paper-element air cleaners; the option of a new design of overhead-worm-drive axle, the gearing of which may be replaced by a double-reduction assembly; the option of a limited-slip third differential on double-drive bogies; and an air servo for the hand brake.

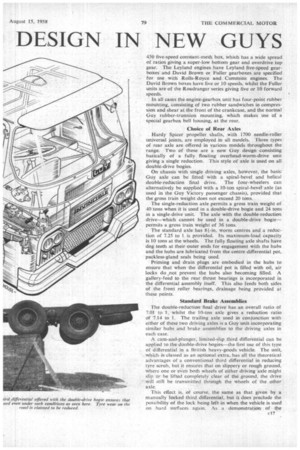

Outstanding in appearance and appointment, the new Guy cab is one of the most advanced designs made by a vehicle manufacturer anywhere in Europe. Its distinctive appearance is given by the deep two-piece, wrap-round windscreen, the original radiator grille, paired headlights and a modern bumper design. The cab is 7 ft. 6 in. wide for maximum comfort, and detail fittings include a cigarette lighter, door-operated interior lights and even a socket for an electric shaver.

There are four four-wheelers, two twin-steer six-wheelers, three ordinafy six-wheelers and two eight-wheelers, all with forward control, whilst the bonneted range is based on the fourand six-wheeled chassis. The four-wheeiers.are offered with wheelbases of 8 ft. 9 in., 11 ft.. 6 in., 15 ft. 6 in. and 17 ft. 9 in., the longest being suitable for a 24-ft. 6-in. body. The twin-steer six-wheelers have 17-ft. 9-in. and 20-ft. wheelbases, whilst the rear-bogie six-wheelers are available with 11-ft., 13-ft. 9-in. and 17-ft. 9-in. wheelbases. The wheelbases of the two eight-wheelers are 13 ft. 9 in. and 17 ft.9 in.

Five makes of oil engine are offered throughout the new range. There is a Choice of two Gardner units, the 112-b.h.p. 6LW and the new 6LX 150-b.h.p. engine, full details of which were announced on July 25, Leyland 0.600 and 0.680 125-b.h.p. and 1,50-b.h.p. units arc offered (-16 and Rolls-Royce C6 engines of up to 210 b.h.p. can also. be fitted, with the further options of British-built Cummins HU, HF and NH units with power outputs of up to 210 b.h.p., and Meadows 6DC 500 or 6DC 630 engines.

Whichever power unit is fitted, certain ancillary details apply, such as the provision of a transverse exhaust system carried ahead of the front wheels and the use of a Purolator Micronie paper-element air cleaner with a cold-air intake. Hydraulic actuation is employed for the throttle,

A Morris block-type radiator, pressurized to 4 p.s.i.. is employed with any of the power units. This radiator has been specially developed for the new range and its squat outline permits the use of a deep windscreen. Provision is made for mounting an oil cooler across the front of 016-block and the fan is closely cowled fortnaximurn efficiency. The radiator is rubber-mounted on two horizontal bolts to allow for easy removal.

Each of the Meadows engines is available with a Meadows 350 five-speed constant-mesh of synchromesh gearbox, whilst the two Gardner engines have the Meadow,;

450 five-speed constant-mesh box, which has a wide spread of ratios giving a super-low bottom gear and overdrive top gear. The Leyland engines have Leyland five-speed gearboxes. and David Brown or Fuller gearboxes are specified for. rise with _Rolls-Royce and. Cummins engines. The David Brown boxes have five or 10 speeds, whilst the Fuller units are of the Roadrariger series giving five or 10 forward speeds.

. In all cases the engine-gearbox unit has four-point rubber mou'nting, consisting of two rubber sandwiches in compression and shear at the front of the crankcase, and the normal Guy rubber-trunnion mounting, which makes use of a special gearbox bell housing, at the rear.

Choice of Rear Axles Hardy Spicer propeller shafts, with 1700 needle-roller universal joints, are employed in all models. Three types of rear axle are offered in various models throughout the range. Two of these are a new Guy design consisting basically of a fully. floating overhead-worm-drive unit giving a single reduction. This style of axle is used on all double-drive bogies.

On chassis with single driving axles, however, the basic Guy axle can be fitted with a spiral-bevel and helical double-reduction final drive. The four-wheelers can alternatively be supplied with a 10-ton spiral-bevel axle (as used in the Guy Victory passenger chassis), provided that the gross train weight does not exceed 20 tons, The single-reduction axle permits a gross train weight of 40 tons when it is used in a double-drive bogie and 24 tons in a single-drive unit. The axle with the double-reduction drive—which cannot be used in a double-drive bogie— permits a gross train weight of 36 tc■ns.

The standard axle has worm centres and a reduc tion of 7.25 to 1 is provided. Its maximum-load capacity is 10 tons at the wheels. The fully floating axle shafts have dog teeth at their outer ends for engagement with the hubs and the hubs are lubricated from the centre differential pat, packless-gland seals being used.

Priming and drain plugs are embodied in the hubs to ensure that when the differential pot is filled with oil, air locks do not prevent the hubs also becoming filled. A gallery-feed to the rear 'thrust bearings is incorporated in the differential assembly itself. This also feeds both sides of the front roller bearings, drainage being provided at these points.

Standard Brake Assemblies The double-reduction final drive has an overall ratio of 7.01 to 1, whilst the 10-ton axle gives a reduction ratio Of 7.14 to 1. The trailing axle used in conjunction with either of these two driving axles is a Guy unit incorporating similar hubs and brake assemblies to the driving axles in each case.

A cam-and-plunger. limited-slip third differential can be applied to the double-drive bogies—the first use of this type of differential in a British heavy-goods vehicle. The unit, which is classed as an optional extra, has all the theoretical advantages of a conventional third differential in reducing tyre scrub, but it ensures that on slippery or rough ground, where one or evenboth wheels of either driving axle might slip or he lifted completely .clear of the. ground, the drive Will -still be transmitted through the wheels of the other axle.

This effect is. of course, the same as that given by a manually locked third differential, but it does preclude the possibility of the lock being left -in when the vehicle is used on hard surfaces again. As a demonstration.. of • the

effectiveness of this differential, one of the prototype Invincible eight-wheelers was backed on to a ramp, so that the wheels of the fourth axle were completely clear of the ground, and the chassis was then driven forward again, a feat which would be impossible with a conventional third differential. It is claimed that the extra cost of the limited-slip differential should be recovered within six months in terms of increased tyre life.

A Kirkstall front axle is employed in all Invincible models, this being similar in general design to the axle fitted to the Victory chassis. Taper-roller bearings are employed for the king-pins. • Conventional semi-elliptic leaf springs 4 in. wide form the front and rear suspension on all models. Single-rate springs are fitted at the rear and those chassis with bogies have a balance beam, the articulation of which allows a difference in height of 12 in. at the hubs on one side. It is expected, however, that a fully articulated suspension for rear bogies will be developed later.

Constant Bogie Centres

The rear springs are 48-1 in. long and their geometry is such that there is little change in the distance between axles, whether laden or unladen. This is important in helping to reduce the slight steering effect which can be caused at rear bogies when cornering, particularly with high loads. The bogie bracket forms an oil reservoir with a wick for the fulcrum pin.

Four-wheelers and twin-steer six-wheelers have 60-in.-long progressive rear springs, which are used in conjunction with helper springs, whilst the front springs on all models are triple-rate progressive units 50 in. long.

Girling wedge-operated two-leading-shoe .brakes are used throughout the range, the rear brakes having the two-leadingshoe .effect in both forward and reverse• directions. All the brakes are 151 in, in diameter, the facing widths being 5 in. at the front and 7 in. at the rear. The shoes carry 1-in.-thick moulded facings.

Eight-Wheel brakes, now offered on the eight-wheelers, make for safe retardation and good anti-fade properties, and on all models the brakes are actuated by Bendix Westinghouse diaphragm-type air chambers. Dual-circuit systems are applied throughout the range.

In the case of the eight-wheelers, the brakes on the first and third axles have a separate circuit from those on the second and fourth axles. On rear-bogie six-wheelers the first and second axles have one circuit and the third axle a separate one. In the case of the twin-steer models, the first axle has its own circuit and the second and third a separate one. Twin air reservoirs are fitted and the brakes are actuated through a frame-mounted dual E valve, the linkage being from a conventional brake pedal.

Power for the brakes is provided by a 10-cu.-ft. air-cooled compressor driven from the gearbox layshaft in the case of Gardner-engined chassis, and by a 500 Tu-Flow water-cooled compressor when a Meadows engine is fitted.

Air-assisted Hand Brake

An entirely new form of hand brake has been developed for the Invincible range. Briefly, it consists of a straight rack with fine and coarse teeth actuated by a long cranked lever, the handle of which lies on the cab floor and is pulled upwards. An important innovation is that an air-pressure servo is coupled to the hand-brake rack to give single-pull operation.

If there is no air pressure the brake functions as a multi-pull unit. Initial movement of the lever acts on the coarse teeth and takes up the primary play, whilst the second pull works through the fine teeth and gives full application against the drums. The brake permits controlled release to simplify starting on hills.

Manes cam-and-double-roller steering has been installed in all models, and is platform mounted, so that the steering box lies outside the drop arm, the column being free-standing. This layout ensures that the steering wheel, which decides the position of the driving seat, is well to the side of the cab, whilst at the same time the drop arm lies close to the chassis frame. Hence the drag link also is close to the frame and, as this position imposes less restriction on the steering lock, all the models have excellent turning circles.

The steering has a ratio of 28.5 to 1 and a 20-in.-diameter (7:18

white-rimmed wheel is fitted. Adamant hydraulic servo equipment is offered as an optional extra and is of the type in which the operating valves are integral with the steering box. The actuating:-ram piston rod acts directly on du: drop arm on those chassis with single front axles, and on the centre relay arm on twin-front-axlecl chassis.

Frames of all the four-wheelers, except the tipper model and the six-wheeled tractor, are fabricated from A-in.-thick steel pressings, whilst the four-wheeled tipper and the sixand eight-wheelers. have A-in.-thick frames. In all cases the side members are 12 in. deep, with 3-in, flanges, the depth being constant between the centre line of the front axle to a point beyond the rear axle. The upper flanges are ramped down by 74 in. at the front to lower the steering position.

Fitted bolts are used throughout the assembly of the frame and, except on the 17-ft. 9-in.-wheelbase four-wheeler, there are no flitch plates. Because wide-base wheel rims are standard throughout the new range it has been necessary to crank the frame side members slightly inwards, adjacent to the rear

wheels, as otherwise the springs would have to had been underslung and the frame height would have been increased. The rear frame height of all laden chassis on 10.00-20-in. tyres is 3 ft. 1 in.

Michelin X tyres are standard on all the new models and Sankey heavy-duty B/7 wheels are employed when 10.00-20-in. X tyres are fitted; Dunlop B 6.5 wheels are used with 9.00-20-in. tyres. The 10.00-20-in. tyres are standard all round on all four-wheelers and on the normal-control six-wheelers, whilst 9.00-20-in, equipment is fitted to the six-wheeled tractors and the eight-wheelers.

The six-wheeled trucks and tippers have 10.00-20-in, front tyres and 9.00-20-in, rear tyres. Alternative tyres of up to 11.00-22 in. can be supplied on any chassis. Tractors have no spare wheels. On tippers the wheel is located at the right-hand side, and on all other models it is winch-mounted at the rear of the frame.

A choice of 40-gal. or 60-gal. fuel tanks is available, but on tractors 50-gal. tanks are standard. The tanks are carried on the left of the frame; and on the right there is a crate housing Four 6v. batteries with a capacity of 108 amp.-hr. The batteries ire protected by a removable plastics cover.

An instrument panel mounted, on the steering column is tupplied with each chassis. The nacelle is semi-circular and aas a cowl along its forward edge to prevent the panel lights 7eftecting in the windscreen. The instruments include an :lectrically operated speedometer, ammeter and fuel, tempera

mre, oil and air-pressure gauges. There is an air-pressure ;auge for each circuit.

There are six warning lights, one for each air circuit and one 7.ach for oil pressure., water temperature, dynamo charging and or the flashing direction indicators. These warning lights are al a new type which glow all the time when the master switch s on, but grow brighter should a fault occur. This avoids the Joubt which frequently arises with the kind of warning light :hat goes out to indicate a failure, when an absence of light -night be caused by a faulty bulb.

Electric Shaver Offered Panel lighting.is "controlled by a rheostatic switch and other ittings include inspection-lamp sockets (a lamp is provided in be tool kit). cigarette lighter, hearer, ind socket for• use with a Remington Super -6(1 De luxe -24v./240v. electric thayer, which is offered as an optional .,:xtra. An Ekco radio is also offered, his being mounted above the wind;erect).

The cab assembly is in two sections :onsisting of an all-steel base and an ill-plastics superstructure. The base as a pressed-angle sub-frame which :arries four Metacone rubber mountrigs and it protrudes beyond the upper >ection all round to minimize the risk )f damage to the plastics panels. The lase sub-assembly consists of the subframe, floors, wings, front panel and he plastics three-niece engine cowl. sound and heat insulation is provided )y 1-in.-thick plastics foam around the nsicle of the engine cowl and under the floors.

A flat datum line for the base assembly makes it easy for werseas coachbuilders to construct cabs on the standard base ind simplifies the design of the upper section, which is conlected to the base by six bolts with rubber strip forming.

seal. The cab top is easily removed, particularly as the dectrical cables which feed the wipers, and radio when fitted, are combined into a socket and plug which can quickly be disconnected. The large two-piece windscreen has a total area of 2,600 sq. in. Other glazing includes wind-downdoor windows, fully hinged door ventilator lights, (leen rear quartet lights and a centre :fight, all totalling 1,500 sq. in. For use in hot climates, an extetnal double skin is Offered to

provide additional ventilation. A large. external full-width• visor is standard on all cabs, twin interior sun Visors also being provided. An extractor vent is incorporated in the roof and a 5-kW. fresh-air heating and ventilation unit is supplied. Twin air-operated wipers, twin interim' lights Which illurninate automatically when the doors ate opened . but have overriding switches, and fully adjustable . driving seat and foam-rubber upholstery are also standard equipment..

Above the windscreen there are-,two small, glove pockets, one for the radio, when fitted, and there is a large pocket behind the driver for papers, log book and so forth. Except for the push-button door handles. which are chromium-plated, all the bright ware is of polished anodized aluminium or is stove enamelled. Safety door locks are employed.

Dual Headlamp Layout

Each pair of headlamps is mounted in an aluminium nacelle, combined with which are the side lamps and flashing indicators. The outer headlamps act as long-range driving lamps, whilst the inner lights have dual-filament bulbs. When the lights are dipped the inner lamps remain on and throw a short 'beam which is extended when the lights are switched to main beam.

In the case of the normal-control vehicles, the base for the forward-control cab forms the front-end assembly, whilst the cab superstructure is moved back arid mounted on a special base.

The new range will be represented at the Commercial Motor Show by two forward-control eight-wheelers and a normalcontrol four-wheeler. One of the eight-wheelers will have a single-drive bogie and will be seen on the Guy stand as a tanker, whilst the other will have a double-drive bogie and platform body and will be in the demonstration park. Both chassis will have the. new Gardner 6LX oil engine. The bonneted chassis will be a 15-ft. 9-in,-wheelbase left-hand-drive model with a Rolls-Royce engine,double-reduction axle and fifth-wheel coupling.