Malting the better motor oils of today..

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

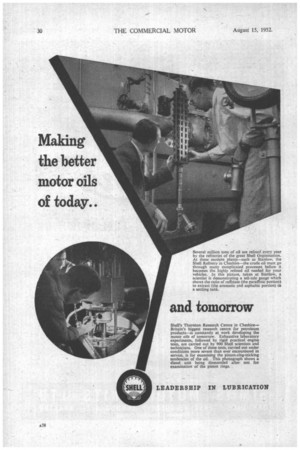

Several million tons of oil are refined every year by the refineries of the great Shell Organisation. At these modem plants—such as Stanlow, the Shell Refinery in Cheshire—the crude oil must go through many complicated processes before it becomes the highly refined oil needed for your vehicles. In this picture, taken at Stanlow, a scientist is demonstrating a tell-tale gauge which shows the ratio of raffinate (the paraffinic portion) to extract (the aromatic and asphaltic portion) in a settling tank.

and tomorrow

Shell's Thornton Research Centre in Cheshire— Britain's biggest research centre for petroleum products—is constantly at work developing the motor out of tomorrow. Exhaustive laboratory experiments, followed by rigid practical engine tests, are carried out by 900 Shell scientists and technicians. One of these tests, carried out under conditions more severe than ever encountered in service, is for examining the piston-ring-sticking tendencies of the oil. This photograph shows a diesel unit being dismantled after test for examination of the piston rings.

The total of payload capacity in the fleet was 81 tons, comprising one at 5 tons, one at 2 tons and one at tons. Dividing the £445 establishment costs by Si, 1 got £52 7s. per annum per ton of payload. That was approximately Li per ton of payload per week, i.e., £5 per week for the 5-tanner, compared with as little as £2 per week fora vehicle in a rural area as calculated in the other article.

That figure shook him so much that he came to see mc about it, and he said: Do you mean to tell me that my establishm!nt costs are so much more than those for the man whose business you were discussing in that article? "

" It seems so," I said, " but, of course, in that case there were eight vehicles and you have-only three and you say your establishment costs do not come down in proportion to the number of vehicles. If they did, your total: instead of being £445, would be about half that amount. In the case of the operator whose business was being discussed In the articles, he had live 5-tonners. You have only three."

" blow about the other vehicles," be asked. " What should 'be allotted to them?" "The 2-tonner, I replied, "will have to be debited with £2 per week and the 11-tonner with £1 10s. per week, and that is sharing the establishment costs among them according to the load they carry."

"I am still worried about having to debit my big vehicles with £5-a-week establishment costs. Surely it would make things better for me if I spread the amount evenly, allowing one-third of £8 10s., that is approximately 0 13s. for each vehicle? "

"11 you were to do that you would The Cement Marketing Co., Ltd., operates this Foden 6/15 eightwheeled tipper, fitted with a Gardner 6L.W. oil engine and a Homalloy, allmetal body. It is used for carrying cement in bulk.

be overloading the expenses debited against the smaller vehicles and giving the 5-tanner too much advantage."

" I understand your method, but I still think that £5 per week is a lot of money to debit. to one sehicle. How do you get at this idea of dividing these costs according to payloads? "

"1 do not 'get at it,' as you put it. It is the procedure that most hauliers use and it is fairly easy to see the logic of it. Take the simplest aspect, that you are trying to work out your costs so as to get at rates on the basis of price per ton. Clearly, if your suggestion that the amount be shared equally among the three vehicles were to be adopted, the rate per ton for the 11-ton vehicle would be increased out of alt proportion.

Proportioning Establishment Costs "Assume that you carry 30 tons per week in the 1+,-toriner and you will do it with £2 13S. per week.-etablish.rnent costs; that means that you have to charge nearly. Is. 9d. per ton on account of establishment costs alone. Now, in the same proportion, the 5-tonner would carry 100 tons per week and the cost per ton on account of establishment costs would be less than 6c1., but. if you work to my method, and would add the correct method, that is to say, allowing £1 10s. per week on the 30-cwt. vehicle, if it carried 30 tons per week the charge per ton on account or establishment costs would be is.

"Likewise with the 5-tanner carrying 100 tons per week, The debit on account of establishment costs is still Is. per ton, io-that all the three vehicles are being treated alike and that, I think, is justification of the method, don't you agree?"

"I do. You are obviously right, but what I am worrying about is how to reduce my establishment costs per vehicle."

"There are two ways, neither of which, unfortunately, appears to be open to you at the moment. One is to reduce the total of your establishment costs and I do not sec how you can do that. The other is to increase the size of your fleet without adding to your establishment costs. I imagine, situated as you are, you will finJ it difficult to get additional licences even if you can find work for the vehicles."

Incidentally, consideration of the figures for establishment costs brings to light another important aspect of the same subject. I have taken the potential loading of the 5-tonner as 100 tons per week and that of the I i-tonner as 30 tons per week. On that basis the proportionment of establishment costs works out at Is. per ton.

2s. a TOn for Overheads

Actually, of course, these tonnages per week are rather high, especially for the class of work in which this operator is engaged. He had no figures which I could use, but it is unlikely that the average will exceed half the quantities named, in which case the incidence of the establishment costs per ton will be double and will amount to 2s. per ton.

This is important, especially in connection with those operators who imagine that establishment costs are a negligible factor in the case of the small man. In this case, as I have said, the figures which f took as a basis for caleulation are the costs quoted to me by the operator and the amount is,. therefore, -beyond dispute. Whether they are high or low,whether they can be reduced or not is beside the point, as in this' particular case I. am dealing with facts.

The point is this: if, for " example, the 5-tonner carries not 100 tons per week but only 40, in that case the establishment costs equal 2s. 6d. per ton of traffic instead of Is. The 11-tonner, on the other hand. may, because its journeys are short and the roads such as to facilitate better speeds, carry 40 tons per week, The incidence of establishment costs in that case is only 9d. per ton, instead of Is.

, Although I have put forward this matter and stated jt to be important, .1 do so with the idea of making the reader, appreciate the potential effect on his charges of these establishment costs. This variation in the effect per ton applies in the case of the standing charges. In the previous article I found that the total of standing charges applying to a 5-tonner on such work as this amounted to £9 per week. If we take that figure and apply it to the case of the 5-tanner carrying 100 tons per week, that is equivalent to Is. 91-d. per ton. On the other hand, if the vehicle carries only 40 tons per week, the standing charges are as much as 4s. 6d. per ton. It should be appreciated that nothing much can be done

about this. The standing charges as set out are practically enalterable. The only way in which their incidence and that of the establishment costs can be reduced is by reorganization of the routine of the vehicle so that it carries more tons per week, and that is something which is 'applicable to almost every business under the sun.