MORE ABOUT BRAKES.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Our Driver and Mechanic Readers Contribute Some Useful Hints.

OTJR LAST little causerie about brakes occurred on this page in the issue of April 4th, when, among other things, we discussed some methods of taking up wear on brake shoes, and, in part, the application of packing pieces to those faces, on the shoes, on which the operating cam takes effect. " W.W.H.B.," of Trowbridge, refers to this discussion and tells us how he overcame an unexpected trouble which arose in connection with the purchase of a second-hand vehicle which, he tells us, he was ordered to bring home.

On taking the machine over he found the rear brakes so badly worn that the earn would turn right over. He slipped a couple of packing pieces of the type referred to in our previous discussion into place and was able not only to get home without further difficulty, but was able to keep running for a month or two afterwards pending the arrival of new shoes. It is significant to note, as showing the amount. of wear which had taken place, that he was able to slip these packing pieces into position without disassembling any part of the chassis. He points out that, in the particular case he has in mind, there was no necessity for having sideflanges on the packing pieces, because the brake cam itself was flanged and prevented lateral movement of those pieces.

He gives a further hint about brakes, • his tip having particular reference to those chassis on which the rear wheels run on floating bushes. When these wear the axles drop and the lower shoe of a pair wears more than the other. Consequently, when fitting packing pieces, it is advisable to try to correct this difference. In some cases he has found a difference.of as much as 3-32nds of an inch as between one and the other.

If the shoes are removed as a preliminary to fitting these packing pieces, the difference can best be ascertained, in the manner shown in the accompanying sketch, by setting the shoes side by side on a surface plate, putting a straightedge along the top of the higher one and noting the distance between the straight-edge and the top of the other.

Another correspondent, hailing from We-st Bromwich, who has omitted to sign his letter, gives rather a useful tip in connection with the set-pins in the brakes of such cars as the Maxwell, Studebaker and Chalmers. He includes two sketches in his letter, both of which are reproduced herewith. In one, the set-pin is shown diagrammatically in its relation to the brake shoe. It will be observed that it. is a plain screw with a deeply slotted head. Now, it often happens, or at least such is the experience of this particular correspondent, that when removing these screws in the orthodox manner by means of a screwdriver, the slot first opens out and then is destroyed altogether owing to the breaking off of one of the ears. His second sketch shows a useful tool whereby the most stubborn of these,shoes,can easily be removed without there being any risk of it being damaged during the process. The material is a piece of steel tubing, orals old box-spanner; which loosely fits the outside of the 'screw. About half an inch from:the end of this tube, a lot 'is cut to accommodatet a piece of 3-32 inch steel. This is ;fitted' into the tubing and riveted over, tummy 'holes being subsequently drilled in the tube at convenient points. Explanation as to the means of using this LS superfluous.

" L.B.," of Halifax, tells us, for our information, that; his district, is one which affords ample opportunity for testing the efficiency of the brakes of any motor vehicle. Drivers in Halifax, it appears, get into a, regular habit of casting an eye over the brakes and brake fittings before setting out. On one occasion he. was taking this simple precautionary measure, and; 'in testing the hand brake, pulled outs'one,of the brake rods from its socket end(' the thread hav_ ing stripped at the point indicated on the accompanying sketch. The thread itself happened,, to be a left-band one, and means were not available for re-screwing the'rod. What he did was to tap out the end of the rod to take asetscrew, and to drill a hole up between the jawseof the socket, large enough to pass a screw of this size. He. was then able, by means of a setscrew inserted between the jaws of the socket, ass•shown in the sketch, and screwed into the end of the rod, to pull the latter into place, the original lock-nut being available to secure it, as the thread was mat stripped all the way along.

" had a brake rod snap in two half a mile from the top of Bury Hill (Arundel), which, is knowns to, most London drivers, who will, therefore, appreciate his desire to put his brakes into order before coming down that declivity. His repair is an excellent example of that capacity which a good driver should possess foemaking use, in emergencies, of -the mistunusual materials. He merely borrowed; as he quaintly puts it, the chain from 'the tailboard of his wagon, bnited.,one end of 'it to the compensator lever and the other to the operating lever. A littleiadjustment to the right and left-hand screw on the main brakerrrod was sufficient. to make this an efficient brake gear. " of,'

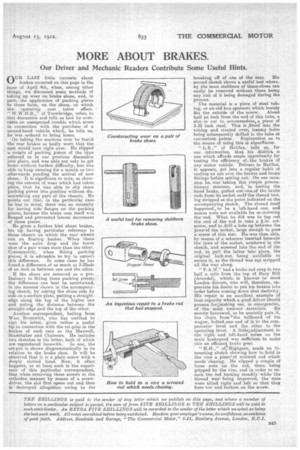

Highgate sends an interesting sketch showing how to hold in the vice a piece of screwed rod which needs chasing. He slipped a couple of loose nuts on the rod,, these being gripped by the vice, and in order to ensure the rod turning steadily while the thread wa.s* being improved, the nuts were tilted right and left so that they, bore ion and bottom on the screw.