NEW ENGINE FOR ATKINSON STEAM LORRY.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

Adoption of New " Uniflow " Valve Arrangement.

IT WAS SOMETHING of a surprise to the readers of TICE COMMERCIAL MOTOR to learn, from the issue dated the '7th September, 1916, that an entirely new model of British-designed steam wagon had made its appearance, in spite of war restrictions, although, of course, they were not so severe two years ago as they are now. When the first description of the new Atkinson six-ton steam wagon was published in this journal, the first of this interesting type had already completed nearly a year of service, We now have to record additional evidence of the enterprise of Messrs. Atkinson and Co., of Preston, in that they have completed the first of a new type of engine intended for embodiment in their standard model wagon so soon as manufacturing circumstances

permit. .

The firm in question has had unusually lengthy experience in connection with the maintenance and repair of this particular class of motor vehicle. Lancashire has, as most of our readers know quite well, always inclined very strongly to the use of heavy self-contained steam-driven units. Indeed, it is well established that there are more steam wagons to the square mile in the southern parts of Lancashire than in any other part of this country.

One does not hear much nowadays of the Leyland steamer (an excellent machine and a great favourite in Lancashire), the factory producing them having for a long while past been entirely concentrated on the well-known War Department type of lorry, now exclusively used by the Royal Air Force. Atkinsons do not disguise the feet that their capacity to design and produce a new type of machine is almost entirely due to their remarkable experience in connection with the repair and maintenance of steamers, especially Leylands and Sentinels; but, of course, also including other makes, such as the Foden. When this first machine was described, the representative of THE COMMERCIAL MOTOR was informed that no fewer than 300 owners depended upon Atkinsons for the maintenance of their Impigons—a fine business connection and one most certainly yielding adequate opportunity for experience of performance and failure alike.

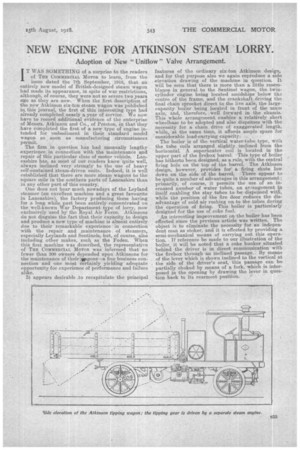

It appears desirable to recapitulate the principal features of the ordinary six-ton Atkinson design, and for that purpose also we again reproduce a side elevation drawing of the machine in question. It will be seen that there is more than a little resemblance in general to the Sentinel wagon, the twincylinder engine being located amidships below the centre of the frame, and the crankshaft driving the final chain sprocket direct to the live axle, the largecapacity boiler being located in front of the main axle, and, therefore, well forward in the chassis. This whole arrangement enables a relatively short wheelbase to be adopted and also dispenses with the necessity for a chain drive of exaggerated length, while, at the same time, it affords ample space for considerable load-carrying capacity.

The boiler is of the vertical water-tube type, with the tube coils arranged slightly inclined from the horizontal. A superheater coil is located in the upper part of the firebax barrel. This type of boiler has hitherto been designed, as a rule, with the central firing hole on the top of the barrel. The Atkinson design, however, provides for a firing chute low down on the side of the ba.rrel. There appear to be quite a number of advantages in this arrangement: primarily, of course, it permits the use of an increased number of water tubes, an arrangement jn itself enabling the stay tubes to be dispensed with, while the position of the fire door reduces the disadvantage of cold air rushing on to the tubes during the operation of firing. This boiler is particularly designed for the use of coke fuel. An interesting improvement on theboiler has been effected since the previous article was written. The object is to eliminate the necessity for an independent man as stoker, and it is effected by providing a semi-mechanical means of carrying out this operation. If reference be made to our illustration of the boiler, it will be noted that a coke bunker situated behind the driver is in direct communication with the firebox through an inclined passage. By means of the lever which is shown inclined to the vertical at the side Of the driver's seat, this passage can be partially choked by means of a fork, which is interposed in the opening by drawing the lever in question back to its rearmost position. In working, then, the procedure is as follows :—Before filling up the bunker with its supply of coal, this lever is . pulled well back, thus closing the passage between the bunker and the firebox. The fire is lighted through the door in front., and coke is gradually admitted by pushing forward the vertical lever ; the latter, when in its foremost position, can be left so until it is necessary either to draw the fire or it is desired to withdraw clinker. In order to distribute the fuel a special design of fire grate is incorpdrated, the bars being secured to a circular-grate which revolves on ball bearings. A horizontal lever, shown close beside the vertical one to which NYe have also referred, is coupled to the spindle of the revolving grate, and to-and-fro motion of the lever revolves the grate, which has the effect of distributing the coal and of accelerating the feed• from the bunker. This device, we understand, is fully covered by patents.

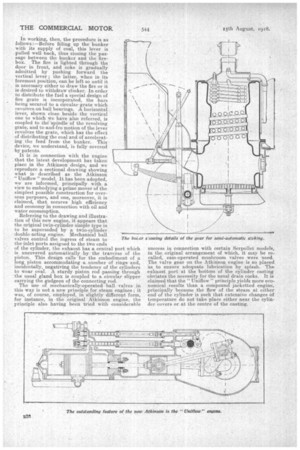

It isin connection with the engine that the latest development has taken place in the Atkinson design, and we reproduce a sectional drawing showing what is described as the Atkinson " Uniflow " model. It has been adopted, we are informed, principally with a view to embodying a prime mover of the simplest possible construction for overseas purposes and one, moreover, it is claimed, that •secures high efficiency and economy in connection with oil and water consumption.

Referring to the drawing and illustration of this new engine, it appears that the original twin-cylinder simple type is to be superseded by a twin-cylinder double-acting engine. Mechanical ball valves control the ingress of steam to the inlet ports assigned to the two ends of the cylinder, the exhaust has a central port which is uncovered automatically by the traverse of the piston. This design calls for the embodiment of a long piston accommodating a .number of ringsand, incidentally, negativing the tendency of the cylinders to wear oval. A. sturdy piston rod passing through the usual gland box is coupled to a circular slipper carrying the gudgeon of the connecting rod. The use of mechanically-operated ball valves in this way is not a new principle for steam engines ; it was, of course, employed, in slightly different form, for instance, in the original Atkinson engine, the principle also having been tried with considerable

success in connection with certain Serpollet models, in the original arrangement of which, it may be recalled, cam-operated mushroom valves were used. The valve gear on the Atkinson engine is so placed as to ensure adequate lubrication by splash. The. exhaust port at the bottom of the cylinder casting obviates the necessity for the usual drain cocks. It is claimed that the " Uniflow " principle yields more economical results than a compound jacketted engine, principally because the flow of the steam at either end of the cylinder is such that extensive changes of temperature do not-take place either near the cylinder covers or at the centre of the casting.