Suggested Design for a Paraffin Engine.

Page 2

If you've noticed an error in this article please click here to report it so we can fix it.

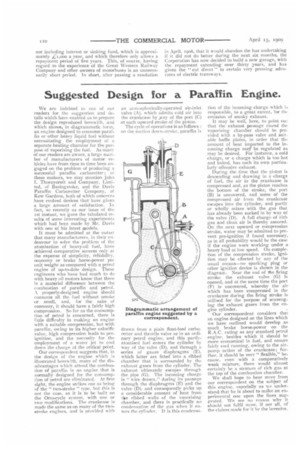

We are indebted to one of our readers for the suggestion and de tails which have enabled us to prepare the design reproduced herewith, and which shows, in diagrammatic form, an engine designed to consume paraf fin or other heavy liquid fuel without necessitating the employment of a separate heating chamber for the purpose of vaporising the fuel. As many of our readers are aware, a large num ber of manufacturers of motor vehicles have from time to time been en gaged on the problem of producing a successful paraffin carburetter; of these makers, we may mention John.

I. Thornyeroft and Company, Limited, of Basingstoke, and the Davis Paraffin Carburetter Company, of Kew Gardens, both of which concerns have evolved devices that have given a large amount of satisfaction. In fact, so recently as our issue of the -1st instant, we gave the tabulated results of some interesting experiments which had been made by Mr. Davis with one of his latest models.

It must be admitted at the outset that many manufacturers, in their endeavour to solve the problem of the atomisation of heavy-oil fuel, have achieved comparative success only at the expense of simplicity, tenability, economy or brake horse-power per unit weight as compared with a petrol engine of up-to-date design. Those engineers who have had much to do with heavy oil motors know that there is a material difference between the combustion of paraffin and petrol. A properly-designed engine should consume all the fuel without smoke or smell, and, for the sake of economy, it should have a fairly high compression. So far as the consumption of petrol is concerned, there is little difficulty in making an engine with a suitable compression, but with paraffin, owing to its higher calorific value, high compression leads to preignition, and the necessity for the employment of a water jet to cool down the charge at the critical point.

Our correspondent suggests that, in the design of the engine which is illustrated herewith, many of the disadvantages which attend the combustion of paraffin in an engine that is normally designed for the consumption of petrol are eliminated. At first sight, the engine strikes one as being of the "two-stroke "type, hut this is not the case, as it is to be built on the Otto-cycle system, with one or two modifications. The crankcase Is made the same as on many of the twostroke engines, and is provided with

an atmospherically-operated air-inlet valve (A), which admits cold air into the crankcase by ,way of the port (C) at each upward stroke of the piston.

The cycle of operations is as follows : on the suction down-stroke, paraffin is

drawn from a plain float-feed carburetter and throttle valve as in an ordinary petrol engine, and this partlyatomised fuel enters the cylinder by way of the valve (D), and through a series of gauze diaphragms (E), which latter are fitted into a ribbed chamber that is surrounded by the exhaust gases from the cylinder. The exhaust ultimately escapes through the pipe (G), The incoming charge is "wire drawn," during its passage through the diaphragms (E) and the valve (D), and consequently picks up a considerable amonnt of heat from tile ribbed walls of the vaporising chamber, and there is practically no condensation of the gas when it enters the cylinder. It is this condensa tion of the incoming charge which is responsible, to a great extent, for the emission of smoky exhaust. It may be well, here, to point out that the exhaust passage round the vaporising chamber should be pro vided with a by-pass valve and suit-able baffle plates, in order that the amount of heat imparted to the in coming charge mai be regulated as may be desired. For instance, a cold charge, or a charge which is too hot and baked, has each its own particularly offensive exhaust.

During the time that the piston is descending and drawing in a charge of fuel, the air in the crankcase is compressed and, as the piston reaches the bottom of the stroke, the port (B) is uncovered, and some of the compressed air from the crankcase escapes into the cylinder, and partly or wholly mixes with the gas that has already been sucked in by way of the valve (D). A full charge of rich gas and clean air is thereby assured. Onthe next upward or compression stroke, water may be admitted to prevent pre-ignition if found necessary, as in all probability would be the case if the engine were working under a heavy load at low speed. On completion of the compression stroke, ignition may be effected by any of the usual means—no sparking plug or other ignition device is shown in the diagram. Near the end of the firing stroke the exhaust valve (G) is opened, and at the same time the port (F) is uncovered, whereby the air which has been compressed in the crankcase during the firing stroke is utilised for the purpose of scavenging the exhaust gases from the en

gine cylinder. • Our correspondent considers that an engine designed on the lines which we have outlined would develop as much brake horse-power on the R.A.C. rating as any standard petrol engine, besides which it should be more economical in fuel, and ensure fairly cool running, owing to the airpump action of the crankcase; further, it should be very" flexible,." because, even with a comparatively weak mixture, there would almost certainly be a stratum of rich gas at the top of the combustion chamber.

We shall hope to hear more from our correspondent on the subject of this engine, especially as we understand that he is about to ma'ke an experimental one upon the lines suggested. We see no reason why it should not fulfil most, if not all, of the claims made for it by the inventor_