The Re-tubing of a Steam Boiler.

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

By " Engineer-in-Charge."

The tubes in locomotive-type boilers, as fitted to steam wagons and tractors, unless they receive the necessary amount of attention, are liable to cause a great deal of trouble chiefly due to the severe duties which such boilers have frequently to perform, and also to a great extent to the amount of ignorance displayed by many drivers in their endeavours to remedy difficulties. On more than one occasion I have seen tapered iron plugs driven so hard into the ends of tubes, in order to stop their leaking, that the tube-plate between two adjacent tubes was cracked, whilst some traction engines on the road at the present time have had many a bushel of barley meal inside their boilers for the purpose of stopping leaky tubes. In this class of boiler, owing to the water space's being so very restricted, many tubes may, to all appearances, be sound, but it is advisable to withdraw them periodically to verify their condition. If not the whole of them, at least every alternate tube should be drawn to facilitate the search for tubes which show signs of " wasting " by the action of the fire. The top row is liable to suffer more than the others, and especially so should the water happen to get low at any time— particularly when ascending hills. On an " up " g-ra

dient, the glass may show " full," but it is impossible to tell exactly how high the water is above the top of the glass, or whether the smoke-box end of the tubes are bare.

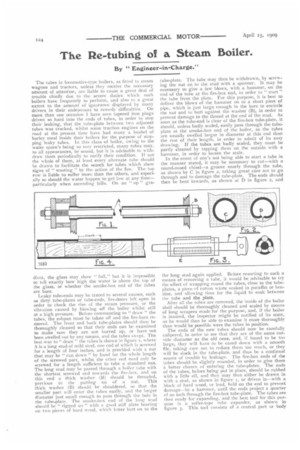

Leaky tube-ends may be traced to several causes, such as dirty tube-plates or tube-ends, fire-doors left open in order to check the rise of the steam pressure, or the vibration caused by blowing off the boiler whilst still at a high pressure. Before commencing to " draw " the tubes, the ashpan must be taken off and the fire-bars removed. The front and hack tube-plates should then be thoroughly cleaned so that their ends can be examined to make sure they are not burred up, or have not been swelled out by any means, and the tubes swept. The best way to" draw " the tubes is shown in figure t, where A is a long stud of mild steel, one end of which is screwed for a length of four inches, and is provided with a nut that may be " run clown " by hand for the whole length of the screwed part, whilst the other end need only be screwed for a length sufficient to take a standard nut. The long stud may he passed through a boiler tube with the shortest screwed end towards the fire-box, and on this end a thick washer (B) should be threaded, previous to the putting on of a nut. This thick washer (B) should be shouldered, so that the smaller part will enter the tubes easily, and the larger diameter just small enough to pass through the hole in the tube-plate. The smoke-box end of the long stud should be "rigged 110 " with a good stiff plate bearing on two pieces of hard wood, which latter butt on to the tube-plate. The tube may then be withdrawn, by screwing the nut on to the stud with a spanner. It may be necessary to give a few blows, with a hammer, on the end of the tube at the fire-box end, in order to " start " the tube from the plate. For this purpose, it is best to deliver the blows of the hammer on to a short piece of pipe, which is just large enough in the bore to encircle the nut and to butt against the washer (II), in order to prevent damage to the thread at the end of the stud. As soon as the tube-end is clear of the fire-box tube-plate, it should, unless badly scaled, easily pass through the tubeplate at the smoke-box end of the boiler, as the tubes are usually swelled larger in diameter at this end than the rest of their length, in order to admit of its easy drawing. If the tubes are badly scaled, they must be partly cleaned by tapping them on the outside with a hammer, in order to loosen the scale.

In the event of one's not being able to start a tube in the manner stated, it may be necessary to cut—with a round-nosed chisel—a groove nearly through the tube, as shown by C in figure 2, taking great care not to go through and to damage the tube-plate. The ends should then be bent inwards, as shown at D in figure 2, and the long stud again applied. Before resorting to such a means of removing a tube, it would be advisable to try the effect of wrapping round the tubes, close to the tubeplates, a piece of cotton waste soaked in paraffin or benzine, and allowing time for the liquid to soak between the tube and the plate.

After all the tubes are removed, the inside of the boiler shell should be thoroughly cleaned and scaled by means of long scrapers made for the purpose, and, if the boiler is insured, the inspector might be notified of its state, as he would then be able to examine it more thoroughly than would be possible were the tubes in position.

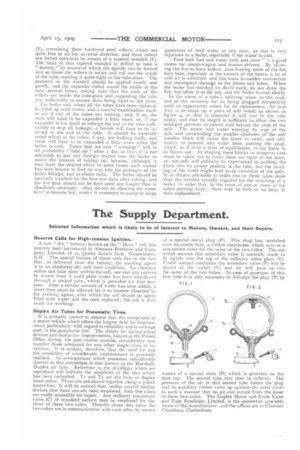

The ends of the new tubes should now be carefully calipered, in order to see that they are of the same outside diameter as the old ones, and, if found to be too large, they will have to be eased down with a smooth file, taking care not to reduce them too much, or they will be slack in the tube-plate, and thus be a continual source of trouble by leakage. The fire-box ends of the tubes should be slightly rounded, in order to give them a better chance of entering the tube-plates. The ends of the tubes, before being put in place, should be rubbed with a little oil, and they may then either be drawn in with a stud, as shown in figure 1, or driven in—with a block of hard wood, or lead, held on the end to prevent damage—by a hammer, until the ends project a quarter of an inch through the fire-box tube-plate. The tubes are then ready for expanding, and the best tool for this purpose is a roller-type tube expander, as shown in figure 3. This tool consists of a central part or body

(E), containing three hardened steel rollers, which are quite free in all but an axial direction, and these rollers are forced outwards by means of a tapered mandril (F). The head of this tapered mandril is drilled to take a " tommy," by means of which the spindle can be turned and so cause the rollers to rotate and roll out the inside of the tube, making it quite tight in the tube-plate. The pressure on the mandril should be applied evenly and gently, and the expander rolled round the inside of the tube several times, taking care that the ends of the rollers are inside the tube-plate and expanding the tube just sufficiently to ensure their being tight in the plate. The boiler can, when all the tubes have been replaced, be filled up with water, and a careful examination made to see if any of the tubes are leaking, and, if so, the ends will have to be expanded a little more, or, if the expander is too small to enlarge the end of the tube sufficiently to stop all leakage, a ferrule will have to be inserted in the end of the tube. It should be carefully noted which of the tubes, if any, are leaking badly, and these will have to be expanded a little more when the boiler is cold. Tubes that are only " weeping " will in all probability " take up" after a day or two; it is not advisable to put any foreign matter into the boiler to assist the process of taking up, because, although it max' have the desired effect in some cases, such matter has been known to find its way into the passages of the boiler fittings, and to choke them. The boiler should be carefully watched for the first few days after tubing, and the fire door should not be kept open any longer than is absolUtely necessary. Also, do not, by allowing the water level to become low, render it necessary to pump in large quantities of feed water at any time, as this is very injurious to a boiler, especially if the water is cold.

Feed both fuel and water little and often " is a good motto for steam-wagon and tractor drivers. By allowing the fire to burn hollow, thus leaving some of the fire bars bare, especially at the corners of the boxes, a lot of cold air is admitted, and this leads to sudden contraction and consequent damage to the plates and tubes. When the boiler has finished its day's work, do not draw the fire, but allow it to die out, and the boiler to cool slowly.

In the event of a tube's splitting when on the road, and of the necessity for its being plugged temporarily until an opportunity arises for its replacement, the best way is to shape up a piece of soft wood, as shown in figure 4, so that in diameter it will just fit the tube easily, and that its length is sufficient to allow the two enlarged portions to extend well beyond the ends of the split. The steam and water entering by way of the split and surrounding the smaller diameter of the soft wooden block will cause the latter to swell, and ultimately to prevent any water from passing the plug, which, as it is in a state of equilibrium, is not liable to be blown out. in shaping these blocks or stoppers, care must be taken not to make them too tight at the start, or, not only will difficulty he experienced in pushing the block into its proper position in the tube, but the swelling of the wood might lead to an extension of the split. It is always advisable to order two or three tubes more than the number actually required for the re-tubing of a boiler, in order that, in the event of one or more of the tubes proving faulty, there may be little or no delay in their replacement.