YORK

Page 114

Page 117

If you've noticed an error in this article please click here to report it so we can fix it.

design for the Continent

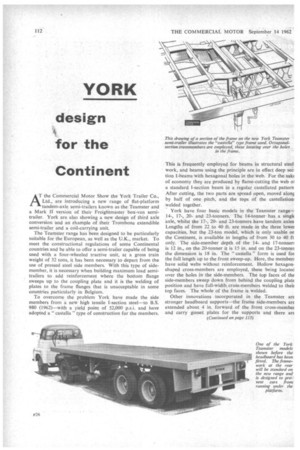

AT the Commercial Motor Show the York Trailer Co., Ltd., are introducing a new range of flat-platform tandem-axle semi-trailers known as the Teamster and a Mark IT version of their Freightmaster box-van semitrailer. York are also showing a new design of third axle conversion and an example of their Trombone extendible semi-trailer and a coil-carrying unit.

The Teamster range has been designed to be particularly suitable for the European, as well as the U.K., market. To meet the constructional regulations of some Continental countries and be able to offer a semi-trailer capable of being used with a four-wheeled tractive unit, at a gross train weight of 32 tons, it has been necessary to depart from the use of pressed steel side members. With this type of sidemember, it is necessary when building maximum load semitrailers to add reinforcement where the bottom flange sweeps up to the coupling plate and it is the welding of plates to the frame flanges that is unacceptable in some countries particularly in Belgium.

To overcome the problem York have made the side members from a new high tensile I-section steel—to B.S. 980 (1962)—with a yield point of 52,000 p.s.i. and have adopted a " castella " type of construction for the members.

This is frequently employed for beams in structural steel work, and beams using the principle are in effect deep sec tion I-beams with hexagonal holes in the web. For the sak( of economy they are produced by flame-cutting the web 01 a standard 1-section beam in a regular castellated pattern After cutting, the two parts are spread open, moved .alonf by half of one pitch, and the tops of the castellation; welded together.

York have four basic models in the Teamster range-7 14-, 17-, 20and 23-tonners. The 14-tower has a singh axle, whilst the 17-, 20and 23-tonners have tandem axles Lengths of from 22 to 40 ft. are made in the three 'owei capacities, but the 23-ton model, which is only usable or the Continent, is available in lengths of from 30 to 40 ft only. The side-member depth of the 14and 17-toriner is 12 in., on the 20-tonner it is 15 in. and on the 23-tonne] the dimension is 18 in. The " eastella " form is used fen the full length up to the front sweep-up. Here, the memberi have solid webs without reinforcement. Hollow hexagon shaped cross-members are employed, these -being located over the holes in the side-members. The top faces of the side-members sweep down from behind the coupling plate position and have full-width,cross-members welded to theil top faces. • The whole of the frame is welded.

Other innovations incorporated in the Teamster are stronger headboard supports—the frame side-members arc extended about 4 in. forward of the front cross-membei and carry gusset plates for the supports and there .art o examples of the urt. One will have t and be constructed to s. It is. one of six being built rallers. The other example is for e exhibited without a floor so that the tion can be seen.

9-1eration on this exhibit is from a two-line air jt:,,tem through Shur-Brake chambers made by

'en „') • opnufactuning and Sales Co. of America. These tnventional brake diaphragm units but, in place

Sc" •Sragm body on the pressure side of the unit, Shaving a spring-loaded piston and C, pressure supplied direct from the trailer

o the piston -back against the spring and the 9a -r ike operation is applied between the plunger oc. 0 raga]. -When. the pressure in the reservoir t,)

p t'Etain level the spring, acting through its °).„.•,,'Idiaphragrn, applies the brakes.

o main advantages of the Shur-Brake. One s the handbrake to be dispensed with -the

Crp uated when the trailer is to be parked and that the outfit cannot be moved until the r is recharged to release the spring.

master Mark II differs-from the earlier model of ways although the basic design and the

an, odels offered is unchanged. The main differences re ii methods of making the sub-frame and mounting

Fie rut, irtg gear. All the sub-frame. cross-bearers arc now. •

in deep and located at 12 in intervals instead of being mixture of 4and 8-in, deep bearers located at varying positions. The running gear—this can be single or tandem xle or twin -oscillating axle—in the latest design is mounted in a separate sub-frame instead of being fitted directly on o the main frame. The running gear. sub-frame incorportes two heavy full-width main cross-members which locate in the outside of the body.

Changes to the body design on the Freightmaster Mark It nclude the use of a new light alloy extrusion for the roof op corner member. This is designed so that the one-piece ight alloy roof panel can be riveted in place outside the clad area (the roof is bonded to the cross-sticks) and so prevent leakage. of rain water into the •body•past the-rivets. The extrusion also incorporates a channel for electrical wiring which is covered by a moulded plastics strip. Changes have also been made to the rear doors. These are now of light-alloy faced 'chip board and double sealed at the top, bottorn and closing edges by a new rubber moulding strip.

There will be two of the latest Freightmasters on the York stand. One will be a tandem-axle 20-toriner for B.R.S. Continental, the other a single-axle .12-toriner for Golden Wonder Crisps. The 'latter will have a one-piece 0.625-in ply floor and incorporate Cary-Laminaire suspension. A third example will be on the Demonstration Park. This will be a single-axle model for Express -Dairy and the interior is fitted out with roller tracks (in two layers) to facilitate the loading and unloading of Stillages. The rear is closed by a full height Dover roller .shutter to the latest design and a Burtonwood tail lift is. fitted.

" Also on. the Demonstration Park there will be a Trombone, tandem-axle extendible semi-trailer-and a tandem-axle coil-carrier.

On the York stand in the Accessory and Equipment Section will be seen a new design of third-axle conversion which it is estimated will be about £45. cheaper than the existing York design. This is different from. conventional designs in that the added axle is mounted in front of the existing driving axle on the vehicle. To Clear the propeller shaft the axle tube is dropped in the centre. A four-leafspring suspension layout is used. 'The front eyes of the springs are slipper-mounted in brackets cinAhe chassis sidemembers, whilst the rear -eyes of the springs on each Side are connected by a fabricated beam pivoted on the frame above the driving axle. The beam has arms of unequal length so that 55 per cent. of the load on the bogie is taken by the driving axle.

It is also possible with the design to mount the additional axle behind the existing axle as in conventional conversions. In this 'case a straight tubular axle is fitted.

On their second stand York will also be displaying their existing third axle conversion. This will be of a bogie using an A.E.C, driving axleand will incorporate the York air load transfer system. A Bedford TK with this form of conversion will' be on the Demonstration Park.