How will this new development affect your business ?

Page 6

If you've noticed an error in this article please click here to report it so we can fix it.

The flour industry provides a firstclass opportunity for you to expand your business. All the leading biscuit manufacturers and many of the big bread bakeries are using, or will use, flour in bulk. This means that millers will have to deliver their flour in bulk. Now that the industry is changing over to the new system, You have an excellent chance of offering your services to the millers.

SAVINGS

What is the reason for the new development? Bulk flour handling and storage make big savings over old-fashioned sack methods. Although the initial cost of a bulk handling installation is high, capital expenditure is regained in a very short time. The labour costs in bulk handling and storing systems are approximately one seventh of those in sack installations. Every year scores of thousands of pounds Worth of flour are lost on bakery floors and between the fibres of hessian bags. There are no losses when flour is hatidled and stored in bulk.

Is it any wonder that the bakers are turning to bulk flour?

HYGIENE

Here is another reason for the change-over bulk flour is clean flour. It contains no sack hairs or impurities. It is completely protected from the weather and contamination in transit and store. The baker appreciates the advantages of clean flour. He tells his customers about it. In this way bulk flour sends up his sales.

SIMON WAGON

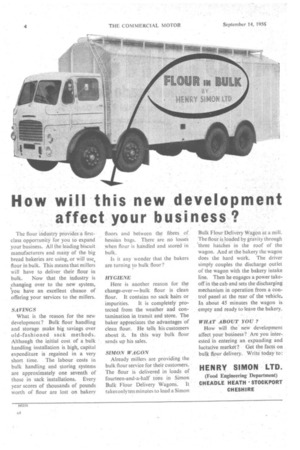

Already millers are providing the bulk flour service for their customers. The flour is delivered in loads of fourteen-and-a-half ACM in Simon Bulk Flour Delivery Wagons. It takes only ten minutes to load a Simon Bulk Flour Delivery Wagon at a mill. The flour is loaded by gravity through 'three hatches in the roof of the wagon. And at the bakery the wagon does the hard work. The driver simply couples the discharge outlet of the wagon with the bakery intake line. Then he engages a power takeoff in the cab and sets the discharging mechanism in operation from a control panel at the rear of the vehicle. In about 45 minutes the wagon is empty and ready to leave the bakery.

WHAT ABOUT YOU?

How will the new development affect your business? Are you interested in entering an expanding and lucrative market? Get the facts on bulk flour delivery. Write today to:

HENRY SIMON LTD.

(Food Engineering Department) CHEADLE HEATH • STOCKPORT CHESHIRE