HINTS ON MAINTENANCE.

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

Refitting Steam-wagon Chains. A Fiat Improvement. Modifying a Dennis Water Pump. Notes on Crossley Engine Lubrication.

Refitting Heavy Driving Chains.

The weight of a driving chain for such a vehicle as a 5-ton or 6-ton steam wagon may be as much as 3 cwt. and contain about 100 links; consequently, unless the mechanic knows his job, the refitting of a new or repaired chain becomes an exhausting and even dangerous procedure.

When fitting a new chain to a vehicle, first of all count the number of links in the old chain, measure the adjusting rods and have the new chain made sufficiently long to permit it to be adjusted up to working conditions and still allow for further adjustment after use. See that the nut which secures the ends of the chain is on the correct side, which is invariably the outer side.

To assemble the chain, bring it directly under the back-axle chain sprocket, fasten a piece of stout rope through the third link from each end, then stand on the chassis above the back axle and lift one end of the chain over the sprocket, fastening the rope to a crossmember. Carry out a similar procedure with the other end of the chain, pulling this over the driving sprocket, but first putting the engine into neutral so that the driving sprocket can easily be rotated. When once the chain is in its approximate position the engine gears can be engaged to keep it there.

Various ways for actually bringing the chain ends together to insert the bolt have been described in The Commercial Motor, and perhaps the best of these is to lace the rope around the rollers of the ends in such a manner that these and the rope form blocks and tackle. so that by pulling one end of the rope tightening of the chain can easily be accomplished. The rope is laced from the third link on one end to the second on the other and then from this back to the first link, and

SO OD.

Improving the Chain Adjusters of the Type 18P Fiat.

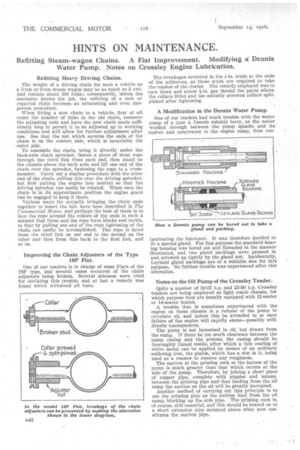

One of our readers is in charge of some Fiats of the 18P type, and several cases occurred of the chain adjusters being broken. Several schemes were tried for obviating this trouble, and at last a remedy was found which withstood all tests. The breakages occurred in the j-in. studs at the ends of the adjusters, as these studs are required to take the tension of the chains. The remedy employed was to turn down and screw 1-iD, gas thread the parts where the collars fitted and use suitably screwed collars splitpinned after tightening.

A Modification in the Dennis Water Pump.

One of our readers had much trouble with the water pump of a type A Dennis subsidy lorry, as the water worked through between the pump spindle and its bushes and penetrated to the engine sump, thus con taminating the lubricant. It was therefore decided to fit a special gland. For this purpose the standard bearing housing was bored out and threaded in the manner illustrated, and two gland packings were pressed in and screwed up tightly by the gland nut. Incidentally, Leyland gland packings are of a suitable size for this purpose. No further trouble was experienced after this alteration.

Notes on the Oil Pump of the Crossley Tender.

Quite a number of 20-25 h.p. and 25-30 h.p. Crossley tenders are being employed as light coach chassis, for which purpose they are usually equipped with 12-seater or 14-seater bodies.

A trouble that is sometimes experienced with the engine on these chassis is a refusal of the pump to circulate oil, and unless this be attended to at once failure of the engine will rapidly ensue—possibly with drastic consequences.

The pump is not immersed in oil, but draws from the sump. If there be too much clearance between the pump casing and the pinions, the casing should be thoroughly tinned inside, after which a thin coating of white metal can be applied by means of an ordinary soldering iron, the pinion, which has a slot in it, being used as a reamer to remove any roughness.

The suction at the priming cock at the bottom of the pump is much greater than that which occurs at the side of the pump. Therefore, by joining a short piece of copper pipe, complete with nipples and unions, between the priming pipe and that leading from the oil sump the suction on the oil will be greatly increased.

Another method of carrying out this principle is to use the priming pipe as the suction lead from the oil sump, blocking up the side pipe. The priming cock is, of course, still essential, and this should be brazed on to a short extension pipe mounted above what now constitutes the suction pipe.