FROM CHAIN DE E TO LIVE AXLE.

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

VOR some years past the Albion Motor Car Co., Ltd.,

Scotstoun, Glasgow, have been experimenting with a number of live-axle chatsis with load-carrying capecities-above that of the 2-ton type, which has proved Se remarkably' successful, and up to 4 tons. These vehicles have been in use as vans and, consequently, valuable experience has been gained with them.

One of the aims has been to develop a live-axle 3-tormer which will not sacrifice reliability, will he as cheap to run as, and weigh not more than, the 3-ton chain-driven model which has for so long been a feature of the Albion programme, and this has resulted in the production of the new model 27, which is subdivided Into two types, the L.F., equipped with solid tyres, and the L.H., equipped with pneumatic tyres. The _basic type may be taken as the solid-tyred one, and it is chiefly with this that we will deal, pointing out later those differences which have been embodied in the mpfiel running on pneumatic tyres.

The chassis is constructed to carry a net load of 3 tons, allowing 16 cwt. for the body, which is the same as is given on the chain-driven model. The standard wheelbase is 13 ft. and the approximate chassis weight 49 cwt. It is seldom that a chassis of medium-load capacity can be constructed • to weigh much, if anything, less than the load for which it is designed, and it is only by well-thought-out design, the employment of first-class materials and the cutting out of small weaknesses which showed themselves in the experimental models that this light weight has been achieved in combination with a high factor of safety and reliability.

Excellent consumption figures have been obtained on petrol and oil. On the road tests an average of 9 m.p.g. has been given, and this with the vehicle slightly overloaded. It must be remembered, however, that this applies to continuous running and must not, naturally, be expected on work involving a large number of stops. The oil consumption of about 1,500 m.p.g. Is, of course, subject to the same comments.

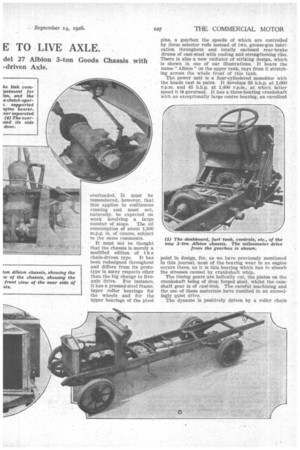

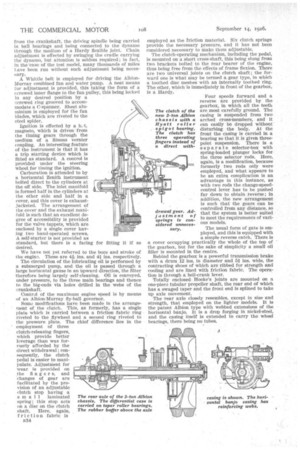

It must not be thought that the chassis is merely a modified edition of th chain-driven type. It has been redesigned throughout and differs from its prototype in many respects other than the big change to live-. axle drive. For instance, it has a pressed-steel frame, taper roller bearings for the wheels and for the upper bearings of the pivot pins, a gearbox the speeds of which are controlled by three selector rods instead of two, grease-gun lubrication throughout and totally enclosed rear-brake drums of cast-steel with cooling and strengthening ribs. There is also a new radiator of striking design, which is shown in one of our illustrations. It bears the name " Albion " on the upper tank, rays from it stretching across the whole front of this tank.

The power unit is a four-cylindered monobloc with the heads cast in pairs. It develops 33 b.h.p. at 1,000 r.p.m. and 45 b.h.p. at 1,400 r.p.m., at which latter speed it is governed. It has a three-bearing crankshaft with an exceptionally large centre bearing, an excellent point in design, for, as we have previously mentioned in this journal, most of the bearing wear in an engine occurs there, as it is this, bearing which has to absorb the stresses caused by crankshaft whip.

The timing gears are helically cut, the pinion on the crankshaft being of drop forged steel, whilst the camshaft gear is of cast-iron. The careful machining and the use of these materials have resulted in an exceedingly quiet drive.

The dynamo is positively driven by a roller chain from the crankshaft, the driving spindle being carried in ball bearings and being connected to the dynamo through the medium of a Hardy flexible joint. Chain adjustment is effected by swinging the cradle carrying the dynamo, but attention is seldom required ; in fact, in the'case of the test model, many thousands of miles have been run without such adjustment being necessary.

A Whittle belt is employed for driving the AlbionMurray combined fan and water pump. A neat means for adjustment is provided, this taking the form of a ccrewed inner flange to the fan pulley, this being locked in any desired position by a ecrewed ring grooved to accommodate a C-spanner. Sheet aluminium is employed fof the fan blades, which are riveted to the steel spider.

Ignition is effected by a h.-t. magneto, which is driven 'from the timing gears through the medium of a Simms vernier coupling. An interesting feature of the instrument is that it has a trip starting device which is fitted as standard. A control is provided under the steering wheel for timing the ignition.

Carburation is attended to by a horizontal Zenith instrument bolted direct to the cylinders at the off side. The inlet manifold is formed half in the cylinders at the other side and half in a cover, and this cover is exhaustjacketed. The arrangement of the cover and the exhaust manifold is such that an excellent degree of accessibility is provided for the valve tappets, which are enclosed by a single cover having two hand-operated screws. A self-starter is not provided as standard, but there is a facing for fitting it if so desired.

We have not yet referred to the bore and stroke of the engin2. These are 4fg ins. and 41 ins. respectively.

The circulation of the lubricating oil is performed by a submerged pump, and the oil is passed through a large horizontal gauze in an Upward direction, the filter therefore being largely self-cleaning. Oil is conveyed, under pressure, to the three main bearings and thence to the big-ends via holes drilled in the webs of the crankshaft.

Control of the maximum engine speed is by means of an Albion-Murray fly-ball governor.

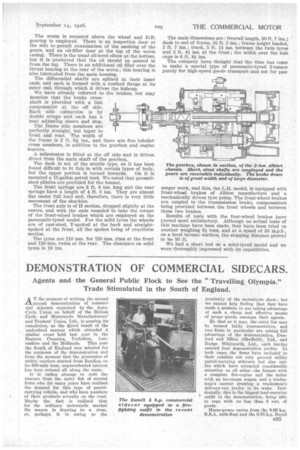

534 employed as the friction material. Six clutch springs provide the necessary pressure, and it has not been considered necessary to make them adjustable.

The clutch-operating mechanism, including the pedal, is mounted on a short cross-shaft, this being slung from two brackets bolted to the rear bearer of the engine, thus being free from the effects of frame flexion. There are two universal joints on the clutch shaft ; the forward one is what may be termed a gear type, in which a toothed disc meshes with an internally toothed ring. The other, which is immediately in front of the gearbox, is a Hardy.

Four speeds forward and a reverse are provided by the gearbox, in which all the teeth are most carefully ground. The casing is suspended from two arched cross-members, and it can easily be dropped without disturbing the body. At the front the casing is carried in a bearing so that it is given threepoint suspension. There is a separate selector-box with spring-loaded plunger locks for the three selector rods. Here, again, is a modification, because formerly two rods only were employed, and what appears to be an extra complication is an advantage in this instance, as with two rods the change-speedcontrol lever has to be pushed far down to obtain reverse ; in addition, the new arrangement is such that the gears can be controlled from any distance, so that the system is better suited to meet the requirements of various models.

The usual form of gate is employed, and this is equipped with a simple reverse catch. There is a cover occupying practically the whole of the top of the gearbox, but for the sake of simplicity a small oil filler is mounted in the centre.

Behind the gearbox is a powerful transmission brake with a drum 12 ins, in diameter and 51 ins, wide, the contracting shoes of which are ribbed for strength and cooling and are lined with friction fabric. The operation is through a bell-crank lever.

Totally enclosed‘ Hooke's joints are mounted on one-pieca tubular propeller shaft, the rear end of which has a swaged taper and the front end is splined to take up axle movement.

The rear axle closely resembles, except in size and strength, that employed on the lighter models. It is the patent Albion type with webbed extensions of the horizontal banjo. It is a drop forging in nickel-steel, and the casing itself is extended to carry the wheel bearings, there being no tubes.

sary.

The worm is mounted above the wheel and D.B. gearing is employed. There is an inspection door at the side to-permit examination of the meshing of the gears, and an oil-filler door at the top of the worni casing. There is the usual oil-level elbow at the bottom, but it is preferred that the oil should be poured in from the top. There is an additional oil filler over the thrust bearing at the rear of the worm ; this bearing is also lubricated from the main housing.

The differential shafts are splined at their inner .ends, and each is formed with a toothed flange at its outer end, through which it drives the hubcap.

We have already referred to the brakes, but may mention that the brake crossshaft is provided with a link compensator at the off side. Each side connection is by double straps and each has a neat adjusting sleeve and stop.

The frame side members are perfectly straight, but taper to front and rear. The width of the frame is 2 ft. 81 ins., and there are five tubular cross members, in addition to the gearbox and engine bearers.

A mileometer is fitted at the off side and is driven direct from the main shaft of the gearbox.

The dash Is not of the scuttle type, as it has been found difficult to fit this in with certain types of body, but the upper portion is turned inwards. On it is mounted a 15-gallon petrol tank. We noted that pressedsteel plinths are provided for the bonnet.

The front springs are 3 ft. 6 ins, long and the rear springs have a length of 4 ft. 6 ins. They are almost flat under full load and, therefore, there is very little movement of the shackles.

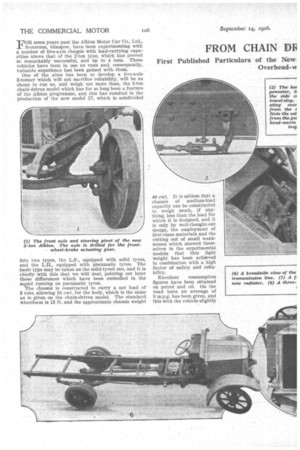

The front axle is of H section, dropped slightly at the centre, and with the ends rounded to take the torque of the front-wheel brakes which are employed on the pneumatic-tyred model. For the solid tyres the wheels are of cast-steel, Y-spoked at the back and straightspoked at the front, all the spokes being of cruciform section.

The tyres are 110 mm. for 720 mm. rims at the front and.120 ram. twins at the rear. The clearance on solid tyres is 10 ins. The main dimensions are : Overall length, 20 ft. 7 ins.; dash to end of frame, 16 ft. 5 ins.; frame height loaded, 2 ft. 7 ins.; track, 5 ft. 11 ins, between the twin tyres and 5 ft. 41 ins, at the front ; the width over the hub caps is 6 ft. 8i The company have thought that the time has come to make a special type of pneumatic-tyred 3-tonner purely for high-speed goods transport and not for pas senger work, and this, the L.H. model, is equipped with front-wheel brakes of Albion manufacture and a mechanically driven tyre pump. The front-wheel brakes are coupled to the transmission brake, compensators • being provided between the front wheels and between these two brakes.

Results of tests with the four-wheel brakes have proved most satisfactory. Although no actual tests of this machine have been made, they have been tried in another weighing 61 tons, and at a speed of 34 m.p.h , on a level tarmac surface, the stopping distance proved to be 50 ft.

We had a short test on a solid-tyred model and we were thoroughly impressed with its capabilities.