IIVAST; NOT ANT NOT

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

When new opportunities knock at the door of a family haulage business, they are often treated with suspicion, occasionally strangled on the doormat, or sent on their way at the merest hint of a risk.

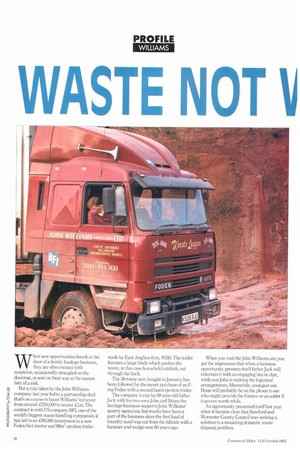

But a risk taken by the John Williams company last year led to a partnership deal that's on course to boost Williams' turnover from around £250,000 to nearer Lim. The contract is with US company BFI, one of the world's biggest waste handling companies: it has led to an £80,000 investment in a new Foden 6x4 tractor and 90m3 ejection trailer

made by East Anglian firm, \VBS. The trailer features a large blade which pushes the waste, in this case household rubbish, out through the back.

The 38-tonne unit, bought in January, has been followed by the recent purchase of an Freg Foden with a second-hand ejection trailer.

The company is run by 69-year-old father Jack with his two sons John and Brian; the haulage business supports John Williams' quarry operation, but trucks have been a part of the business since the first load of foundry sand was cut from the hillside with a hammer and wedge over 60 years ago. When you visit the John Williams site you get the impression that when a business opportunity presents itself father Jack will entertain it with an engaging line in chat, while son John is making the logistical arrangements. Meanwhile, youngest son Brian will probably be on the phone to see who might provide the finance or an outlet if it proves worth while.

An opportunity presented itself last year when it became clear that Hereford and Worcester County Council was seeking a solution to a mounting domestic waste disposal problem. Proposals for a waste tip, involving another operator and waste disposal operator Cleanaway, had been rejected. "The council tip is almost exhausted," says Brian Williams. "Nobody has planning permission to tip, so refuse collection lorries would have to travel a long way and they are not the quickest of movers. This is where a transfer station comes into its own. The company found itself in the right place at the right time. It had already been involved in removing skips of building waste but although it has tipping permission at the quarry, the expense of developing a waste operation on its own had already prompted the company to talk to companies like Cleanaway and BFI about the possibilities of financial investment."

After the tip idea had failed, BFI asked if John Williams would be interested in getting involved with a domestic waste contract from Hereford and Worcester. "I said to BFI: have got planning permission and you've got the resources, knowledge and a large waste tip in Birmingham. Build us a transfer station and we'll run it as a joint venture," says Brian Williams.

BFI came up with a a50,000 investment and in January the waste transfer station was opened at the Williams' site, with a fiveyear domestic waste handling contract.

The waste comes in on refuse collection vehicles, then reloaded on to waste loggers and trunked to BFI's tip at Packington in Birmingham. As John Williams is a registered waste carrier and an operator of a transfer station, the administration side of the operation for them is relatively simple: the company does not have to deal with a transfer station run by a third party for example. However, the risk factor for the company and its management is considerably increased by operating on both sides of the waste business fence.

LICENSING

Complicated waste licensing regulations are open to wide interpretations and even a minor infringement in the Williams fleet under the carriage of waste regulations could endanger the licence for the transfer station,

and vice-versa.

In addition, the company is responsible for ensuring that any waste accepted conforms with the description on the consignment note. Accepting the wrong form of waste could have serious consequences and liabilities.

However, careful management is not the only disincentive for rogue waste carriers at this particular station: "We are not cheap here. Those sort of people do not want to know about expensive tips," he says.

The site is licensed to accept 600 tonnes of waste per day, including waste from other operators and the general public, and the operation has not been slow to capitalise on other opportunities. The decline in the number of UK foundries has reduced the demand for moulding sand: expanding the product base over the past three years has maintained the haulage operation.

For example, by the introduction of dry and wet screening of the sands, a variety of building products can be offered as well as the building stone which it buys in. Rather than run a large expensive fleet, however, John Williams prefers to use a fleet of regular sub-contractors.

These provide an important source of eight-leggers, which complement the company's own four-and six-wheel rigids and artics. The company's workshop offer maintenance and refinishing facilities to contractors as well as its own-account fleet and its supporting cast of plant equipment including site excavators, loading shovels and crushers.

Diversification remains the name of the ,Tame—skip hire is the latest venture—and Jack explains that the company has always been prepared to exploit an idea.

SYNTHETIC

For example, you won't find a description of cinetic sand in any geological dictionary "Back in the 1930s. the Americans came up with a synthetic moulding sand that could be used in foundries," he explains. "Our business was supplying foundries with moulding sand too. My father realised he couldn't call our quarried sand synthetic, so he called it emetic instead. It seemed to work well enough."

Jack is leaving more and more of the haulage side of the business to his sons but they have no intention of altering his hands-on approach to management. Although Jack no longer takes trucks on to the road he still drives on-site and emergency consignments of building sand are just as likely to be delivered by John or Brian as by one of the regular drivers or subcontractors. Personal involvement is just as strong on the quarry side, which is regularly manned by managers as well as employees. Jack says that just as the original US connection provided a springboard to development in the past, this latest US connection through 1-WI has helped make a new opening for the future.

In about ten years the 40-acre site will be exhausted and an alternative use will be sought. One possibility is a truckstop and service station which, thanks to the close proximity of the M42 and the M5, might do very nicely A new orbital route may be built along the side of the quarry; if this goes ahead the company will explore the idea of a leisure complex with a golf course and lakes for water sports. Such a major building project would also put John Williams (Cinetic Sand) back in the right place at the right time. E by Steve McQueen