A New Small Oil Engine

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

The Victor Horizontally Opposed Twincylindered I 0-11.h.p Engine, Designed Primarily for Marine Work, Has a Strong Road-transport Interest

LTEIOUGH it is designed primarily for marine use, the latest product of the CoventryVictor Motor Co., Ltd., Cox Street, Coventry, shows that it is quite possible to build, with fair success, a really small compression-ignition unit. An interesting feature is that the fuel pump, the injector nozzles and the combustion chambers are all desigued and made by the engine manufacturer.

In common with many previous Coventry-Victor engines, this compression-ignition unit has two horizontally opposed cylinders. The bore and stroke dimensions are 75 mm. and 78 mm, respectively, so that the capacity is 688 c.c., or roughly one-third litre per cylinder. The Treasury rating is approximately 7 h.p. Complete with a water-circulating pnmp, and other accessories, including a particularly heavy flywheel, the engine weighs 160 lb., and is stated to develop 10 b.h.p. at 2,000 r.p.m.

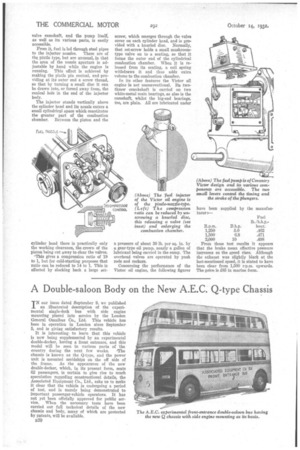

In the Victor fuel pump, provision is made for the manual control both of the injection timing and of the stroke of the punip plungers. These are moved by cams which are shaped so as to give a suitably rapid rise and fall of pressure at the beginning and the end of the injection period. Between each cam and . its plunger there are two levers, one , above the other and pivoted at opposite ends. A roller is located between them.

The lower lever, which bears on the cam, is pivoted to a lug on a shaft which can be turned by band through a small angle. This has the effect, of course, of advancing or retarding the cam follower in relation to the cam, and, therefore, of performing the same function for the injection period.

In order to vary the stroke of the plunger, the roller already mentioned is moved along the cam-follower lever.

When it is near the pivot it obviously receives less motion than when it is near the cam end Of that lever. This motion is imparted to the second lever placed above the roller, and is passed on to the pump plunger by means of a short tappet. The return stroke of the plunger is effected, in the usual way, by means of a light coil spring. The fuel-pump unit is driven from the end of the valve camshaft, and the pump itself, as well as its various parts, is easily accessible.

Prom it, fuel is led through steel pipes to the injector nozzles. These are of the pintle type, but are unusual, in that the area of the nozzle aperture is adjustable by hand while the engine is running. This effect is achieved by making the pintk pin conical, and providing at its outer end a screw thread, so that by turning a small disc it can be drawn into, or forced away from, the conical hole in the end of the injector body.

The injector stands vertically above the cylinder head and its nozzle enters a small cylindrical space which constitutes the greater part of the combustion chamber. Between the piston and the cylinder head there is practically only the working clearance, the crown of the piston being cut away to clear the valves.

This gives a compression ratio of 10 to 1, but for cold-starting purposes that ratio can be reduced to 14 to 1. This is effected by slacking back a large set

screw, which emerges through the valve cover on each cylinder head, and is provided with a knurled disc. Normally, that set-screw holds a small mushroomtype valve on to a seating, so that it forms the outer end of the cylindrical combustion chamber. When it is released from its seating, a coil spring withdraws it and thus adds extra volume to the combustion chamber.

In its other features the Victor oil engine is not unconventional. Its twothrow crankshaft is carried on two white-metal main bearings, as also is the camshaft, whilst the big-end bearings, too, are plain. All are lubricated under a pressure of about 30 lb. per sq. in. by a gear-type oil pump, nearly a gallon of lubricant being carried in the sump. The overhead valves are operated by push rods and rockers.

Concerning the performance of the Victor oil engine, the following figures

(Above) The fuel pump is of Coventry Victor design and its various components are accessible. The two small levers control the timing and the stroke of the plungers.

have been supplied by the manufacturer :— Fuel lb./b.h.p.

It.p.m. B.h.p. hour.

1,250 5.0 .462 1,500 6.8 .471 2,000 10 .498 From these test results it appears that the brake mean effective pressure increases as the speed rises. Although the exhaust was slightly black at the last-mentioned speed, it is stated to have been clear from 1,500 r.-p.m. upwards. The price is 185 in marine form.