A 2.ton Tipper of Robust Design.

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

MHERE are many spheres of activity

in which the tipping wagon gives more efficient and economical service than the chassis fitted with an ordinary goods-carrying body. The chief recommendation of the tipping body is, perhaps, the fact that it enables certain classes of load to be discharged with the utmost ease, wHereas with an ordinary body considerable manual labour would be required in order to ensure that the whole of the contents of the body were removed This is particularly true of such loose loads as sand, gravel and road metal, and where a .high angle of tip can be obtained it is possible to secure ready discharge of loads which have a tendency to cling to the body sides.

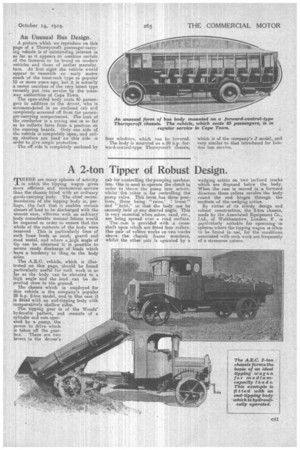

The A.E.C. vehicle, which is illustrated on this page, should be found particularly useful for such work in so far as the body can be elevated to a high angle and the load can be deposited close to the ground.

The chassis which is employed for this vehicle is the company's popular 28 h.p. 2-ton model, and in this case it is fitted with an end-tipping body with comparatively shallow sides. The tipping gear is of the Woods' hydraulic pattern, and consists of a cylinder and ram operated by a Rump, the power to drive which is taken off the gearbox. There are two levers in the driver's cab for controlling the pumping mechanism. One is used to operate the clutch in order to throw the pump into action, whilst the other is for controlling the pump valve, This lever has three positions, these being "raise," lower" and "hold," so that the body can be securely held at any desired angle. This is very essential when ashes, sand, etc., are being spread over a road surface. The ram is provided with a crossshaft upon which are fitted four rollers. One pair of rollers works on two tracks above the chassis frame members, whilst the other pair is operated by a

wedging actioa on two inclined tracks which are disposed below the body. When the ram is moved in a forward direction these rollers revolve the body round the end hinges through the medium of the wedging action.

By virtue of its sturdy design and robust construction, the 2-ton chassis, made by the Associated Equipment Co., Ltd., of Walthamstow, London, E, is particularly suitable for operating -in spheres where the tipping wagon is often to be found in use, for the conditions associated with such work are frequently of a strenuous nature.