There are leftand right-hand-drive versions of the R type. The

Page 48

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

left-hand-drive model has a standard vacuum-servo-hydraulic brake system operating on all wheels, whereas the right-hand-drive chassis, conforming to Ministry of Supply requirements, has compressedair assistance for the hydraulic brakes, with connections at the rear for operating brakes on a trailer.

Clayton Dewandre compressed-air equipment is specified, the dimensions of the operating cylinder being such that the overall braking efficiency is approximately equal to that of the vacuum-servo system. The compressor is attached horizontally to the frame below the floor at the passenger side of the cab, and is beltdriven from the crankshaft. Exhaust-Valve inserts in the cylinder head have been eliminated, the valve seats being formed in the parent metal, and free-release exhaust-valve rotators have been installed.

The front propeller shaft obstructs the normal gearbox power-take-off flange, so provision is made for a full power-take-off drive from the transfer box. Certain models are available with rear-mounted winches driven from the transfer box. Drive to the rear axle is direct in the high ratio and front-wheel drive is automatically engaged when the 2-to-1 reduction is selected. The rear-axle drive shafts arc thus protected against overloading because the torque is increased through the transfer-box reduction, but is shared by the front-wheel drive.

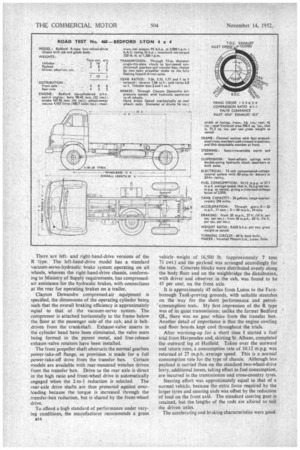

To afford a high standard of performance under varying conditions, the manufacturer recommends a gross vehicle weight of 16,500 lb. (approximately 7 tons 71 cwt.) and the payload was arranged accordingly for the tests. Concrete blocks were distributed evenly along the body floor and on the weighbridge the distribution, with driver and observer in the cab, was found to be 45 per cent, on the front axle.

It is approximately 45 miles from Luton to the Farnborough Tank-proving grounds, with suitable stretches on the way for the short performance and petrolconsumption tests. My first impression of the R type was of its quiet transmission; unlike the former Bedford QL, there was no gear whine from the transfer box. Another detail of importance is that the engine cowling and floor boards kept cool throughout the trials.

After warming-up for a short time I started a fuel trial from Harpenden and, skirting St. Albans, completed the outward leg at Hatfield. Taken over the outward and return runs, a consumption rate of 10.12 m.p.g. was returned at 27 m.p.h. average speed. This is a normal consumption rate for the type of chassis. Although less payload is carried than on the standard two-wheel-drive lorry, additional losses, taking effect in fuel consumption, are incurred in the transmission and cross-country tyres.

Steering effort was approximately equal to that of a normal vehicle, because the extra force required by the larger tyres and steering ends was offset by the reduction of load on the front axle. The standard steering gear is retained, but the lengths of the rods are altered to suit the driven axles.

The accelerating and braking characteristics were good. Thirty m.p.h. was reached from a standing start in 24 secs., and stopping distances of 27 ft. from 20 m.p.h., and 60 ft. from 30 m.p.h. were recorded on the return journey from Farnborough after immersion in mud. This was the first time I had encountered the air-pressureassisted hydraulic braking system, which appears to have a notably short time delay.

In the conversion of the Bedford system, the normal hydraulic master and wheel cylinders are used, with vacuum or compressed-air assistance for the pedal. The brake master cylinder incorporates two pistons operating in tandem, so that the rear brakes will still be effective should a leak occur in the front system, or vice versa. As a further safeguard, the coupling system between the air operating and brake master cylinders provides for direct connection if the air supply fails.

Tyre pressures were lowered fo, cross-country work before tackling the gruelling suspension-test circuit at Farnborough. Granite slabs of different heights are laid in regular patterns, causing the wheels to bounce violently. At .times the vehicle rides smoothly until the pattern of the course finds the spring periodicity Point, when a tight grip is required on the steering wheel to overcome the violent reaction. I did not have much trouble in keeping the Bedford on the track, because the steering gear is designed to prevent the road shock from being transmitted to the steering wheel The Bedford was driven over this circuit for three miles without loosening any parts of the body or chassis and although there must have been extensive twisting• and bending of the frame, _there was no indication Of slipping out of gear. It is not unusual on this course for the gear or transfer-box levers to move into a neutral position, indicating insufficient pressure on the selector locks or misalignment of bearings between the levers and boxes.

Freak Hill-climbing

Then followed the climbing tests up loose-surfaced slopes of known gradient. The 1-in-3.2_ slope was almost a second-gear climb and the 1-in-3 section of the escarpment, with a top layer of pebbles, was also taken quite comfortably. I then headed the chassis towards the 1-in-2.78 gradient and with the engine surging on governed speed, the Bedford started well, but wheelspin developed within a few yards of the top, and, as the wheels dug deeper into the pebbles, the engine laboured to stalling point.

After carefully reversing to the starting point, I made a second attempt and the chassis roared up the hill, bumped over the Previous ruts and came to a stop a yard nearer the top. After further trials, gaining about a yard at each attempt, it at last completed the climb successfully and, having once hardened a track, it repeated the performance without further trouble. This was only the second time that I had climbed the slope on a 3-4-ton vehicle.

There is a steeper loose-pebble climb of 1 in 2.43, and although the Bedford Made several gallant efforts to reach the top, every attempt ended with the tyres biting through the surface, and eventually the engine stalled when they gripped on firm ground several inches below. This did not indicate the maximum tractive effort, because the I-in-21 concrete slope was scaled at full engine speed, and a stop-start test staged halfway up the incline. The hand brake held the Bedford stationary on the slope.

After climbing tests came 15 miles of milling around the well-furrowed plain and hills, where continued testing of tracked vehicles has ground the surface to a thick layer of fine dust. With frequent gear changes required on this type of terrain, I felt that the gear lever would be easier to manipulate had it been cranked more towards the engine. After a few miles there was a noticeably increased movement on the transfer-box lever between accelerating and overrunning. The cause was found to be loose nuts on the box. This was the only mechanical adjustment made during the tests.

Ample Ground Clearance My opinion of the chassis rose again as it climbed the banks and rode the furrowed ground, and although the spring bump rubbers suffered at times, there was no metallic contact to indicate insufficient clearance at any ,point. The cab kept cool during prolonged pulling in low gear and with a day reading of 55 degrees F., the water temperature remained between 155 and 162 degrees F.

Oil temperatures recorded at the end of an hour's work indicated the front and rear axles to be 122 and 118 degrees F. respectively and the transfer box 142 degrees F. The. shape qf the dip-stick guide prevented a glass stick thermometer from being used in the engine base.

The chassis was then headed towards the ponds, where the water is 18-20 ins.,deep; below the surface is thick silt on clay. On single-axle drive the Bedford developed wheelspin, but with front-wheel drive engaged, it pulled itself clear. There were occasions when the spare-wheel carrier grounded as the front of the chassis rode clear of hummocks, but the petrol tank on the opposite side remained unscathed.

Mud and water oozed from the wheels and brake drums as the vehicle was driven on hard ground. While they were draining, the chassis was inspected for damage or loose parts and the tyres were inflated in readiness for further road work. The inflation gear is excellent, the large compressor and reservoir saving a great deal of time. A driver will pay more attention to tyre pressures when inflation is easy and rapid.

After the brakes had recovered from immersion in mud and water, their efficiency returned to normal. With a system designed for a 10-ton gross vehicle weight, the wheels can be locked on full brake application when a 3-ton load is carried, such as in the four-wheel-drive version.

The vehicle can exceed 50 m.p.h., and can travel at speed without steering or braking difficulties.

I consider the designers have been, most successful in building a high-performance four-wheel-drive chassis at low cost, using parts common to the conventional road vehicle.