PUTTING TH1 HT where it iE Leeded

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

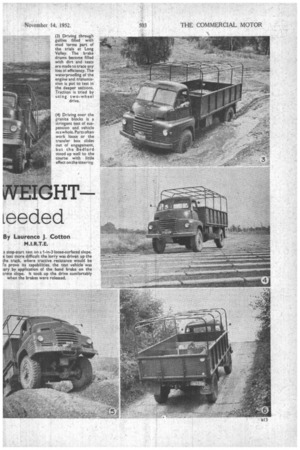

INHERITING the large petrol engine and gearbox of the 7-ton chassis, the Bedford R-type forward-control four-wheel-drive model, a successor to the QL, has exceptional cross-country performance When carrying a nominal 3-31--ton payload, The R type. tackled the, Farnborough gradients with 'zeal, taking the 1-in-2,1 concrete slope in good style, but it met its master in the smooth round pebbles on . the steepest loose-surfaced gradient.

Performance on steep hills is improved by the weight distribution, almost half the total "load being imposed on the front tyres. When climbing gradients, a great deal of 'weight is transferred to the rear axle, and should there be insufficient load on the front tyres, the vehicle is likely to dig in at the front on a loose surface, thus causing wheel-spin. At the same time, too much weight at the front is a disadvantage when crossing soft, windblown sand. Neither of these eventualities is likely to befall the Bedford unless it is grossly overloaded or the weight is poorly distributed.

Ministry Specification The four-wheel-drive chassis has many parts in common with the S-type 7-ton 13-ft. 6-in.-wheelbase model, with the addition of a transfer box and drive to the front wheels. It is one of the cross-country vehicles built to Ministry of Supply requirements.

The main differences between the R type and the conventional 7-tonner include shortened frame side members at the rear, the placing of one cross-member to support the transfer box and the use of large single tyres on all wheels. In fitting 11.00-20-in, cross-country tyres, but keeping the turning circle down to 60-ft. diameter, it has been necessary to increase the normal track at the front, and to use a rear axle 6 ins, wider to preserve the alignment of the front and rear wheels. This arrangement is beneficial when driving over loose soil, because the front tyres pack the ground firmly for the rear tyres and losses through tractive resistance are reduced. . . . . In common with the rear axle, the front-axle drive incorporates a. standard hypoid gear, but the drive assembly is turned to bring the pinion above the centre of the axle. Fully enclosed Tracta universal joints are employed in the front-wheel drive. A feature of the front suspension is a wind-up plate at the rear of the main leaf, to prevent the axle nose from lifting excessively under maximum braking or reverse driving torque conditions.

Because of the difference in axle weight with a 3-ton load, and the exceptional work imposed on the suspension by cross-country operation, a new design of spring is fitted to both axles, but double-acting hydraulic shock absorbers are provided to assist when travelling over rough ground. With the increased rear track, a new axle case, having longer driving shafts and associated components, has been provided.

. The front-axle housing is a fabricated assembly comprising a malleable cast-iron differential carrier with pressed-in tubular extensions. One spring seat is welded to the top of the tubular extension, but the left-hand seat is cast integrally with the differential carrier. A heavier-section cover is fitted over the front face to safeguard the hypoid gear. Adequate clearance is provided between the front-axle drive and the base of the engine, and this arrangement. together with the larger lyres, has made the frame 7 ins, higher than that of the normal two-wheel-drive chassis.