METAL CUTTING AND _

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

AUTOGENOOS WELDING.

The Oxy-acetylene and Oxy-hydrogen Processes.

W[THIN THE PAST few years a valuable tool, unique in its characteristic, has been developed for cutting, shaping, and welding metals. This is the oxy-acetylene " torch," which now is so weal advanced that it bids fair to displace other emergency cutting and welding means, to a large extent. The oxy-acetylene process had its inception in France, the first experimenter being Mons. Edmund Fouche, of Paris, *ho begun his work on it in Mt.

The principle of the oxy-acetylene torch or burner is essentially the same as that of the oxy-hydrogen blow-pipe, which has been used for many years for generating intense heat. But though the oxy-hydrogen flame is intensely hot, the flame produced by the oxy-acetylene torch is so much hotter that the two are not in the same class. The temperature produced by the oxy-hydrogen flame is rated by authorities at about 4000 deg, Paha, while that of the oxy-acetylene flame is estimated at about 6300 deg. Fahr. Not only is the flame of acetylene much hotter than hydrogen, but the number of R.T.U. per cubic ft. is about five times as great, being as 330 to 1600. Hence both the intensity and amount of heat is greatly increased in the flame of the oxy-acetylene torch. A comparison between the two instruments has been aptly put as like that of "a finely-pointed tool and a blunt instrument."

A few of the purposes for which cutting and welding toaches are -commonly used are as follow : —For cutting steel wreckage, steel piling, steel beams in structural work, risers from steel casting, open through steel plates, etc. : for welding seams, reclaim

00 lag cracked castings, filling in blow-holes in castings, adding metal to worn surfaces tosecure original thickness, welding piping without removal, filling holes -which have been incorrectly located, replacing broken gear teeth by welding in new material, sealing riveted seams to secure tight joints without caulking.

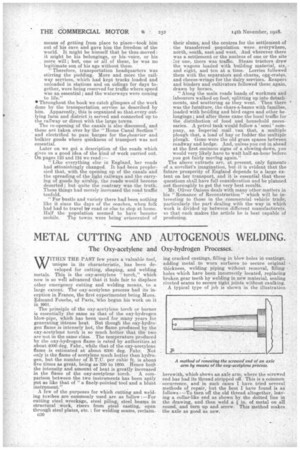

A typical type of job is shown in the illustration

herewith, which shows an axle arm, where the screwed end has had its thread stripped off. This is a common occurrence, and in such cases I have tried several methods of repair, but the best I have found is as follows :—To turn off the old thread altogether, leaving a collar-like end as shown by the dotted line in the drawing, and then weld a a in. of metal on all round, and turn up and screw. This method makes the axle as good as new.