r - 7 Vehicle Wanicciamx0) (0) by Preceptor

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

ispension, 2

E STEEL leaf spring, first used horse drawn vehicles is )bably still the most popular re despite the advantages imed for alternatives which re been more recently eloped.

)ne of the characteristics of a f spring is the damping effect rich occurs because of the ;tion between the leaves as w slide over one another len the spring is deflected. To ertain extent this is beneficial t too much friction between a leaves will cause wear and ise and give a hard ride. In the early days of motoring a springs were sprayed with netrating oil, at the time of ch routine service, but on odern vehicles the leaves are ten separated by rubber buttons or by some other means or have interleaves of a low friction material.

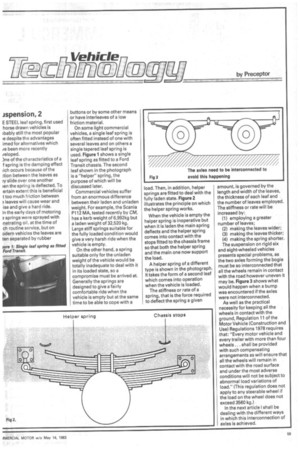

On some light commercial vehicles, a single leaf spring is often fitted instead of one with several leaves and on others a single tapered leaf spring is used. Figure 1 shows a single leaf spring as fitted to a Ford Transit chassis. The second leaf shown in the photograph is a "helper" spring, the purpose of which will be discussed later.

Commercial vehicles suffer from an enormous difference between their laden and unladen weight. For example, the Scania P112 MA, tested recently by CM, has a kerb weight of 6,992kg but a laden weight of 32,520 kg. Large stiff springs suitable for the fully loaded condition would give a very harsh ride when the vehicle is empty.

On the other hand, a spring suitable only for the unladen weight of the vehicle would be totally inadequate to deal with it in its loaded state, so a compromise must be arrived at. Generally the springs are designed to give a fairly comfortable ride when the vehicle is empty but at the same time to be able to cope with a load. Then, in addition, helper springs are fitted to deal with the fully laden state. Figure 2 illustrates the principle on which the helper spring works.

When the vehicle is empty the helper spring is inoperative but when it is laden the main spring deflects and the helper spring comes into contact with the stops fitted to the chassis frame so that both the helper spring and the main one now support the load.

A helper spring of a different type is shown in the photograph. It takes the form of a second leaf which comes into operation when the vehicle is loaded.

The stiffness or rate of a spring, that is the force required to deflect the spring a given amount, is governed by the length and width of the leaves, the thickness of each leaf and the number of leaves employed. The stiffness or rate will be increased by: (1) employing a greater number of leaves; (2) making the leaves wider; (3) making the leaves thicker; (4) making the spring shorter.

The suspension on rigid six and eight-wheeled vehicles presents special problems, as the two axles forming the bogie must be so interconnected that all the wheels remain in contact with the road however uneven it may be. Figure 3 shows what would happen when a bump was encountered if the axles were not interconnected.

As well as the practical necessity for keeping all the wheels in contact with the ground, Regulation 11 of the Motor Vehicle (Construction and Use) Regulations 1978 requires that: "Every motor vehicle and every trailer with more than four wheels ... shall be provided with such compensating arrangements as will ensure that all the wheels will remain in contact with the road surface and under the most adverse conditions will not be subject to abnormal load variations of load." (This regulation does not apply to any steerable wheel if the load on the wheel does not exceed 3560 kg.) In the next article I shall be dealing with the different ways in which this interconnection of axles is achieved.