TRANSMISSIONS

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

y Pa u I B rockington, MI MechE

k The role of lutonnatics

• ONLY a fully-automatic insmission as cheap and efficient as the AF infinitely-variable belt-drive Varioatic could be applied to a heavy vehicle Id it had an acceptable service life, the msport world would be a much better ace to live in.

To the driver of a light car or van, the iriomatie is a boon in terms of improved .celeration and ease of driving in traffic. If efficient transmission with comparable taracteristics were developed for heavy tmmercial vehicles it would offer far eater advantages, with gains in fuel msumption and performance in all xrating conditions.

Of special importance, it could be tntrolled by a little black box to give what most needed for economical running and w wear and tear of the engine. Used in injunction with a two-stage throttle pedal, could. for example, enable a vehicle to )erate at road speeds above 40 mph at a instant 70/80 per cent throttle opening id minimum engine rpm. If the load were creased by a gradient or head wind, speed ould he maintained by increasing the ansmission ratio to give a lower gear and gher engine rpm. A further progressive crease in power up to full power and )propriate variation of the ratio would be )tained by movement of the pedal against creased pressure past the limiting position -the first stage.

It would be necessary to operate with 1/80 per cent throttle opening when avelling at 40 mph or higher speeds, and igine speed would be reduced by more an 50 per cent in a typical case if the ;hide were running light, compared with unit the output of which was controlled in Le normal way by the throttle. The average licieney of the engine would be very ibstantially improved and reduction in fuel msumption of at least 25 per cent should 0 obtainable in applications involving a fair [0 portion of light-load operation. A trottle-limiting roadspeed governor could 0 incorporated in the black-box system to bvi ate overspeeding in favourable xiditions.

While the infinitely-variable transmission ith a high efficiency is an ideal that has een awaiting commercial fulfilment for half century or more (the Variomatie is an xception). detailed improvements in the esign of hydrostatic infinitely-variable ump /motor transmissions might make the system a viable proposition overnight for commercial vehicle applications.

And it might be possible to produce a belt drive of the Variomatic type with rubber or steel chain belts that could cater for high outputs by transmitting a major percentage of the torque through epicyclic gearing as is done in the Giles hydrostatic system. The Perbury infinitely-variable roller system based on the Hayes principle could well be revitalized by development work of the National Research Development Corporation. Perhaps surprisingly, many operators have become "automatic minded" in the past year or two. The high wages paid to drivers in this country combined with shorter hours have increased the rewards of getting the best out of the driver, as well as the machine, and in practice this includes safeguarding the machine against misuse by the driver.

Escalating running costs have increased the need for higher productivity and many operators are looking at automatic transmission with renewed interest as a possible means of raising productivity.

The comment by the engineer of a company operating fleets of vehicles on the African continent that a fully-automatic transmission would enable vehicles to be driven more expertly to give improved reliability and a longer life, has been reiterated with equal emphasis by a number of operators in the UK. But few haulage operators anywhere are willing to pay the extra thousand pounds (plus) that an automatic costs except in the case of a dump truck mainly employed on site work. A torque converter /epicyclic transmission, such as the Allison, can raise the productivity of a dump truck very considerably, despite the fact that an engine of increased output is normally used to offset additional losses in the transmission.

Because facilitating and controlling the work of the driver of a stage-carriage psv is more important to productivity than easing the job of the lorry driver, employing a semior fully-automatic gearbox is often justified on the score of overall costs despite the higher first cost, while passenger safety, comfort and convenience are a concomitant consideration that favours the use of an automatic.

Keeping in mind the prospect of automatic transmissions being applied more extensively to heavy haulage vehicles to improve their productivity (road tests of artics equipped with a semi-automatic will be mentioned later on that give substance to this prospect) it is pertinent to review the current policy and practices of London Transport with regard to transmissions, notably the use of fully-automatic gearboxes with overriding manual control.

A gearbox that enables ratio changes to be made on full throttle offers obvious advantages in terms of acceleration time compared with one which requires that the load be removed by closing the throttle during a change. The only type of mechanical gearbox that could provide this facility satisfactorily is an epicyclic unit in which changes are made by the application of a brake band or plate clutch and in which engagement on full throttle involves "a clutching-in" phase that might be assumed to cause rapid wear of the friction material.

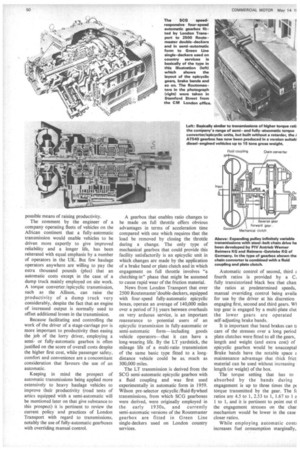

News from London Transport that over 2500 Routemasteedouble-deckers, equipped with four-speed fully-automatic epicyclic boxes, operate an average of 140,000 miles over a period of 3f years between overhauls on very arduous service, is an important reassurance to potential users of an epicyclic transmission in fully-automatic or semi-automatic form—including goods vehicle operators—that it can have a long-wearing life. By the LT yardstick, the mileage life of a multi-ratio transmission of the same basic type fitted to a longdistance vehicle could be as. much as 300,000 miles.

The LT transmission is derived from the SC G semi-automatic epicyclic gearbox with a fluid coupling and was first used experimentally in automatic form in 1959. Wilson pre-selector epicyclic /fluid-flywheel transmissions, from which SCG gearboxes were derived, were originally employed in the early 1930s, and currently semi-automatic versions of the Routemaster gearbox are fitted in Green Line single-deckers used on London country services. Automatic control of second, third g fourth ratios is provided by a fully transistorized black box that chan the ratios at predetermined speeds, manual overriding control being availa for use by the driver at his discretion engaging first, second and third gears. WI top gear is engaged by a multi-plate clut the lower gears are operated self-adjusting brake bands.

It is important that band brakes can tl care of the stresses over a long period plate clutches were fitted to all the gears, length and weight (and extra cost) of epicyclic gearbox would be unacceptal Brake bands have the notable space k maintenance advantage that thick frict material can be used without increasing length (or weight) of the box.

The torque setting that has to absorbed by the bands during engagement is up to three times the pi torque transmitted by the gear. The fi ratios are 4.5 to 1, 2.53 to 1, 1.67 to 1 s 1 to 1, and it is pertinent to point out ti the engagement stresses on the char mechanism would be lower in the case closer ratios.

While employing automatic coot increases fuel consumption marginally, ords a greater overall economy of ration, reduces driver fatigue and 'vides a high standard of gear changing !spective of driver skill. Moreover, it ;ures that vehicle ride is jerk-free, which essential when standing passengers are Tied, and it eliminates high shock stresses the system, A German Voith 501 fully-automatic que-converter /epicyclic gearbox has been ni experimentally by London Transport 24 years, and it is notable that the nverter lock-up clutch gives an provement in fuel consumption.

The performance of the Voith has been bored to comply with the performance of ; standard box, as far as possible, but its

.que multiplication is in excess of mirements. Torsional vibrations have

an experienced in the transmission when celerating on overrun at around 10 mph d at idling. This is a general problem ten lock up is used and has yet to be mpletely overcome. The lack of automatic justment of the engagement bands ;reases maintenance.

In a general comment on torque nverters, LT observes that a converter is rmally heavier than a planetary unterpart, and while it gives good Inability it is somewhat noisier in • eration.

The GK N /SRM fully-automatic gearbox also being evaluated by LT, and certain xlifications are in hand to give a ogressive acceleration throughout the nge. Use is not made of the on-off braking Forded by the torque converter because a rate of application is too severe for indee buses. Auxiliary braking would be ceptable if it were progressive.

A splitter version of the SCG five-speed mi-automatic epicyclic gearbox with a ;k-up fluid coupling provides 10 speeds th a ratio range of 7.25 to 1, to 0.77 to and has been successfully applied to a imber of heavy haulage vehicles.

A semi-automatic is probably preferable a fully-automatic version in applications a trunking vehicle if the vehicle is in the Inds of an experienced driver because osing the throttle instantaneously when tanges are being made reduces the igagement torque of the brake bands. And experienced driver might well be able to crease mpg at least marginally by dicious use of the gears. Dissatisfied users ' the transmission might have been ttisfied customers if driver training had aen more thorough.

An SCG 10-speed splitter gearbox was .ted in the Leyland Freightliner tractive it of a Leyland /Scammell 30-ton-gross

tic, the road test report of which was Wished in CM, December 13 1968, and in

re AEC Mandator tractive unit of an EC /Doden 32-ton artic that was the tbject of an earlier road test reported in

M, May 31, 1968. The air-operated brakes ands of the transmission are controlled by small lever in a six-position gate and the litter ratios are selected by a switch on the nob.

While the Leyland 690 turbocharged tgine of the Freightliner produced 240 bhp t 2200 rpm and a torque of 650 lb ft at 1400 rpm, the AEC 800 Series V8 diesel of the Mandator developed 241 bhp at 2600 rpm and a torque of 580 lb ft at 1400 rpm.

It was noted in the report of the Leyland /Scammell artic that the transmission enabled the gradients of the 731-mile test route to be climbed in a shorter time than would have been possible with a manual box (which should be taken into consideration when judging the fuel consumption) and that, of greater importance, a normal running speed could be reached more quickly after a climb because it was possible to make virtually instantaneous ratio changes. Consumption varied between 5.1 mpg and 7.25 mpg, the overall figure being 6.21 mpg.

In the report of the AEC /Boden artic, it was observed that the splitter gearing gave easier changing than would have been provided by a two-speed axle. The ratio range and steps of the transmissions in the two applications were identical. On a similar test route the V8-engined outfit had an overall fuel consumption of 5.95 mpg.

In the first two articles in this series it was shown that it was generally expedient to cater for the current needs of heavy vehicle manufacturers by ringing the changes with standard and well-proven main units as is exemplified in the case of automatics by the splitter version • of the SCG five-speed gearbox. If automatic control could be applied to a standard type of stepped gearbox at a reasonable cost the potential of the system would be enhanced by the suitability of the transmission for application to a variety of vehicles in its basic form.

Electronic control

The observations made by Mr E. Riddle, chief designer of Scammell Lorries, in his paper on manual gearboxes for trucks at the Drive Line Conference in Jersey in April 1970, could be of very special significance. In his paper, Mr Riddle indicated that recent advances in electronic control and sensing might enable automatic control to be applied to range-change gearboxes with up to 20 ratios. And later he told CM that the system might offer a relatively cheap way of producing a lightweight fully-automatic gearbox despite the apparent complexity of the control units. Apparently, the system would change gears according to speed and load by operation of the clutch, throttle and change mechanism in a way that would be practised by a highly skilled driver. Presumably, the gearbox could be manually controlled if the system failed.

Torque converter /epicyclic systems are in a special category. Expensive, relatively heavy and wasteful of fuel in typical applications, they have proven merits in terms of startability, long life and endurance and their use reduces shock stresses in the drive line. But although their cost will remain high detailed improvements may well give a worthwhile gain in efficiency that will win new customers.

It is notable that one of the latest fully-automatic torque-converter transmissions to be developed, the Scania H500, is fitted to the Metro-Scania single-deck o-m-o buses in the Leicester City Transport and Newport Corporation fleets. This transmission is of the split-torque type in which part of the torque is transmitted through mechanical gearing as well as the converter during a hydro-mechanical stage; at higher speeds and lower loads, all the torque is transmitted mechanically.

This is also the basic principle of the Voith Diwa Automatic transmission and may be compared with the well-proven Allison semiand fully-automatic transmissions, the heavy-duty versions of which incorporate an hydraulic retarder, and the GKN /SRM which has yet to be produced commercially and which also affords overrun braking, in this case by utilizing the converter system. As mentioned earlier, the Voith and the SRM are being evaluated in service by London Transport.

While transmissions for heavier vehicles have been the theme of this series, it is appropriate to mention that the Borg-Warner 35 fully-automatic torque converter transmission has been selectively applied to light-delivery vans over the years with highly favourable results in terms of reduced maintenance and in some cases improved fuel consumption.

The Comment by an operator that he employed salesmen rather than drivers to drive his vans and that a Borg-Warner 35 provided a saving on fuel as well as maintenance about sums up the operational advantages of the unit, although it is generally admitted that the highly skilled driver could do better on both counts.

Of potential interest to the makers and operators of light-delivery vehicles, the Automotive Products Mk III fullyautomatic four-speed torque converter transmission is based on the Mk I and Mk II automatics currently available as an option on BLMC Mini, 1100 and 1300 cars. The Mk III is produced in a form that can be applied to conventional foreand-aft power units as well as transverse engines and is offered with torque ratings of 90 lb ft and 150 lb ft for mating to petrol engines of up to 2+litres.

Reverting to automatics for heavy goods vehicles, it is pertinent to ask whether an established type of gearbox could be modified in detail to iderease its usefulness and acceptability pending the day—if it ever comes—that a low-cost and efficient infinitely-variable transmission is produced. In the author's opinion the answer is yes.

It should be possible to produce a semi-automatic or fully-automatic epicyclic gearbox to give some of the advantages of an infinitely-variable transmission controlled by a black box mentioned early in the article. Two or more overdrives could be incorporated in the gearbox that would enable the vehicle to be driven at, say, 80 per cent throttle opening (as shown on a dial) and at a near-optimum rpm for the load at road speeds in excess of 35/40 mph.

Semior fully-automatic control giving virtually instantaneous changes would enable this to be done without loss of acceleration potential. It would save a lot of fuel as well as wear and tear. And the driver would like it, once he was accustomed to the routine!