ELECTRIC

Page 62

Page 63

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

TRUCKS for

TRANSPORTING,

ELEVATING and

STACKING

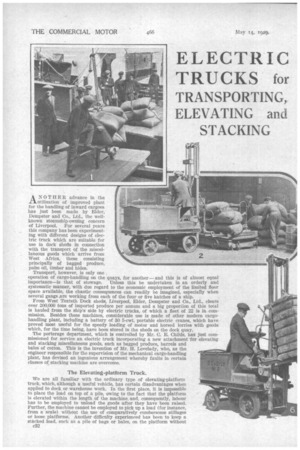

A NOTHER advance in the -Clutilization of improved plant for the handling of inward cargoes has just been made by Elder, Dempster and Co., Ltd., the wellknown steamship-owning concern of Liverpool. For several years this company has been experimenting with different designs of electric truck which are suitable for use in dock sheds in connection with the transport of the miscellaneous goods which arrive from West Africa, these consisting principally of bagged produce, palm oil, timber and hides.

Transport, however, is only one operation of cargo-handling on the quays, for another — and this is of almost equal importance—is that of stowage. Unless this be undertaken in an orderly and systematic manner, with due regard to the economic employment of the limited floor space available, the chaotic consequences can readily be imagined, especially when several gangs ,are working from each of the four or five hatches of a ship.

From West Toxteth Dock sheds, Liverpool, Elder, Dempster and Co., Ltd., clears over 200,000 tons of imported produce per annum and a big proportion of this total is hauled from the ship's side by electric trucks, of which a fleet of 22 is in commission. Besides these machines, considerable use is made of other modern cargohandling plant, including a battery of 30 5-cwt. portable electric cranes, which have proved most useful for the speedy loading of motor and horsed lorries with gooda which, for the time being, have been stored in the sheds on the dock quay.

The porterage department, which is controlled by Mr. C. E. Childs, has just commissioned for service an electric truck incorporating a new attachment for elevating and stacking miscellaneous goods, such as bagged produce, barrels and bales of cotton. This is the invention of Mr. H. Lovelady, who, as the engineer responsible for the supervision of the mechanical cargo-handling plant, has devised an ingenious arrangement whereby faults in certain classes of stacking machine are overcome.

The Elevating-platform Truck.

We are all familiar with the ordinary type of elevating-platform truck, which, although a useful vehicle, has certain disadvantages when applied to clock or warehouse work. In the first place, it is impossible to place the load on top of a pile, owing to the fact that the platform is elevated within the length of the machine, and, consequently, labour has to be employed to unload the goods after they have been raised. Further, the machine cannot be employed to pick up a load (for instance, from a scale) without the use of comparatively cumbersome stillages or loose platforms. Another difficulty experienced has been to keep a stacked load, such as a pile of bags or bales, on the platform without

c32 the tendency for it to be thrown off when the vehicle is travelling around corners or over rough ground. A further drawback lies in the necessary use of very small wheels at thefront, in order to allow the platform to be as near as possible to the floor level, and even then the platform top is usually 12 ins. above the plane of the floor.

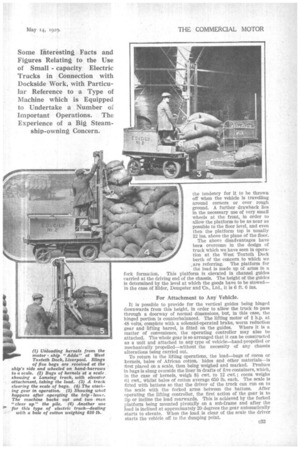

The above disadvantages have been overcome in the design of truck which we have seen in operation at the West Toxteth Dock berth of the concern, to which we are referring: The platform for the load is made up of arms in a fork formation. This platform is elevated in channel guides carried at the driving end of the chassis. The height of the guides is determined by the level at which the goods have to be stowed— in the case of Elder, Dempster and 'Co., Ltd., it is 6 ft. 6 ins.

For Attachment to Any Vehicle.

It is possible to provide for the vertical guides being hinged downwards from this height, in order to allow the truck to pass through a doorway of normal dimensions, but, in this case, the hinged portion is counterbalanced. The lifting motor of b.p. at 48 volts, complete with a solenoid-operated brake, worm reduction gear and lifting barrel, is fitted on the guides. Where it is a matter of convenience: the operating controller may also be attached. The whole gear is so arranged that it can be constructed as a unit and attached to any type of vehicle—hand-propelled or mechanically propelled—without the necessity of any chassis alterations being carried out.

To return to the lifting operations, the load—bags of cocoa or kernels, bales of African cotton, hides and other materials—is first placed on a scale, then being weighed and marked. Produce in bags is slung overside the liner in drafts of five containers, which, in the case of kernels, weigh 8i cwt. to 12 cwt.; cocoa weighs ill cwt., whilst bales of cotton average 650 lb. each. The scale is fitted with battens so that the driver of the truck can run on to the scale with the forked arms between the battens. After operating the lifting controller, the first action of the gear is to tip or incline the load rearwards. This is achieved by the forked platform being mounted pivotally on a sub-frame and after the load is inclined at approximately 20 degrees the gear automatically starts to elevate. When the load is clear of the scale the driver starts the vehicle off to the dumping point.

When we were observing the truck working under normal service conditions, while the motor ship " Adda " was being discharged, the load was set well back on. to the frame in such a position that it was impossible for it to be thrown off by quick turning or by the rough ground. On the way to the pile the driver continued the elevating motion to the desired height and then drove in until the load was about 6 ins, above the lower tiers. By pulling a trip lever on the side of the gear thern whole of the forked platform was caused to tip forward, thus sliding the load off into the position required, without any further handling.

How Time is Saved.

We timed the above operations anti found that it took three seconds to lift and clear the load off the scale, 25 seconds to rim to the pile 50 yards away, and five' seconds to stack the load 5 ft. 6 ins, above ground level. With two machines in operation it is possible to select the packages on landing, weigh and stow them eight or nine high on the quay, a total of 3,000 bags per day—with only the need for two stowers, who are engaged to "lay out" the marks and tidy up the piles.

An important feature of the elevating gear is that it is counterbalanced in such a manner that the return springs for re-setting are quite small, and the energy absorbed in elevating only the platform is just sufficient to overcome the normal frictional losses in the wormgear, pulleys and other working parts.

The elevating unit described can lift a maximum load of 15 cwt. It is patented and is at present being manufactured by Greenwood and Batley, Ltd., Albion Works, Leeds.

At the present time the new patented attachment is fitted to a Lansing truck. Five other conversions are being carried out, four with Lansing trucks and one with a Greenbat.

To show the method of working all inward cargo from a ship, through the channels of quay porterage, and the savings that mechanical Cargo-handling nave effected, we cannot, perhaps, do .better than to explain the two systems in vogue at West Toxteth Dock, Liverpool, i.e.: (a) man-handling, (b) electric trucking.

gang of 25 men working with hand trucks will clear about 2,500 bags of nuts, seeds, etc., per day.. The men engaged would be as follow : Two slingers, two selectors, two scale loaders, one weigher, one clerk, one marker, one unloader, six truckers, eight stowers and a foreman. Four of the stowers would pile bags 5 ft. high and four men would stack them 10 ft. high. The wage bill for the gang for an eight-hour day would be £15 10s.

Costs of Operation.

Let us now examine the cost of operating electric trucks. It is essential to have two men to receive the bags from the ship's derrick, two men to sort the bags, two workers to feed the scale with packages, the weigher clerk and tile marker. From this point the economies begin. Two electric trucks are able to carry out the work of six men with hand-carts, and these can be operated at 18s. per day (including drivers' wages and an operating, maintenance and overhead expenses), assuming 250 working days per year.

Furthermore, only two men need he stationed on the dump to receive the bags and to superintend their orderly arrangement. Thus the gang comprises only 12 men, and their wages would amount to £7 14s. per day.