ANOTHER SMALL-WHEELED LOW-LOADER

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

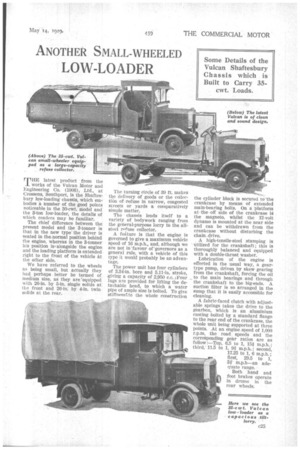

THE latest product from the works of the Vulcan Motor and Engineering Co. (1906), Ltd., at Crossens, Southport, is the Shaftesbury low-loading chassis, which embodies a number of the good points noticeable in the 30-cwt. model and the 3-ton low-loader, the details of which readers may be familiar.

The chief difference between the present model and the 3-tonner is that in the new type the driver is seated in the-normal position behind the engine, whereas in the 3-tonner his position is alongside the engine and the loading platform is extended right to the front of the vehicle lit the other side.

We have referred to the wheels as being small, but actually they had perhaps better be termed of medium size, as they are 'equipped with 26-in. by 5-in, single solids at the front and 26-in. by 4-in, twin solids at the rear. The turning circle of 39 ft. makes the delivery of goods or the collection of •refuse in narrow, congested streets or yards a comparatively simple matter.

The chassis lends itself to a variety of bodywork ranging from the general-purpose lorry to the allsteel refuse collector.

A feature is that the engine is governed to give a maximum vehicle speed of 16 m.p.h., and, although we are not in'favour of 'governors as a general rule, with a vehicle of this type it would probably be an advantage.

The power unit has four cylinders of 3.34-in, bore and 5.11-in, stroke, giving a capacity of 2,950 c.c. 2Four lugs are provided for lifting the detachable head, to which a water pipe of ample size is bolted. To give stiffnesst to the whole construction the cylinder block is secured to'the crankcase by means of extended main-bearing bolts. On a platform at ,the,off side of the crankcase 18 the magneto, whilst the 12-volt dynamo is mounted at the near side and can be withdrawn from the crankcase without disturbing the chain . drive.

A high-tensile-steel stamping is Utilized for the crankshaft; this is thoroughly balanced and equipped with a double-thrust washer.

Lubrication of the engine is effected in the usual way, a geartype pump, driven by skew gearing from the crankshaft, forcing the oil to the main bearings and through the crankshaft to the big-ends. A suction filter is so arranged in the sump that it is easily accessible for cleaning.

A fabric-faced clutch with adjustable springs takes the drive to the gearbox, which is an aluminium casting bolted by a standard flange to the rear end of the crankcase, the whole unit being supported at three points. At an engine speed of 1,000 r.p.m. the road speeds and the corresponding gear ratios are as follow ;—Top, 6.5 to 1, 15i m.p.h.; third,' 11.5 to 1, 91 m.p.h.; second, 17.25 to 1, 6 m.p.h.; first, 29.5 to 1, 3f m.p.h—an adequate range.

Both hand and foot brakes operate in drums in the rear wheels.