Ko m Drivers &Mechanics

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send us an account of any sPeeial incident of your work or experience. If suitable, we will edit your notes, supPly a sketch when required, and pay you for everything published. Mention your employer's name, in confidence, as evidence of good faith. Address to The Editor, THE COMMRRC1AL MOTOR, Rosebery Avenue, London, E.C.

Light Up Your Lamps At— SAO on Thursday ; 3.42 on Friday ; 8.43 on Saturday; 8.46 on Monday ; 8.47 on Tuesday ; 8.48 on Wednesday.

A Novel Use for Old Sparking Plugs.

[1495] " P.McI," (Tighnabruaich) writes :—" I have lately carried out a small repair to the low-tension plug and hammer of an old-type engine, and I think a short description of the method, and more particularly of the material employed for the repair, might be useful to some of your 'D, and M.' readers. "The contact points were completely burnt away, and, as starting was made extremely difficult thereby, I decided to renew them. The easiest way to effect a repair is to put in a new plug and hammer, but this makes rather too expensive a job, and if the points can be cheaply renewed, it is advisable to do so. If two points are put in the plug, as shown in the sketch [We have had this redrawn.—En.] when one is burnt the plug can be easily turned round to bring the other in position by slightly slackening the insulation.

"The material used was the central electrode of an old sparking-plug, and in connection with the latter I should strongly recommend drivers not to throw away any of their old plugs, as these very often come in useful for various repairs. For instance, the electrodes make excellent points for the low-tension plugs and hammers, and are also quite suitable for use as contact-breaker points on a high-tension magneto, and, although when used for this purpose, they may not last quite so well as platinum, they can be very easily„renewed and are much cheaper.

"The hole in the low-tension plug should be drilled to the same diameter as the electrode to be used. In this case, the size of the hole was in. The electrode was very slightly larger than this, and, after being filed, was driven tightly into position. "1 may mention that after refitting the contact points of a magneto with pieces of plug electrode, the magneto has been used on an engine for several months without aey trouble being experienced."

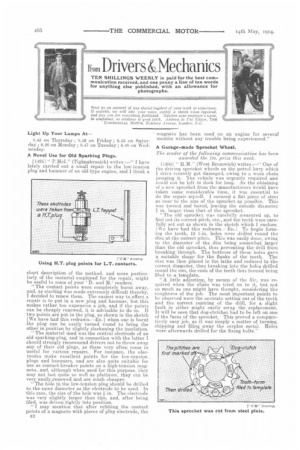

A Garage-made Sprocket Wheel.

The sender of the following communication has been awarded the Ws. prize this -week.

[1496] " H.M." (West Bromwich) writes :—" One of the driving sprocket wheels on the petrol lorry which I drive recently got damaged, owing to a worn chain jumping it. The vehicle was urgently required and could not be left in dock for long. As the obtaining of a new sprocket from the manufacturers would have taken sonic considerable time, it was essential to do the repair myself. I secured a flat piece of steel as near to the size of the sprocket as possible. This was turned and bored, leaving the outside diameter in. larger than that of the sprocket.

"The old sprocket was carefully measured up, to find out its correct pitch, etc., and the teeth were carefully set out as shown in the sketch which I enclose. We have had this redrawn.-En.] To begin forming the teeth, 12 I-in, holes were drilled round the disc at the correct pitch. This was easily don; owing to the diameter of the disc being somewhat larger than the old sprocket, thus preventing the drill from breaking through. The bottoms of these holes gave a suitable shape for the flanks of the teeth. The disc was then placed in the lathe and reduced to the correct diameter, thus breaking into the holes drilled round the rim, the ends of the teeth thus formed being filed to a. template.

"A little adjusting, by means of the file, was required when the chain was tried on to it, but not so much as one might have thought, considering the roughness of the job. The most important points to be observed were the accurate setting out of the teeth and the correct centring of the drill, for a slight fault in either might easily scrap the replacement. It will be seen that dog-clutches had to be left on one of the faces of the sprocket. This proved a comparatively easy job, as it was simply a matter of turning, chipping and filing away the surplus metal. Holes were afterwards drilled for the fixing bolts." Clearance Fits as Gauged by the Callipers.

[4971 " X." (Cardiff) writes :—" I offer the following tip for the benefit of the younger readers of the D. and M.' pages. I have come across many young litters and turners who cannot make a proper callipermeasurement-seasy though it seems -with the cers taint/ of attaining the correct running or working fits. "Of course, everybody who is in the trade knows that callipers must touch the work as lightly as possible, and I have compiled a table from the amount of side play of the callipers which I have observed when making running or working fits, such as those required for a journal in a solid box.

When using the table, for the bore of a bearing, the inside-callipers are set to the correct diameter of the shaft, which is obtained by means of a micrometer or the outside-callipers. One foot of the callipers is then put into the bearing, which is bored out until the other foot gives the correct side play according to the table. For instance, if you want to fit a 2 in. shaft into a bearing, the calipers are set to 2 ins. exactly, by the means before mentioned, and the joursal bored out to such a clearance as will permit the play at the top foot of the calipers to be in., that is to say, it can be moved from side to side over a distance equal to that amount.

"If the job is required to have a push fit. one-third should be taken off the table of plays ' : this will give the required fit.

Da Your Gears Jam When Changing Speed?

[1498] " G.W.E." (Thornton Heath) writes:— " Many of my fellow drivers have no doubt noticed that, when sliding-gears have worn loose on their shafts, there is a decided tendency for the gears to tilt, and jamming is thus caused when they are moved from one position to another. As a rule, repairers have little trouble from this defect, as by the time the gears get to them they usually require renewal, but sometimes it happens that the teeth of the gears last so well that the holes in the bosses have time to wear quite a lot.

" I enclose a sketch [We have had, this redrawn.— En. and description of a method which I used for taking up the wear in the squared hole of a sliding gear in the gearbox of the ear I drive. Two makingup plates were cut from -i/s in. mild steel and squared out to slide freely on the shaft, which happened to be one of the square type. These were afterwards drilled out for setscrews and carefully secured to the gear-wheel bosses, which were softened for that pur pose. After being set true and tried in position, they were removed, case-hardened, and finally fitted. " Care was taken to ensure that the thickness of the plates did not interfere with the correct lateral meshing of the gears, and it was found that after assembling the gearbox, the operation of changing speed was rendered much more certain than before, .while the forks and levers were not subjected to the .same strain as when the tilting of the gear had to be overcome by force."

A Lapping Tool with an Automatic Grinding-compound Feed, 114991 " F.C.F." (Chalvey) writes :—" During the course of my work I have to overhaul a large number of petrol engines, and the time allowed for such overhauls being very limited, everything has to be done as rapidly as possible. Now, one of the chief troubles that I have experienced is that the crankshaft pins wcar.more or less oval, and not having the conveniences to hand, it is impossible for me to have them ground without sending thorn away. As there is not sufficient time for this, I have to do what I can. I used to do the job with a file, afterwards smoothing the pin down with emery cloth. "Finding this operation very tedious, and not altogether satisfactory. I made a crankshaft rap which has given excellent results.. I enclose a sketch [We have had this redrawn.—Eiej of the device, which consists of two halves held together by a hinged joint, one of the halves being fitted with a swing bolt, which drops into a slot in the other. The two halves were forged from in. mild steel, this thickness being required to overcome any tendency to springing when encountering inequalities on the crank-pin.

" Each of the halves is fitted with a handle made

from in. gas-pipe, suitable lengths being screwed into them. Each handle is provided with a screwplug at the outer end, and this plug is only fitted finger-tight, so that it can be easily removed for insetting the mixture of emery powder and oil.

"The actual lapping surface consists of a pair of split brasses, lined with white-metal, as I found that the white-metal seems to retain the emery powder longer on its surface owing to its being more soft than the shaft. A clearance of at least 1tts in. is allowed between the two halves of the bearing, and slightly more between the two halves of the lapping-tool. This is to allow for the wear which must take place on the white-metal.

"If it be found necessary, channels can be out right across the brasses, and holes must be drilled in them in line with the holes in the handles, so that the grinding mixture contained in them will be allowed to flow between the crank-pin and the tool.

"In making the tool, after fitting the two halves together, they should be bored out to the outside diameter of the brasses, so that they will press equally all over them.

"To use the device, the csank-pin is first filed as carefully as possible, and afterwards lapped. Plenty of oil should be used when lapping, as this prevents the scoring of the shaft."