From the I raking Boar by Graham MontgomeriE With increasing

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

pressure on manufacturers to cut noise levels and with oil companies beginning to degrade fuel, the time could be right for Perkins to give the industry some lip — "squish lip" to be precise

WAS WAY back in 1974 that erkins Engines Ltd published etails of a new combustion vstem which centred round a nange in piston bowl shape.

Known at the "squish lip", it ttracted a great deal of attenon by virtue of the claims made y Perkins that the engine could leet the 1977 California Air Reources Board (CARB) legisition for exhaust emissions.

This applied to the oxides of itrogen in particular, with gures quoted at the time as .1gm/bhp.h for a squish lip and 3.1gm/bhp.h for a standard roduction engine.

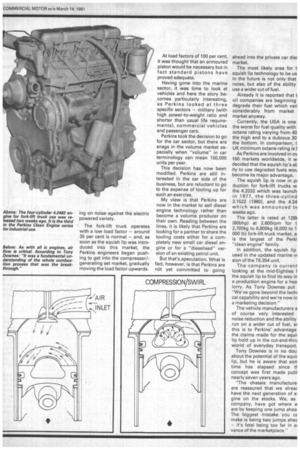

Since then, apart from appearnces in industrial guise, the quish lip concept seemed to the utsider to have disappeared — ut not as far as Perkins were oncerned, as I discovered when spoke to director (engineering) )r the company Tony Downes. A glance at the accompanying iagrams will show that the ombustion bowl shape in the iston varies considerably from le norm usually typified by the pheroidal combustion chamer. This re-entrant type of bowl meant that the rate of maximum cylinder pressure generation could be lowered which, in turn, meant a softer diesel "knock".

It also implied that lighter scantlings and reciprocating parts could be used or, alternatively, that the existing build could be retained and used at higher peak pressures.

The total engine tolerance build (for example, piston height, nozzle height and so on) is no different from what has been used in the past. The production costs are approximately the same for a squish lip versus a "conventional" engine as the major change is the piston bowl shape and that doesn't make much difference in overall engine cost terms.

The compression ratio varies between 18 and 19 to 1 depending upon the engine, but the engine has been run as low as 16 to 1 and as high as 22 to 1.

The problem with running at very high compression ratios is that gasket thickness tolerance can have a disproportionate effect.

The current CR is typical of e standard toroidal chamber en gine.

According to Tony Downes the whole combustion systerr can he tuned by playing arounc with a number of variables — chamber volume, chambei maximum diameter, flank anglE and bowl depth. "It was a fund& mental understanding of thE whole combustion process tha was the breakthrough."

The squish lip engine was de signed originally to meet thE North American legislation or emissions, which it did comfort ably. However, the US Class V diesel market did not take off a: expected with many operator: preferring to stay with their trieE and trusted petrol engines. Accordingly, Perkins went int( the fork-lift truck market compet Below: As with all ic engines, air flow is critical. According to Tony Downes: "It was a fundamental understanding of the whole combustion process that was the breakthrough." ing on noise against the electric powered variety.

The fork-lift truck operates with a low load factor — around 35 per cent is normal — and, as soon as the squish lip was introduced into this market, the Perkins engineers began pushing to get into the compressor!generating set market, gradually moving the load factor upwards. At load factors of 100 per cent, it was thought that an armoured piston would be necessary but in fact standard pistons have proved adequate.

Having gone into the marine sector, it was time to look at vehicles and here the story becomes particularly interesting, as Perkins looked at three specific sectors — military (with high power-to-weight ratio and shorter than usual life requirements), commercial vehicles and passenger cars.

Perkins took the decision to go for the car sector, but there are snags in the volume market especially when "volume" in car terminology can mean 150,000 units per year.

This decision has now been modified. Perkins are still interested in the car side of the business, but are reluctant to go to the expense of tooling up for such an exercise.

My view is that Perkins are now in the market to sell diesel engine technology rather than become a volume producer on their own. Reading between the lines, it is likely that Perkins are looking for a partner to share the tooling costs either for a completely new small car diesel engine or for a "dieselised" version of an existing petrol unit.

But that's speculation. What is fact, however, is that Perkins are not yet committed to going ahead into the private car dieE market.

The most likely area for t squish lip technology to be us in the future is not only that noise, but also of the ability use a wider cut of fuel.

Already it is reported that t oil companies are beginning degrade their fuel which vani considerably from market market anyway.

Currently, the USA is one the worst for fuel quality with octane rating varying from 40 the high end to a dubious 30 the bottom. In comparison, t UK minimum octane rating is E As Perkins are involved in ov 160 markets worldwide, it w decided that the squish lip's at ity to use degraded fuels wou become its major advantage.

The squish lip is now in pi duction for fork-lift trucks w the 4.2032 which was launch in 1977, the three-cylind 3.1522 (1980), and the 4.24 which was announced tv weeks ago.

The latter is rated at 128k (80bhp) at 2,600rpm for t 2,700kg to 6,800kg (6,000 to 1 000 lb) fork-lift truck market, a is the largest of the Perki "clean engine" family.

In addition, the squish lip used in the updated marine v( sion of the T6.354 unit.

The company is current looking at the mid-Eighties f the squish lip to find its way in a production engine for a hea lorry. As Tony Downes put "We've gone beyond the techi cal capability and we're now in a marketing decision."

The vehicle manufacturers a of course very interested noise reduction and the ability run on a wider cut of fuel, ar this is to Perkins' advantage the claims made for the squii lip hold up in the cut-and-thru world of everyday transport.

Tony Downes is in no dou about the potential of the squiE lip, but he is aware that son time has elapsed since tt concept was first made publ nearly seven years ago.

"The chassis manufacture are reassured that we alreac have the next generation of e gine on the stocks. We, as company, have got where v% are by keeping one jump ahea. The biggest mistake you CE make is being two jumps aheE it's fatal being too far in ai vance of the marketplace."