Milnes-Daimler, Ltd.

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

Principal Exhibits :—One 28h.p. Bus Chassis ; two Buses ; one Char-a-hancs ; one Lorry ; one Lorry Chassis.

Of the vehicles and chassis exhibited by Milnes-llaitnler, Limited, perhaps the most interesting is a beautifullyfinished 28h.p. chassis which, on clos-, inspection, reveals many important and interesting improvements on previous designs, in addition to its being a splendid example of high-class workmanship. This chassis has a pressed steel frame, and is mounted on semi-elliptic springs, the rear ones being very long and flexible. The engine cylinders are cast in pairs, and have a bore of about 4 s-t6ths inches in diameter, with a piston-stroke of si• inches, and normal power is developed at 850 revolutions per minute. The crank case has vertical ribs, which are provided for the purpose of keeping the oil cool. The lubrication is ensured by the oil's being forced to the bearings by means of a plunger pump, which is mounted on the crank case and is driven from an eccentric pin,, turned integral with the camshaft, by a suitably-jointed connecting rod, as illustrated. The introduction of this system of lubrication re

lieves the dash-board of its former bewildering array of sight-feed lubricators, and, in practice, has done much to abate the smoke trouble. The cylinders are cast in pairs, and, to ensure proper distribution of the lubrication, the pistons have each three oil-distributing grooves cut in them. All valves are mechanically operated, and the control lever is now fitted on the steering wheel. This lever rnay be set for slow running, and, for quick acceleration, a foot-pedal is provided which, from

practical experience with this bus, we can say is a very useful and handy means of control, especially for congested London traffic. The bus picks up remarkably on the application of the pedal, and the flexibility of the engine is undoubted. The radiator attachment has been mounted in a novel and scientific manner, and no trouble should be experienced with contraction and expansion troubles as is so often the case with large honeycomb radiators. The radiator is pivoted, as shown in the sketch which we reproduce, and the )p is stayed to the dash-board by the top portion of the bonnet, which is bolted to it and to the bonnet-rest, which is fixed to the dash-board. This has an additional advantage, as the driver is no longer in a position to throw the bonnet about in the brutal manner one so often sees. Accessibility of the engine does not suffer in any way due to this change.

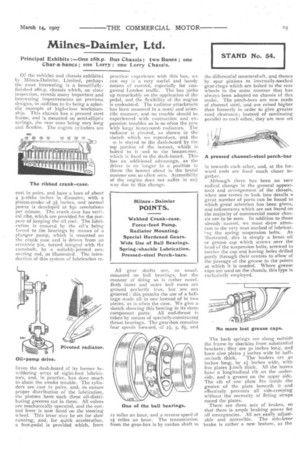

All gear shafts are, as usual, mounted on ball bearings, but the manner of doing so is rather novel. Both inner and outer ball races are ground perfectly true, but are not grooved : this permits the use of a ballcage made all in one instead of in two pieces, as is often the case. We give a sketch showing this bearing in its three component parts. All end-thrust is taken by means of specially-constructed thrust bearings. The gear-box contains four speeds forward, of 2.&', 5, 8, and

_

12 miles an hour, and a reverse speed of 2i miles an hour. The transmission from the gear-box is by cardan shaft to

the differential countershaft, and thence by spur pinions to internally-toothed gear-rings which are bolted to the rear wheels in the same manner that has always been adopted on chassis of this make. The perch-bars are now made of channel steel, and are raised higher than formerly in order to give greater road -clearance; instead of continuing parallel to each other, they are now set in towards each other, and, at the forward ends are fixed much closer together.

Although there has been no very radical change in the general appearance and arrangement of the chassis, when one comes to look into details a great number of parts can be found to which great attention has been given, and refinements which are not found on the majority of commercial motor chassis are to be seen. In addition to those already named, we must draw attention to the very neat method of lubricatingthe spring suspension bolts. As illustrated, this is simply a brass oil or grease cap which screws over the head of die suspension bolts, screwed to receive the cap and having holes drilled partly through their centres to allow of the passage of the grease to the points at which it is needed. Where grease caps are used on the chassis, this type is exclusively employed.

The back springs are slung outside the frame by shackles from substantial brackets; they are so inches long, and have nine plates 3 inches wide by half an-inch thick. The leaders are 40 inches long, by 21. inches wide, with five plates *-inch thick. All the leaves have a longitudinal rib on the under-. side, and a groove on the upper side. The rib of one plate fits inside the groove of the plate beneath it and effectively prevents all side-creeping without the necessity of fitting straps round the plates. There are three sets of brakes, so that there is ample braking power for all emergencies. All are easily adjustable and accessible. The side-lever brake is rather a new feature, as the V-brake drums are really part of the 'rims of the back wheels.

A 28h.p. omnibus, built to the order of the Great Western Railway Company, is also shown on this stand. The specialaroint of this body is that it has cross seats and luggage accommodation. A 3o-seated char-a-bancs, also for the Great Western Railway Company, forms another interesting exhibit -on the stand. This body is very smart, and is a fine example of coachwork ; it is provided with a canopy, and is built on a 28h.p. chassis, which is similar in construction to the one above described. A private omnibus, in natural wood, for Thomas Tilling, Limited, is another fine piece of coachwork, and has a very imposing appearance. The body-building fittings, and finish reflect the greatest credit upon Christopher Dodson, Limited.

The chassis of all these vehicles have the following dimensions : Total length, to feet it inches; width over oil-caps, 6 feet 61 inches; wheel-gauge, 5 feet 6 inches ; wheel-base, 13 feet , and height from ground to top of frame, 2 feet to inches when unladen.

A 3-ton lorry and standard chassis are also shown, together with a fine assortment of component parts, including crankshaft, connecting rods, and pistons, differential shaft with all its mountings, gear-box shafts, wheels, sleeves, etc. An examination of these parts shows the perfect proportions of all wearing or driving parts, and the high-class workmanship which is put into them. These parts, of course, appear to have a much higher finish than one would expect to find on a standard chassis, but this appearance is greatly due to their having been subjected to sand-blast treatment. Mr. H. G. Burford, the managing director, is justly proud of his company's exhibits, to the perfection of which his own abilities as a mechanical engineer, and a good man of business, have so largely Contributed.

In our issue of October t8th, 1906, we gave a fuller general description of the 28h.p. chassis, and we would refer our readers to that issue for all details not mentioned here. A large number of these chassis have recently been delivered for omnibus service in London and the pnovinces. There can be no question as to the silence and smooth running of these vehicles; and, of their ease of manipulation in close traffic, we are convinced from personal experience; whilst the visit we paid to the company's factory in December last, coupled with inspection after long use, has satisfied us of the unusual life of the toothed gear wheels and other vital parts of these machines.