31.—Removing Commer Car Crankshaft.

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

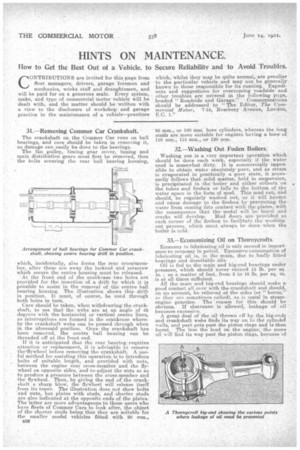

The crankshaft on the Commer Car runs on ball hearings, and care should be taken in removing it, as damage can easily be done to the bearings. The fan pulley, timing gear cover, timing and main distribution gears must first he removed, then the bolts securing the rear ball bearing housing, which, incidentally, also forms the rear cross-member, after these are aiva,y the locknut and setscrew which secure the centre housing must be released.

At the ft-ant end of the crankcase two holes are provided for the insertion of a drift by which it is possible to assist in the removal of the centreball bearing housing. The. illustration shows this drift in position. It. must, of course, be used through both holes in turn.

Care should be taken, when withdrawing the crankshaft, to see that the webs are at an angle of 45 degtees with the horizontal or vertical centre lines, as interruptions are formed in the crankcase whereby the crankshaft webs can be passed through when in the aforesaid position. Once-the crankshaft has been removed, the centre ball bearing can be threaded off at the front end. •

If it is anticipated that the rear bearing requires attention or replacement, it-is advisable to remove the4flyWheel before removing the crankshaft. A.useful method for assisting this operation is to introduce bolts of suitable length, and provided with nuts, between the engine rear cross-member and the flywheel on opposite sides, and to adjust the nuts so as to produce a pressure between the cross-member and the flywheel. Then, by giving the end of the crankshaft a sharp blow, the flywheel will release itself from its taper. The illustration does not show bolts and nuts, but plates with studs, and shorter studs are also indicated at the opposite ends of the plates. The latter are more advantageous to those users who have fleets of CommerCars to look after, the object of the shorter studs being that they are suitable for the smaller model vehicles fitted with 90 mm.,

B3f;

95 mm.„ Or 100 ram. bore cylinders, whereas the long studs are more suitable for engines having a bore of 110 itnia, 115 ram., .or 120 ram.

32.—Washing Out Foden Boilers;

Washing. out is a. very important operation which should be done each week, especially if the water used is somewhat dirty. It is commercially impossible to obtain water absolutely-pure, and as steam is evaporated in praCtically a pure state, it .necessarily follows that solid matter, held in suspension, is precipitated in the boiler and either collects on the tubes and firebox or falls to the bottom of the water space in the form of mud. This mud can, and should, be regularly washed but, or it will harden and cause damage to the firebox by preventing the water from coming into contact with the plates, with the consequence that the metal will 'be burnt and

cracks will. develop. Mud doors are provided at. each corner of the firebox to facilitate the washingoat process, whiCh must always be done when the boiler is cold.

33.—Economizing Oil on Thornycrofts.

Economy in lubricating oil is only second in importance to economy in petrol. Excessive consumption of lubricating oil is, in the main, due to badly fitted bearings and unsuitable oils.

Oil is fed to the main and big-end bearings under pressure, which should never exceed 15 lb. per sq. in. : as a matter of fact, from 5 to 10 lb. per sq. in. is at all times sufficient. All the main and big-end bearings should make a good contact allover with the crankshaft and should, on no aecorint, be relieved at the sides (or." hems,' as they are sometimes called), as is wataI in steamengine practice. The reason fer this should 'be obvious. If clearanceis allowed, leakage of oil becomes excessive.

A great deal of the oil thrown off by the big-ends and crankshaft webs finds its way en to the cylindec walls, and part gets past the piston rings and is then burnt. The less the load an the engine, the more oil will find its way past the piston rings, because of the increased vacuum during the suction stroke. This is one good reason why a commercial vehicle is a hetter-paying proposition when running fully loaded.

In order to take up the big-ends it is necessary slightly to reduce the thickness of the brass shims, imt this operation must be done. carefully, and they should be reduced equally all over and with absolutely flat surfaces, otherwise there will be parts not in contact with the metal next to them, ana through the spaces thus formed oil will ascape. The inner edges of these shims should actually bear against the crankpins, as shown in the diagram, otherwise there is nothing to prevent oil pouring through the open

ings left, making four points of exit on each big-end.

Under no conditions should the connecting rods dip into the oil in the crankcase and, if it is suspected that the indicator is sticking or reading incorrectly, the ti-ycock on the sump should be used.

Any Gingrich becomes not much thicker than water when/ heatedto the normal _engine temperature. should be avoided. On the other hand, very, thick oils will make the engine exceedingly stiff and hardto start when cold, and'an aPpreciable drop in power at high speeds would be noted, owing to the fact that the oil film on the cylinder walls is thicker and requires more power to displace.