Converter-only transmission

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

Variable kinetic drive gives high torque multiplication and efficiency without auxiliary gearing

by Paul Brockington • A four-element torque converter transmission has been developed by Variable Kinetic Drives Ltd, Pillory Green, Napton-on-the-Hill, near Rugby, that provides stepless drive characteristics that are suitable for commercial vehicles in the light to medium category as well as cars without auxiliary ratio-change mechanical gearing, apart from a reverse gear. A version for heavier commercial vehicles would be equipped with a mechanical auxiliary gear giving a low-ratio drive in addition to direct drive to provide a crawler gear and to increase overrun braking.

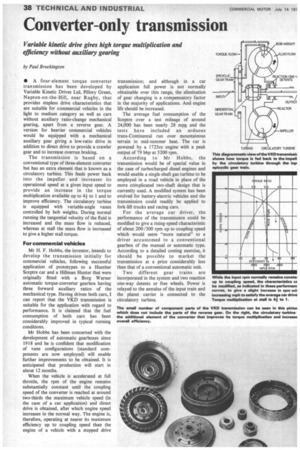

The transmission is based on a conventional type of three-element converter but has an extra element that is known as a circulatory turbine. This feeds power back into the impeller and increases its operational speed at a given input speed to provide an increase in the torque multiplication available up to to 1 and to improve efficiency. The circulatory turbine is equipped with " variable-angle vanes controlled by bob weights. During normal running the tangential velocity of the fluid is increased and the mass flow is reduced, whereas at stall the mass flow is increased to give a higher stall torque.

For commercial vehicles Mr H. R Hobbs, the inventor, intends to develop the transmission initially for commercial vehicles, following successful application of prototypes to a Humber Sceptre car and a Hillman Hunter that were originally fitted with a Borg Warner automatic torque-converter gearbox having three forward auxiliary ratios of the mechanical type. Having driven both cars, I can report that the VKD transmission is suitable for the application with regard to performance. It is claimed that the fuel consumption of both cars has been considerably improved in typical running conditions.

Mr Hobbs has been concerned with the development of automatic gearboxes since 1918 and he is confident that modification of vane configurations (standard components are now employed) will enable further improvements to be obtained. It is anticipated that production will start in about 12 months.

• When the vehicle is accelerated at full throttle, the rpm of the engine remains substantially constant until the coupling speed of the converter is reached at around two-thirds the maximum vehicle speed (in the case of a car application) and direct drive is obtained, after which engine speed increases in the normal way. The engine is, therefore, operating at nearer its maximum efficiency up to coupling speed than the engine of a vehicle with a stepped drive transmission; and although in a car application full power is not normally obtainable over this range, the elimination of gear changing is a compensatory factor in the majority of applications. And engine life should be increased.

The average fuel consumption of the Sceptre over a test mileage of around 24,000 has been nearly 28 mpg and the tests have included an arduous trans-Continental run over mountainous terrain in mid-summer heat. The car is powered by a 1725cc engine with a peak output of 79 bhp at 5200 rpm.

According to Mr Hobbs, the transmission would be of special value in the case of turbocharged diesel engines and would enable a single-shaft gas turbine to be employed in a road vehicle in place of the more complicated two-shaft design that is currently used. A modified system has been evolved for battery-electric vehicles and the transmission could readily be applied to fork-lift trucks and racing cars.

For the average car driver, the performance of the transmission could be modified to give a rising-speed characteristic of about 200/300 rpm up to coupling speed which would seem "more natural" to a driver accustomed to a conventional gearbox of the manual or automatic type. According to a detailed costing exercise, it should be possible to market the transmission at a price considerably less than that of a conventional automatic unit.

Two different gear trains are incorporated in the system and two reaction one-way detents or free wheels. Power is relayed to the annulus of the input train and the planet . carrier is connected to the circulatory turbine.