4-litre Engine Hauls 24 Ton ip 1-in-3 Hill

Page 58

Page 59

Page 60

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

By

John F. Moon,

A.M.I.R.T.L.

ALTHOUGH heavy vehicles on test frequently attempt the ascent of Mow Cop, a fearsome climb culminating in a stretch of 1-in-31 gradient, the appearance of vehicles on such tests is still novel enough to attract the interest of local residents.

Rarely do vehicles of more than 20 tons gross attempt the upper slopes of this hill, so it was with certain misgivings that I drove the latest Foden eight-wheeler, running at over 24-1 tons gross weight, towards this steep section,particularly as the test was made under icy conditions and the test vehicle had a single-drive bogie only.

However, pausing for breath before the final ascent and engaging the lowest of the 12 gears available, the Foden was headed up the hill and scaled the 1-in-31 section at 2,000 engine r.p.rn., the speedometer registering about 11 m.p.h., a magnificent performance from a 4-litre engine.

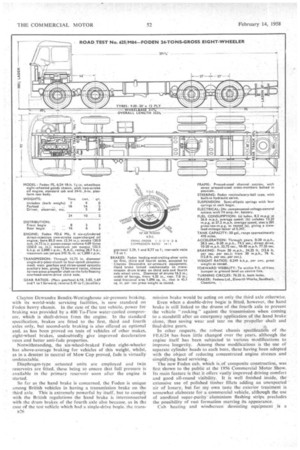

Sensational Climax This was the sensational climax of a full road test of this latest Foden maximum-load eight-wheeler. Since a Foden eight-wheeler was last tested by The Commercial Motor nearly eight years ago. the basic chassis specification has been changed very little, but the vehicle has been altered in appearance by the adoption, 18 months ago, of a new cab, whilst within the past few months air braking has been adopted to bring the chassis specification more into line with general export-market demands for standardization.

Another feature of the vehicle tested was that it had the new Foden self-contained power-steering gear which although it has been thoroughly developed over the past year or more, has only just been offered as optional equipment.

Although by virtue of the recirculatory-ball-type steering fitted as standard to all Foden vehicles the steering of the standard eight-wheeler is light by current eight-wheeler standards, the new power-steering gear removes almost all the hard work from driving this vehicle.

It makes shunting and the negotiation of sharp corners a lighter and faster operation and, as the Foden engineers themselves have proved, makes the vehicle infinitely safer to handle in the event of a front tyre becoming punctured, a front brake grabbing on wet roads, or sharp bumps being encountered.

An important feature of the new Foden power-steering system is that the same assembly can be used on all Foden vehicles, including heavy dumpers running at more than 45 tons gross weight. Another point is that, being selfcontained, the normal steeritig linkages can still be employed, the power acting directly on the steering-box drop-arm. The gear has been laid out so that the same basic steering-column components can be employed whether power steering is specified or not.

The vehicle offered for test, an FE.6/24 model, had the Foden FD.6 Mk. II six-cylindered two-stroke supercharged oil engine which, as installed in the chassis, develops 122.5 b.h.p. (net) at 2,000 r.p.m., the net torque output being 342 lb.-ft. at 1,500 r.p.m.

The standard gearbox for the chassis is a four-speed constant-mesh unit, but it is offered with a variety of auxiliary gearboxes which are unit-mounted with the main box and the engine, the complete assembly being rubbermounted at three points.

The test chassis had the three-speed version of this auxiliary gearbox, giving 12 forward and three reverse speeds, but it is also possible to specify the main gearbox with oneor two-speed auxiliary units, giving either direct and overdrive ratios or direct and underdrive ratios.

The choice of which ratios to specify depends entirely on the type of operation contemplated, but for normal working in Great Britain over main-road trunk routes, whilst the main gearbox alone would be satisfactory, it would be advisable to specify either the three-speed auxiliary unit, as tested, or the two-speed direct-and-overdrive assembly, as the overdrive section gives definite fuel economy and speed • advantages.

Clayton D'ewandre Bendix-Westinghouse air-pressure braking, with its world-wide servicing facilities, is now standard on Foden heavy chassis. In the case of the test vehicle, power for braking was provided by a 400 Tu-Flow water-cooled compressor, which is shaft-driven from the engine. lo the standard specification, brakes are fitted to the "first, third and fourth axles only, but second-axle braking is also offered as optional and, as has been proved on tests of vehicles of other makes, eight-wheel brakes, undoubtedly give improved deceleration rates and better anti-fade properties.

Notwithstanding, the six-wheel-braked Foden eight-wheeler has above-average braking for vehicles of this weight, whilst, as in a descent in neutral of Mow Cop proved, fade is virtually undetectable.

Diaphragm-type actuated units are employed and twin reservoirs are fitted. these being to ensure that full pressure is available in the primary reservoir soon after the engine is started.

So far as the hand brake is concerned, the Foden is unique among British vehicles in having a transmission brake on the third axle. This is extremely powerful try itself, but to comply with the British regulations the hand brake is interconnected with the drum brakes of the fourth axle also because, as in the case of the test vehicle which had a single-drive bogie. the trans p26 mission brake would be acting on only the third axle otherwise.

Even when a double-drive bogie is fitted, however, the hand brake is still linked to the drums of the fourth axle to prevent the vehicle " rocking" against the transmission when coming to a standstill after an emergency application of the hand brake alone, thus saving wear and tear on the propeller shaft and final-drive gears.

In other respects, the robust chassis specification of the FE.6/24 has -been little changed over the years, although the engine itself has been subjected to various modifications to improve longevity. Among these modifications is the use of separate cylinder heads to each bore, these having been adopted with the object of reducing concentrated engine stresses and simplifying head servicing. The new Foden cab, which is,of composite construction, was first shown to the public at the 1956 Commercial Motor Show. Its main feature is that it offers vastly improved driving comfort and good all-round visibility. It is well finished inside, the extensive use of polished timber fillets adding an unexpected air of luxury, but for my own taste the exterior treatment is somewhat elaborate for a commercial vehicle, although the use of anodized super-purity' aluminium flashing strips precludes the possibility of rust formation marring its appearance.

Cab heating and windscreen demisting equipment is a standard feature. This has been provided not only to enhance the driver's comfort, but also to ensure that drivers do not over-blank the radiator in cold weather with the object of warming up the cab, this having been shown in the past to be likely to cause boiling, with subsequent damage to the cylinder heads.

The licensing weight of the test vehicle, complete with a heavy 24-ft. 6-in, platform test-weight body, was 6 tons 17 cwt. and ready for the road the kerb weight was recorded as 7 tons 9 cwt. Iron weights totalling 16 tons 16+ cwt. were added and, complete with myself and two Foden representatives in the cab, the eight-wheeler weighed 24 tons 101 cwt.. the payload being + ton in excess of that legally allowed. A distribution check showed the 16 tyres of the vehicle to be about equally loaded.

Using a test tank for maximum accuracy, the Foden was taken over a 34.2-mile-long undulating fuel-consumption course which, starting from Sandbach, passed through Middlewich, Northwich, Mere, Knutsford. Holmes Chapel and back to Sandbach.

Conditions were bad. the roads being icy in parts and the ambient temperature 34° F. only. This meant that the engine. the radiator of which was unblanked. was running at only 135° F.

High Time-load-mileage Factor

Seven stops were made because of traffic conditions, despite which the course was completed at an average speed of 26.6 m.p.h., and the use of 4.17 gallons of fuel showed the average consumption rate to be 8.2 m.p.g. This resulted in a time-load-mileage factor of 5.347, which is excellent for this class of vehicle in view of the adverse conditions.

On the second day of the test this same run was made with the test weights removed, the running weight being 8 tons 2 cwt. because of the timber baulks which were left on the platform. Bad traffic conditions were encountered during the test and 10 stops were made, with the result that the average speed was very little higher than that recorded during the laden run, -being 27.2 m.p.h. The fuel-consumption rate was 13.25 m.p.g.; a not unreasonable figure and one owing much to the economy aspect of the overdrive 12th gear.

Because the maximum torque of the Foden two-stroke engine is developed at the relatively high speed of 1,500 r.p.m., good acceleration is dependent upon keeping the engine speed high and making full use of the gearbox ratios available. Even so, acceleration rates as good as those recorded with vehicles fitted with engines which develop their maximum torque lower down the speed range cannot reasonably be expected.

Nevertheless, it was possible to obtain quite good "through the gears" figures between 0 and 30 m.p.h. Engine torque characteristics are reflected by the relatively long time taken to get from 10 to 30 m.p.h. in direct drive, Le., fourth gear main box, middle gear auxiliary box.

Gearbox Must be Used Drivers of vehicles with this engine quickly become accustomed to the increased use of the gearbox necessary to obtain good road performance, however, and, properly driven. a Foden eight-wheeler is perfectly capable of holding its own against 24-tanners of other makes.

The use of the auxiliary gearbox is not as complicated as it sounds, as, 'being an epicyclic unit, it can be pre-selected and engaged by quick depression of the clutch in the same way as the change on a two-speed axle is effected.

A suitable level stretch of ice-free road was found for the brake tests and the stopping distances recorded were satisfactory for this type of brake. There was a slight detectable delay in the system, however, which had the effect of increasing the stopping distances, and skidding of the rear-bogie wheels had a detrimental effect also.

Although the lag between the operation of the brake pedal and build-up of full retardation effect is in the region of 0.6 second only. if this could be reduced better figures would be obtained. Similarly, of course, had brakes been fitted to all four axles the front wheels would have been able to play their part to a greater extent and partially compensate for the locking of the rear wheels.

Various stops made from 20 m.p.h. with the hand brake alone showed it to he extremely efficient and readings of up to 40 per cent. were obtained without undue effort having to be applied to the lever.

The climb up Mow Cop was made in an ambient temperature of 34° F. The hill is 0.85 mile long and has an average gradient of approximately 1 in 9 with several bad corners to negotiate.

Although I had never driven any vehicle up this gradient before, I managed to get the Foden to the summit in 15+ minutes, most of the climb being spent in second low. The temperature of the coolant in the radiator header tank rose from 158° F. to 165° F, whilst that of the coolant in the engine cylinder heads rose by 6° F. to 156° F. With the engine on the governor, the speed up the greater part of the hill was just over 3 m.p.h. and at no time was any smoking noticed at the exhaust outlet.

Returning to the steepest section of the hill, which occurs at "The Cheshire View Inn" and where the gradient meter. registered 1 in 3.75, the power of the hand brake was proved in that it restrained the vehicle from running back. With the lowest gear available engaged I was then able to make an extremely smooth restart without difficulty and marvelled at the way the engine pulled away without the slightest trace of roughness or hesitation.

Descending the hill in neutral occupied t w o minutes, restricting the road speed to a maximum of 20 m.p.h. by the use of the foot brake. This is an extremely severe test, but at the bottom of the hill an emergency stop was made from 20 m.p.h. and this showed that the brakes had not faded in any respect. Apart from a slight smell of warm facings, there was little to indicate that this test had been made at all.

From the driver's angle, the Foden eight-wheeler with a two-stroke engine, power steering and air brakes is quite pleasant to drive once he has become accustomed to the high-pitched engine note produced at the high engine speeds required for maximum performance. In the case of the test vehicle, a tachometer (offered as optional equipment) was fitted and this proved useful in ensuring that the engine speed did not drop below 1,500 r.p.m. This was particularly important on hills because below this speed hill-climbing is not impressive and under such conditions it is imperative to change down before it is too late.

I was particularly pleased by the suspension of the vehicle, both when laden and unladen, and a good ride was obtained over indifferent surfaces. Furthermore. although the power steering allows the negotiation of corners at much higher speeds than would be expected of a vehicle of this weight, the suspension cuts out all traces of roll and instability.

-Although there is plenty of room on the driver's side of the engine cowl, the passenger's foot room is somewhat restricted by the large box which covers the twin oil-bath air cleaners. Ibis being directly Ahead of the passenger's seat.

Varibus maintenance tasks carried out at the Foden works showed the vehicle to be reasonably easy to maintain, particularly with regard to the engine. The first task was to check the water level and this occupied 4 seconds, following which the engine oil level was verified in 1 minute, this time including raising and lowering the near-side engine coWl and its quilted cover. Two gearbox-oil-level checks were made, the first being to use the dipstick which is provided with the optional powertake-off gear. This was done from, beneath the vehicle, although a floor trap is fitted in the body.

When a power-take-off is not supplied the gearbox oil level is checked by means of a combined filler and level plug and, working from below again, I checked the oil level, using this plug, in 21 minutes. A combined filler and level plug is provided in the rear-axle differential pot, the orifice being closed by a slotted cover, the two nuts of which need not be removed, allowing the level to be checked in 11 minutes.

The two oil-bath air cleaners are arranged to slide out from their box, each being secured by a single bolt. The box cover, however, is retained in place by 14 wing nuts to ensure dust tightness, and the whole sequence of removing the cover, checking the level in each cleaner, and replacing the cover, occupied 8 minutes.

A square-socketed plug is provided in the base of the steering box for level checking and filling purposes, and this is accessible from inside the cab. Checking the level in the box took 1 minute 10 seconds.

With the near-side engine cowl section up, I checked the steering servo oil reservoir in 10 seconds and then proceeded to remove number 5 injector, this taking 4 minutes. Replacement of the injector took a little longer--61 minutes—because I cross-threaded one of the union nuts. All in all, however, none of the fuel injectors is difficult to remove or replace, and the comprehensive tool kit includes the necessary special tools to -facilitate injector removal.

There are only two fuel filters inthe fuel system, these both being paper-element units located side-by-side ahead of the fuel tank op the near-side frame member. In this position they are particularly easy to work on, with a result that it took me only 1 minute to remove and 11 minutes to replace each element.

To ensure maximum accuracy, brake adjustment is best done with the wheels jacked up, uSing feeler gauges to check the facing/drum clearance. It takes 45 seconds to jack up each wheel, approximately 2 minutes to adjust each brake and 4 seconds to lower each wheel: Therefore all six brakes can be adjusted in under 20 minutes.

The chum-type transmission brake is a Girling unit and has the usual square-headed adjuster. Adjustment took 25 seconds.