A New Method o

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

Oil Filtration

A Neu) Smith Filter for Power Units; and an Oil-reclaiming Apparatus, Both of which Incorporate a Specially Prepared Paper Filtering Medium

I T is generally recognized to-day that A retains its lubricating properties, even though it may have collected a large quantity of impurities. Due to this fact the reclamation of used oil has received much attention from specialists and maintenance engineers.

In the issue of The C0172112erCial Motor dated June 9, 1933, we described a reclaiming apparatus, known as the Metafilter, in which

special filtering powder was ins troduced into the dirty oil Since that time much research work has been carried out by the maker, Metafiltration Co., Ltd., Belgrave Works, Hounslow, Middlesex, as a result of which a neiv apparatus is shortly to be marketed. In this case the filtering medium consists hi a specially prepared paper known as Mctafibre, so called because the M' etasil powder is mixed in the pulp of the paper.

At the same time it is of interest to note that a new filter for oil and petrol engines, embodying the same filtering medium, is to be marketed by S. Smith and Sons (Motor Accessories), Ltd., Cricklewood, London, N.W.2.

Taking first, the Smith oil filter for power units, this is of the by-pass type and is a highly efficient device. Throughout the life, of the element, which is approximately 10,000-15,000 miles, the oil is maintained in a thoroughly clean condition. When the element becomes clogged, the discoloration of the oil is easily discernible on the dip-stick and a new filter is required.

Accompanying illustrations show the construction of the device and one of the filter units. The latter comprises two discs of treated paper, the edges of which are crimped together, whilst each has a central hole, two brass washers separating one disc from the other at the centre. One washer has a number of raised pips on one face to space it from its fellow.

A number of these units is threaded on a perforated tube and comprises the filter pack. At the bottom of the tube is a compression spring to hold the units in position, and the whole is sealed into a container which carries the inlet and outlet nozzles.

Oil entering the container must pass through the filter units, then between the two papers and through the washer spaces to the central tube and so back to the sump. It is claimed that the Smith filter returns absolutely clean oil to the sump, the Meta.fibre being capable of collecting even colloidal carbon which is, of course, more finely divided than the abrasive impurities in the oil. An analysis of the slime deposited on the papers of one of these filters after 7,000 miles in service showed that a total of 122 grammes of oil-fuel residue had been extracted from the lubricant.

An Oil-reclaiming Apparatus with a Metafibre Filtering Medium.

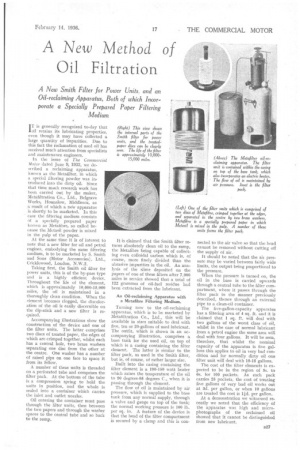

Turning now to the oil-reclaiming apparatus, which is to be marketed by Metafiltration Co., Ltd., this will be available in sizes suitable to deal with five, ten or 20-gallons of used lubricant. The outfit, which is shown in an accompanying illustration, comprises a base tank for the used oil, on top of which is a casing containing the filter element. The latter is similar to the filter pack, as used in the Smith filter, but is, of course, of rather larger size.

Built into the casing containing the filter element is a 100-150 watt heater which raises the temperature of the oil to 90 degrees-95 degrees C., when it is passing through the element.

The flow of oil is maintained by air pressure, which is supplied to the base tank from any normal supply, through a valve and gauge on top of the tank; the normal working pressure is 100 lb. per sq. in, A feature of the .device is that the head of the filter compartment is secured by a clamp and this is con

nected to the air valve so that the head cannot be removed without cutting ofl the supply of air.

It should be noted that the au pressure may be varied between fairly wide limits, the output being proportional to the pressure.

When the pressure is turned on, the oil in the base is carried upwards through a central tube to the filter compartment, where it passes through the filter pack in the manner previously described, thence through an external pipe to a clean-oil container.

The five-gallon-capacity apparatus has a filtering area of 4 so, ft. and it is claimed that I sq. ft. will deal with two gallons of the worst class of oil, whilst in the case of normal lubricant Irons a petrol engine the same area will deal with four gallons. It will be seen, therefore, that whilst the nominal capacity of the apparatus is five gallons this applies to oil in very bad condition and for normally dirty oil one filter unit will deal with 10-15 gallons.

The cost of the filter elements is expected to be in the region of 5s. to Os. for 100 pockets. As each pack carries 25 pockets, the cost of treating five gallons of very bad oil works out at Sd. per gallon, or when 10 gallons are treated the cost is 1-id. per gallon.

At a demonstration we witnessed recently we noted that the efficiency of the apparatus was high and microphotographs of . the reclaimed oil showed that it cannot be distinguished from new lubricant.