TESTING HIGHWAY ENDURANCE.

Page 9

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

Trying to Wear Out "a Roadway Quickly by Subjecting it to the Equivalent 01 15 Years' Normal Traffic.

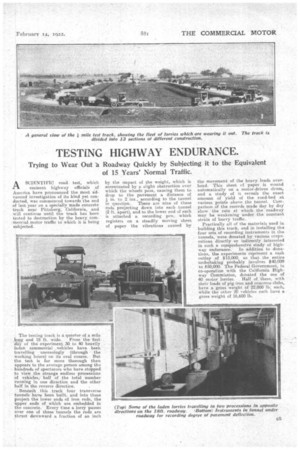

ASCIENTIFIC road test, which eminent highway officials of America have pronounced the most advanced investigation of its kind yet conducted, was commenced towards the end of last year on a specially made concrete track near Pittsburg, 'California, and will continue until the track has been tested to destruction by the heavy, corn* ,mercial.motor traffic to which it is being subjected.

The testing Wick is a quarter of a mile long and 18 ft. wide. From the first day of the experiment 30 to 40 heavily laden commercial vehicles have been travelling unceasingly (through the working heurs) on its oval course. But the test is far more thorough than appears to the average person among the hundreds of spectators who have stopped to view the strange endless processions of vehicles,/ half of the total number running in one direction and the other half in the reverse direction.

Beneath this track four transverse tunnels have been built, and into these project the lower ends of iron rods, the upper ends of which are embedded in the concrete. Every time a lorry passes over one of these tunnels the rods are thrust downward a fraction of au inch

by the impact of the weight, which is accentuated by a slight obstruction over which the wheels pass, causing them to drop to the pavement a distance of 1 in. to 2 ins according to the tunnel in question. There are nine of these rods projecting down into each tunnel (2 ft. apart), and to the lower end of each is attached a recording pen, which registers on a steadily reeving sheet of paper the vibrations caused by

the movement, of the heavy loads overhead. This sheet of paper is wound automatically on a motor-driven drum, and a study of it reveals the exact amount of yield of the road-bed at various points above the tunnel. Com-, parison of the records made day by day show the rate at which the roadway may be weakening under the constant strain of heavy traffic.,

Practically all of the materials used in building this track, and in installing the four sets of recording instruments in the tunnels, were donated by various corporations directly or indirectly interested in Such a comprehensive study of high\Nay endurance. In addition to donations, the experiments represent a cash outlay of $15,000. so that the entire undertaking probably involves $40.000 to $50,000. The Federal Government, in co-operation with the California Highway Commission, donated the use of 40 motor lorries. Half of these, with their loads of pig-iron and concrete slabs, have a gross weight of 22,000 lb: each, while the other 20 vehicles each have a gross weight of 16,600 lb.

Some idea of the cost involved in making this practical test of road surfaces is gained from the fact that the lorries, of which there is an average of 32 in operation simultaneously, consume about 506 gallons of petrol daily.

Approximately 80,000 tons of load pass over a given point on the road in every two-minute period that the machines are in operation. It is estimated that the average sections in the •oval track will be subjected to an equivalent of 15 years of normal travel before.the experiment has been completed. •

The 13 sections of roadway into which the 1,372 ft. of track are divided vary in length from 45 ft. to 150 ft., and likewise vary in the manner of construction. Section A, for example, is 5 ins, thick, reinforced with in. structural grade steel bars, placed in the centre of the slap, 18 ins, on centres. The slab is built on loose rock, with adobe sub-grade beneath. Section.F is 8 ins, thick, with no reinforcement, and constructed with two inverted curbs 12 ins. deep. Section G is 6 ins. thick reinforced with 1 in. special grade steel bars placed in

top and bottom of slab. The other sections show corresponding variations in construction. At the time of cleepatch of this article from Los Angeles, California, the tests were still in progress. While the demonstration appears to he an expensive one, the interested engineers point out that it should result in the saving of hundreds of thousands, if not millions, of dollars, to the country as a whole, for the various types of construction are being given an actual-wear test which has never before been attempted in a scientific manner.