For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

13BIZE OF TRY SHILLINGS is awarded each week all others are paid for at the 9-ate of a penny a haw, with an published. Mention your employer'sname, in confidence, Commercial Motor." 7-15, Ros Lamps Alight— Light your lamps at 5.43 in London, 6.15 in Edinburgh, 5.42 in Newcastle, 5.50 in Liverpool, 5.48 in 'Birmingham, 6.53 in Bristol, and 6.35 in Dublin.

Improving a Worn Suspension of a Gearbox.

The sender of the following communicatiom has been awarded -the 10s. prize this week.

[1828] "E.O.W." . (Birmingham) writes-:—" The gearbox on a, wagon which is in my charge is suspended fore and aft from tr, coupleof eye bolts, which are carried in cross-members en the frame. A short

torque rod at one side of the box prevents it from swinging in these bolts. In course of time, these eyebolts wore. As a. result, there was a, tremendous clatter every time the footbrake was used or every time the clutch was engaged or disengaged. It was clear that this wear was likely to increase very rapidly in these circumstances, and an immediate repair was, therefore, decided upon.

"The repair of the bolts where they enter the erossmember was not a difficult, matter.It was merely necessary to enlarge the holes in the frame and provide the bolts with sleeves to fit, What to do with the holes in the eyebolts into which the gearbox fitted was somewhat of a puzzle. They were rather large in diameter, and it did not seem sale to re-bore the holes for bushing purposes, as the metal did not appear thick enough to allow of this. Similar reasons served to prevent our turning down the journals on the gearbox. Eventually it oecurred to someone that this might be treated. by heating the inside of the hole to a bright red, keeping the outer portion cool, and then suddenly plunging the whole into water. One application of this cure, although effective in reducing the diameter of the hole, did not prove to be sufficient, but after carrying \out the operation three times we were successful. The gearbox suspension was then as good as new."

A Quick Repair to a Daimler Car.

[1829] "H.M." (West Bromwich) writes :—" VTo effected a rather smart • repair to a Daimler vehicle the other day, the description of which may be of interest to your mechanic readers. The car turned into the yard at exactly 9,45 a.m., .9,,nd there was clearly something the matter with the near-side front wheel. It was squeaking away to a fine tune, and the hub, on examination by the usual method, was discovered to be unbearably hot.

"The wheel was promptly removed, and it was then seen that a large ball bearing wan smashed to atoms. The balls were split, the cage ground almost to powder, the distance piece between the bearings almost unreeognizable, and the axle arm. itself badly scored.

• "The first and obvions procedure was to telephone to the works for replace parts. The maker could not

to the sender of the best letter which we publish on this page allowance for photogra49h.s. All notes are edited before being

as evidence of good faith, Address, D., M. and "The ebery Avenue, London, B.C. 1.

do anything without the old parts as patterns, arid they "were accordingly sent off by special messenger on the 2 p.m. train to Birmingham. Unfortunately the maker had neither an axle arm nor a ball bearing of the right size in stock. The best they could offer was a ball bearing a size smaller than the standard, and the advice to us that we should turn down the old axle to fit the new bearing. • "This was done during the night, and everything appeared to be going well until the next morning, at seven oclock, when, on proceeding to erect, it was found that the new bearing was too small for the axle housing. The car was due out at a quarter to nine, so that if we were going to be to time some satisfactory expedient had to be devised, and quickly, too.

"The broken ball bearing had split circumferentially, _forming two narrow rings, and it occiirred to me that if these were .seftenect they could be bored out so as to form suitable liners for the: new bearing. No sooner thought of than carried into -effect, 41'hey were ready for assembly by 8.30; the wheel replaced, and the car ready to go out by ten minutes past nine, only 25 minutes behind time, a remarkably quick job in the opinion of all who saw the breakage and Who knew what we had to do.

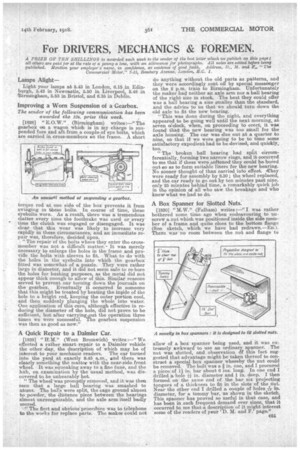

A Box Spanner for Slotted Nuts:

[1830] "M.W." (Fulham) writes :—" I was rather bothered some time ago when endeavouring to unscrew a nut which was positioned inside the side member of a frame and quite cloes to the bottom flange (See sketch, which we have had redrawn.—En.). There was no room between the nut and flange to allow of a box spanner being used, and it was extremely awkward to use an ordinary spanner. The nut was slotted, and observation a this fart suggested that advantage might be-taken thereof to construct a special box spanner whereby the nut could be. removed.. The bolt was a in. one, and I procured a piece of 11 in. bar about 6 ins. long. In one end I drilled a-hole in. diameter and 1 in. deep. I then formed on the same end of the bar six projecting tongues of a thickness to fit in the slots of the nut. Near the other end I drilled a couple of holes -7r, in. diameter, for a. tommy bar, as shown in the. sketch. This spanner has proved so useful in that ease, and has been in such frequent demand ever since, that it occurred to me that a description of it might interest some of the readers of your 'D. M. and F.' page."